We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Greene and Greene-Style Hall Table

?Exquisite detailing turns

ordinary into extraordinary.

By Bruce Kieffer

| Choose your best boards for the top. Look for boards with similar grain and color. With luck, the joints will be almost invisible on the finished top. | Click any image to view a larger version. |

| Rout a tongue groove on the breadboard ends using a slot cutter. These boards help the top stay flat. Featherboards make routing safer and more accurate. |  |

| Square the ends of the plug grooves with a mortising machine chisel. A wooden mallet prevents damage to the top of the chisel. |  |

| Mark the screw holes’ location on the top by lightly tapping the screw heads. Make sure the breadboard ends are centered on the top. Remove the breadboard end and drill the pilot holes in the top. |  |

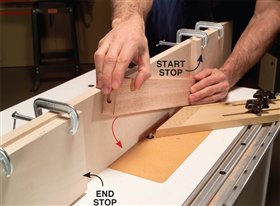

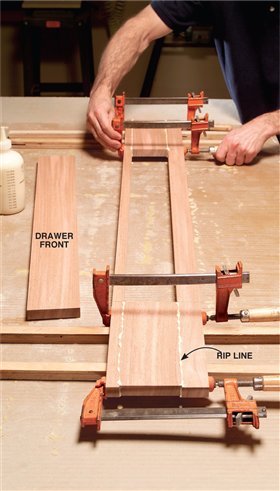

| Glue the front apron back together after it’s been ripped and crosscut into five pieces. Because the drawer front is cut out of the apron, it seamlessly blends into the surrounding pieces. |  |

| Join the apron to the legs with biscuits. Offset the joint by placing a 1/4-in.-thick spacer under the biscuit joiner’s fence when cutting the aprons. Remove the spacer for the legs. |  |

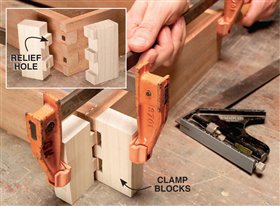

| Glue and clamp the base together. Two 10-in.-tall L brackets are like having an extra pair of hands to support the front assembly as you apply the clamps. |  |

| Glue the drawer kickers and runners into place. Create the long grooves on the ends of each piece with a 5/32-in. slot cutter. |  |

| Rip the ebony into strips on the bandsaw. It’s safer than a tablesaw and wastes less of this expensive wood. A fine-toothed saw blade makes a smooth cut that requires minimal sanding. |  |

| Cut short plugs after sanding the gently rounded shape on the end. A simple wooden jig holds the ebony strips in place. |  |

| Tap the plugs into their holes. The plugs stand slightly proud of the surface. Use a spacer made from plastic laminate to make sure all the plugs are equal in height. |  |

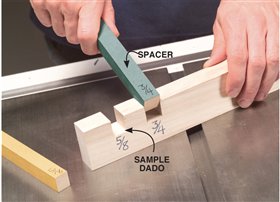

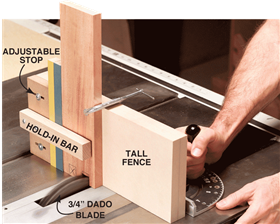

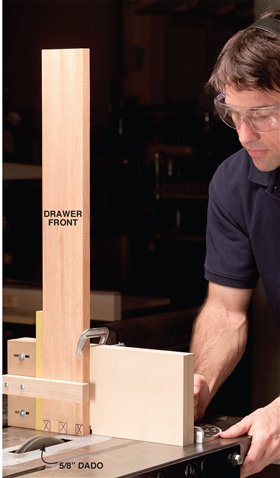

| Add two more spacers for the second cut on the drawer sides. |  |

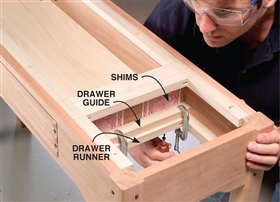

| Screw guides to the drawer runners with the drawer in place. Create the perfect gap between the guides and the drawer sides with two playing-card shims. |  |

| Screw the base to the top. Make your own “sideways” screwdriver with a ratchet wrench to get into this tight space. Use a 1/4-in. socket and a screwdriver bit from a cordless drill. |  |

| This story originally appeared in American Woodworker July 2004, issue #108. |

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Recommended Posts