We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Smooth-Cutting Hole Saw

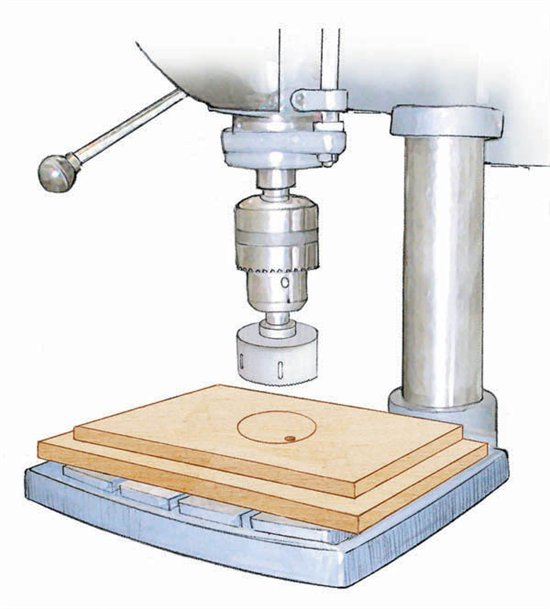

I cut a lot of discs and large-diameter holes in my shop. I was puzzled for the longest time because I was getting vibration and smoke. It even happened with new hole saws.

Eventually, it dawned on me that the culprit wasn't my antiquated drill press, but the simple fact that a hole saw doesn't clear its own chips very well. Give those chips a place to go, and they won't clog up the saw!

My easy solution is to predrill a 3/8" or larger hole in the edge of the waste, next to where the saw will cut. Drill this escape hole all the way through the workpiece, and into the waste board. Now the chips have a place to go. They fall away from the saw teeth and into this hole. This allows the hole saw to spin without the least bit of chatter.

Paul Williams

My Take

I'd go a step further and drill several holes in the waste side. The important thing to remember here is to make sure the holes are on the waste side. If you're making holes, drill on the inside of the circle. If you're making discs, drill on the outside. To get the placement of these extra holes just right, start the hole saw just enough to mark the circle, and then drill your extra holes.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.