We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Face Frame Cabinets

Master these

techniques to

open up a world of projects.

By George Vondriska

|

If you can make dadoes, rabbets and face frames,

you can make almost any cabinet. Master this

foundation of skills and you’ll be ready to launch

into complex variations of the simple cabinet

shown in this story. Here’s how:

Face-frame cabinets are little

more than plywood boxes covered

by a solid-wood frame. The

frame adds strength and rigidity

to the box, while covering the ugly

plywood edges. In this story I’ll

take you through the building of

a typical freestanding wall cabinet.

The concepts and techniques can

also be used for kitchen cabinets,

bathroom vanities and bookcases.

There’s plenty of room for mistakes,

and I’ve made them all over

the years. To stay in business,

and provide my students with

shortcuts to success, I’ve developed

systems for avoiding these

kindling-producing errors.

|

|

You may also like…

Sycamore Pantry

Shaker Sideboard

Cherry Pie Safe

|

|

Dado the case sides to receive the cabinet

bottom. Be certain the dado head is set up correctly

for your sheet stock. The shelf should slip

into the dado with no more than hand pressure, and the

parts should stick together when you try to separate them.

Setting up the dadoes can be fussy, and may require dado

shims (thin material that allows you to change the width of

the head a few thousandths of an inch; see Sources). Take the time to get it right. The correct depth for

dadoes and rabbets is one-half the thickness of whatever

they’re being cut into. 3/4-in. plywood gets a 3/8-in. dado.

Caution: The blade guard must be removed

for all of these dado blade cuts. Be careful.

|

|

Click any image to view a larger version.

|

|

Rabbet the back edges of the case sides, top

and bottom to receive the back. Use the procedure

shown in Photo 4 to make the rabbets slightly

deeper than the back requires. Don’t disassemble the dado

head for this thinner material, just bury part of the head in the

sacrificial fence.

|

|

|

|

Assemble the

case, keeping the

front edges flush.

Clamp pads protect

the wood surface. Old plastic

honey bottles make great glue

bottles—just keep them out

of the reach of children. Use

just enough glue in the joint to

cover the surface; it’s just like

applying paint.

|

|

|

|

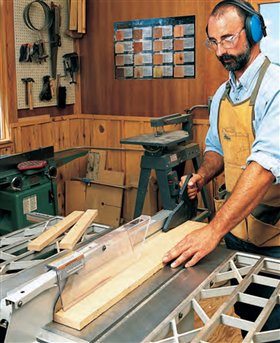

Rip the face frame pieces to

width with a jointed edge against the

fence. Make them 1/16-in. wider than

the finished size so the sawn edge can be cleaned up.

Use a push stick for these narrow pieces. My rule of

thumb for keeping both thumbs is to use a push stick

on rips less than 3-in. wide.

|

|

|

|

Use screw pockets to join the rails

to the stiles. Face frames can be joined

by dowels, mortises and tenons, minibiscuits

or simple, fast, effective screw pockets. Mark

the rail faces and be sure the holes get drilled only in

the backs of the rails. Incorrectly flipping parts around

has put some rails in my scrap pile.

|

|

|

Oops!

It’s a temptation to cut the face frame exactly

the same size as the case. Unfortunately, this

often leads to disaster. When you glue the

face frame on, it often slips sideways a bit,

so you can end up with the unfortunate and

unfixable result shown at right. The solution is

to build the face frame slightly oversize, as we

show in Photos 13 and 15.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.