We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Display Cabinet

Open sides and built-in lights showcase your treasures.

By Randy Johnson

|

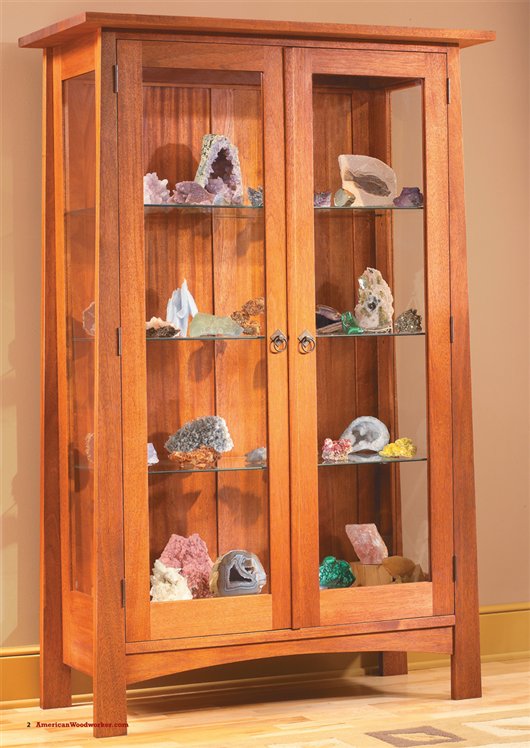

Some cabinets are all about displaying the beauty of

wood. This cabinet, with its glass doors, shelves and

sides and built-in lighting, is all about displaying

what’s inside. Whether it’s your collection of antique tools

or fine porcelain, whatever you put inside is sure to shine.

|

|

You may also like…

Show Case

Sliding Door Bookcase

Modern Mission Cabinet

|

|

Rough cut the stiles for the sides, back, doors and legs. Make a

couple extra pieces of each part in case a couple end up warping badly.

|

|

Click any image to view a larger version.

|

|

Let your roughsawn

lumber rest

for at least 48 hours.

Spread out the parts

so air can freely

circulate around them.

Most wood has a

tendency to warp or

twist a little after it is

rough sawn. Letting

your rough parts rest

allows them to

stabilize before you do

the final dimensioning.

|

|

|

|

Joint and plane the parts. Let these parts rest for a few days as

well. Then use a straightedge to check for flatness. Pick the straightest

and flattest boards for the doors.

|

|

|

|

Use a tongue-and-groove joint for the

side and back frames. The groove is quick to

make on your router table, and the tongue can

be cut with a dado head on your tablesaw.

|

|

|

|

Assemble the side panels on a flat bench. Check for twist by sighting

down a pair of winding sticks, which are simply a matching pair of straight

boards. Adjust the frame in the clamps until the sticks are parallel.

|

|

|

|

Glue the tapered legs to the assembled side frames. The legs should

be flush with the inside of the side frames. Sand the panel side of the legs

and the outside of the side frames before gluing these parts together. If

you get any glue squeeze out at these inside corners make sure to clean

it up with a damp rag before it dries.

|

|

|

|

Rout a rabbet around the inside of the side panels for the glass. The

router leaves rounded corners, so cut them square with a chisel.

|

|

|

|

The tongue-and-groove

joints at

the corners of the

box frames provide

positive alignment

for clamping.

|

|

|

|

Glue and clamp the box frames. Make sure they are perfectly square

and flat, because they determine how square and straight the cabinet

ends up.

|

|

|

|

Dry fit the box frames to the side frames. Once you’re sure the parts fit square and true, add

glue and leave everything clamped until completely dry.

|

|

|

|

Assemble the frame-and-panel back. First clamp the center

stile and top and bottom rails. Then add the panels and the side stiles.

Take a dry run at this assembly before actually gluing it.

|

|

|

|

Screw the back to the top and bottom box

frames. Add a mending plate along the side to

hold the back to the side leg.

|

|

|

|

Slide the bottom in place. The bottom is screwed at the front

through the front support board and held at the rear by a dado in the

back panel. The dado is 1/8" extra deep to allow the bottom to freely

shrink and expand.

|

|

|

|

Drill the holes for shelf pins. Using a shopmade

template and a self-centering drill bit

makes this simple and accurate. Align the

template with the inside edge of the side stiles.

|

|

|

|

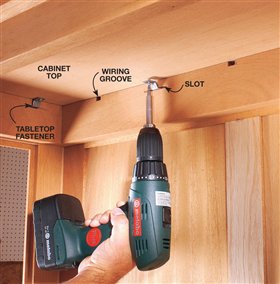

Attach the solid-wood top with tabletop fasteners. This allows the

top to expand and contract without cracking. The slots can easily be cut

with a plate joiner. Note that wiring grooves have already been routed in

the top of the box frame and back.

|

|

|

|

Install the low-voltage lights. This style of light is typically made

up of a bezel, a bulb and reflector, and the lens. The transformer and

switch are then attached to the back of the cabinet.

|

|

|

|

Drill mortises in the door stiles. Center the mortise bit right in the

middle of the groove.

|

|

|

|

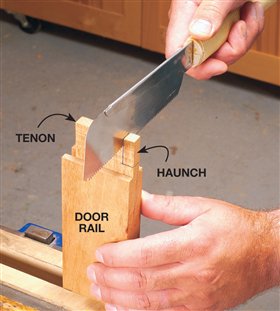

Saw the haunch on the door rail tenons.

The haunch will fit into the groove in the door

stile and stiffens the mortise-and-tenon joint.

|

|

|

|

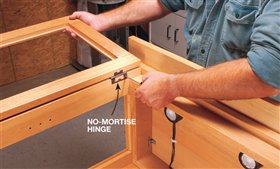

Attach the doors with no-mortise hinges. Put the door in its closed

position and mark for the location of the hinges. The doors will likely fit

snug at the top and bottom, and that’s okay for now. Open the door and

install the no-mortise hinges. Because you don’t have to fuss with making

mortises, their nickname is “the frustration-free hinge.”

|

|

|

|

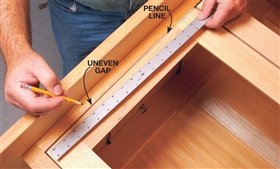

Check the clearance gap along the top and bottom of the doors.

Use a ruler as a guide and draw a pencil line for an even gap. Then

remove the doors and belt sand to the pencil line.

|

|

|

|

Install the glass and retainer strips after you have stained and

finished all of the cabinet parts. Predrill small holes in the retainer strip

and then use a brad pusher to install the small brads. The brad pusher is

a lot safer than a hammer around glass.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.