We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Building Your Canteen

Building Your Canteen

Materials

1⁄2″ thick lumber – 48″ long

1⁄4″ thick plywood – 10″ x 20″

1 each, 2″ wide cotton/linen carrying strap

1 each, 2″ strap buckle (optional f/ carrying strap)

2 each, 3 1/2″ long x 1⁄2″ wide leather pieces or steel strap

1⁄2″ leather banding or steel strap (for the hoops)

20-24 each, ½” or 7/16″ long, upholstery tacks (for “hoop” trim and carrying strap)

Cutting the Staves

Cut your staves from a 1⁄2″ thick piece of square lumber. If the piece is long enough you may only have to do this once and create all the staves from one piece of lumber. You may substitute shorter pieces and repeat the cut. Set your table saw blade to cut at a 15-degree angle and rip down one side, creating your first bevel. Adjust the table saw fence to the “Stave Outside Width” of the stave you selected in part 1 (3/4 gallon or 1 quart). Flip the board where the bevel is facing down and is against the fence of the table saw. Rip the second bevel in the long piece of lumber. Now you should have a long piece with a 15-degree bevel on each long side in sort of a “V”. The ends of the lumber are still at 90 degrees.

Stave segments cut at 15 degrees.

We will now cut the individual (12) staves. The stave wood grain goes along the length of the stave.

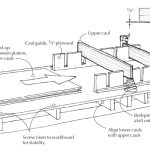

Warning – Do Not Crosscut with The Rip Fence – Instead, use a miter gauge or a crosscut sled.

You have to make your staves with cross cuts into several pieces of identical length. DO NOT use the rip fence as a supporting barrier for crosscutting. You can clamp a stop block to the fence for accurate measurement of length and use the miter gauge to guide your stock through the blade. This way, you eliminate the risk of your workpiece getting squeezed between the fence and the blade.

Set your table saw fence block to be 4 inches from the blade, and use the miter gauge on the table saw to hold the lumber perpendicular to the blade. Cut a small piece from the end of the lumber piece to balance the cut, and rid it of any roughness or splits. Check for squareness of this end cut. Then make the 12 staves with a crosscut.

Cutting the Top and Bottom Stave Channels

You can make the channel for holding the canteen top/bottom with a router or your table saw. After you have to cut each stave to 4″ in length, then return to the table saw or router and cut a 1⁄4″ channel on the “Stave Inner Width” ends (Bottom of the mitered “V”). The channel is 1⁄4″ from the end and is 1⁄4″ deep. The stave length must have the grain running on the long edge. You can use several methods to cut the channel;

- You can make several passes of the stave on the table saw to cut the channels. Set where you want the cut on the table saw, set the blade height to 1⁄4 inch, cut a pass on each piece on each end. Make successive cuts until you get a channel (rabbet) 1/4″ x 1/4″.

- Use a table saw with a dado blade, 1⁄4 inch stack set to 1⁄4 in height. If you have this, you probably know how to use it as well.

- Use a router – assuming you have one you probably know how to use it for this project and I won’t detail it here.

Stave channels being fitted to the top and bottom panels

Cutting the Top and Bottom Panels

The top/bottom panels have to be built but if you can rely on the schematic image the panel may not fit, as this is the overall diameter, not allowing for the channels to hold the top/bottom in place. It is best to dry assemble your canteen with blue painters tape, and measure the inside channel across the opposing channel to ensure a tight fit.

Everyone has their way of cutting a circle using various templates, jigs, compass drawings and so forth. Use a band saw or jig saw to cut the circle as accurately as you can. Take two pieces of 1⁄4″ Plywood about 9 x 9 inches square. Use some double-sided tape to adhere the two pieces together. This allows you to cut both top/bottom panels at once. Sand the edges smooth and sand the surfaces before assembly and finishing.

Test the fit of the round panels with the dry fit you did earlier with blue painter’s tape.

Building a Spout and Stopper

Spout with stopper.

The Spout

I have a wood lathe so I can get creative in making a spout for the canteen. In the original drawings, the spout is square and not very detailed. To keep it simple, a block is angularly cut, and affixed to the top stave of the canteen with a snug fit and some glue. The hole is abou 5/8″ in diameter. After the spout is affixed to the stave, a tapered hole can be made with a step drill,or an angled rasp after the hole is drilled.

Step drill bits and tapered rasp for rotary drill

The Stopper

A wine bottle cork could work, but it is not tapered and runs the risk of falling into the canteen. You do not have to have a wooden end on your stopper, but it adds some security in keeping it with the canteen. I made a fancy walnut knob to attach my stopper to the canteen with a leather cord. My knob is a hole drilled through horizontally, to tie the lanyard. You can use almost any shape of wood to your liking and drill a 3/8-inch hole for affixing a piece of wood dowel rod. Glue the dowel rod into the knob. Drill a 3/8-inch hole into your tapered cork but do not go all the way through. Leave about 1⁄4 inch in the base. Measure the cork hole depth, cut the dowel to the length and glue the cork to the dowel. You may have to adjust the canteen spout hole to accommodate the cork depth of fit. I bought a package (4ea) of tapered corks at Hobby Lobby, and cut about 1/8″ from the wide end so the assembly would look better in the spout. Use a piece of leather lacing to secure the stopper to the spout.

Cork stopper with walnut wood handle

Assembling the Canteen

NOTE: If you plan to carry water in your canteen, that is its purpose, you may want to do some waterproofing. After all, this is a reproduction, not a “barrel-pressed” hoop-staved container. If waterproofing is wanted, see the section below.

Use a board to align you staves against. Roll out blue painters’ tape, and place the outside of the stave onto the blue tape. When all the staves are in place, apply glue to the stave mitered joints and to the channels. Place the top and bottom panels near the center of the row of staves. You can then roll the painters tape stave “chain” up and around the top/bottom panels. Secure with tape, bands or straps until the glue is completely set.

Shaping the Mitered Outside Corners

Shaping the Mitered Outside Corners

After assembling the canteen and all the glue is dried completely, you can begin shaping the 12 sides into a rounder appearance. If you have a belt sander or even a powered sander this can be done very quickly on soft woods such as pine. If you do not have powered gear, a wood block and fresh sandpaper will also work. You probably will do finer details with a sanding block as well. Do not forget to sand the end grain of the staves smooth. Begin with the 120- grit sand paper and progress to 220-grit, and finer grits if desired. Judge by eye and touch for roundness, and sand down the bumps and ridges that are noticed.

Waterproofing your Creation

You will have an easier time applying the hot paraffin to the inside for waterproofing after the canteen is assembled and sanded to the round cylindrical shape. It is my theory, that any polyurethane, epoxy, paint or other coating may not bond entirely, or peel off the wood when in long/continuous contact with a liquid, so I used melted paraffin. Beeswax could also be used instead but it imparts a bit of flavor to the contents. If you are drinking mead, this may be desirable. Keep in mind that alcoholic beverages can also damage some wood finishes. Brewers pitch is also used, but is hard to find, expensive, and messy to work with.

Fortunately, I have an old Crock-Pot that I have used on other projects needing melted wax. If you don’t have a Crock-Pot, use a double boiler to melt the wax evenly. Both paraffin and beeswax have low melting points and are also flammable and the double boiler technique will mitigate the risk of a flare up, and melt the wax evenly. A double boiler can be a normal household cooking pot with boiling water, and a scrap tin/metal can to hold the wax. Use a funnel in the canteen spout of the canteen to pour the melted wax inside. When applied or poured, the wax will remain liquid a bit, but don’t wait too long. You are only wanting a coating on the sides. Insert the stopper, and roll the canteen about to evenly coat the insides, and pour out the remaining melted wax, back into the metal can. It doesn’t take long, as the wax will begin to solidify as soon as it touches the surfaces inside. I recommend finishing the outside completely before coating the inside, so if you happen to spill a bit of paraffin on the outside, your stain/finish will still adhere properly.

Sanitation and Hygiene as Applied to Canteens

The use of polluted water is a factor dangerous to health and accounts for the prevalence of disease in localities where other sanitary conditions are beyond reproach. It is the part of wisdom to remove the danger of possible contamination by the use of a canteen which can be completely emptied, drained and even sterilized.

There can may be enough places for germs and micro-organisms to make the use of the canteen. Recommend sanitary conditions be observed to sterilize your canteen in a way as not to damage the wood or melt the inner paraffin coating with excessive heat.

Do not store the canteen with water inside. Empty and air dry when not in use.

Applying the Outside Wood Finish

Applying the Outside Wood Finish

There are a wide variety of ways to finish the outside of your canteen. Depending upon how well the plywood top/bottom pieces match the wood staves, this could be a design enhancement or detractor. If you use soft pine wood for the staves, the color variation of the staves compared to the top/bottom panels could detract from your design. Linseed Oil is used on tool handles such as axes, adze, shovels ect. For a reason. It allows inspection of the wood for splitting, where such defects my not be detectable under a coat of paint. Linseed Oil is inexpensive and makes a long-lasting finish. It imparts a soft yellow hue to the wood, and can be applied with a folded cloth. If you want a darker color to help in color matching the wood, you should stain the wood first, prior to applying the Linseed Oil or your chosen final finish. Some polyurethane finishes include stain in a range of color choices, which would provide a durable finish as well.

Methods of Carrying a Military Canteen – from The History of the Military Canteen

Attaching Hoop and Strap Guides Ornamentation

We know we are not blacksmithing hoops for our vessel, and a reproduction quality or solution is needed. As shown below, the “hoops” could be fashioned from 1⁄2-inch steel strapping often used for shipping heavy crates. Measured and cut to length it would make an attractive replacement for hoops. Steel strapping is available at Amazon and other retailers, but short lengths are quite expensive. Most retailers and transporters use plastic/nylon strapping, the steel strapping is hard to find by dumpster diving. Nevertheless, you may find a business or friend who has access to some.

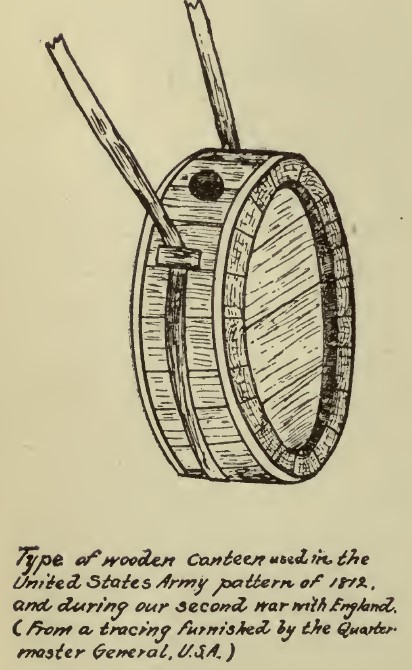

1874 Model of US Army Canteen, From History of the Military Canteen (Nov- 1900)

Period canteens were also “hooped” with wood and leather reinforcement. Or, you may find a suitable banding material that could be attached to your canteen, that could be painted to appear as metal or perhaps covered with a metalized tape. In the title picture I used ½” wide leather banding/strips secured with round head upholstery tacks. You will need ½ or 7/16 length tacks, so as not to completely pierce the staves. You have to see what is available to you and what works for your Uniform Kit.

The strap guides could be of metal, or leather affixed to each side. The L&C diagrams show the blacksmith/forged guide piece as fitted under the hoops and bent to be held in place. I am sure there are many variations. For our purposes, tacks can be used to attach the guides to the canteen. Just make sure the tack will not split the wood or pierce the canteen staves creating a leak.

Attaching Carrying Strap

I bought 2-inch-wide Thick Heavy Cotton Webbing on Amazon. You could easily make a strap from white cloth of the same width, or leather. Mimic the strap you use on your haversack and it will create are more balanced look for your uniform.

I also found a 2-inch-wide brass slide buckle at Hobby Lobby that is affixed to the strap as an adjuster. The strap is placed under the round bottom edge of the canteen, with the strap threaded through the guides on each side. If using a strap without a buckle or adjuster, you can secure the ends of the strap under the guides (left or right) with short tacks.

Summary

Summary

Most of you probably are familiar with woodworking and only needed the diagram tables for making your own canteen for your Uniform Kit. This may also provide you guidance and ideas for dressing up or building your Canteen Kit, if you want to buy one. I have enjoyed my research, and learned a bit. But I enjoy working on crafts in wood and plan to provide other period items in the future.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Building Your Canteen

Building Your Canteen