|

Here’s a compact work table

that you could tuck away in a

corner or use as a central

island for daily activities. It’s the same

height as standard kitchen countertops,

so it’s perfect for food preparation and

other standing chores.

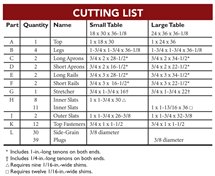

The Cutting List below has two

sets of dimensions; one for the 18-in.by

30-in. table shown here and another

for a larger 24-in.by 36-in. version.You

can easily build either table in a couple

of weekends. You’ll need a tablesaw, a

stacked dado set, a bandsaw or saber

saw, a drill press and a chop saw.You’ll

also need a plunge router to cut the

mortises and the curves on the rails.

Use your favorite hardwood, but

substitute hard maple for the top if you

plan to use it as a cutting surface. To

make the smaller version, you’ll need

about 12 bd. ft. of 5/4 stock for the top

and slats, four 3-1/2 ft. lengths of 2-in.

square stock for the legs and 5 bd. ft. of

4/4 stock for the aprons, rails and

stretcher. For the larger version, you’ll

need 20 bd. ft.of 5/4 and 7 bd. ft.of 4/4

stock. If you don’t have a jointer and

planer, have your lumber milled at the

lumberyard.

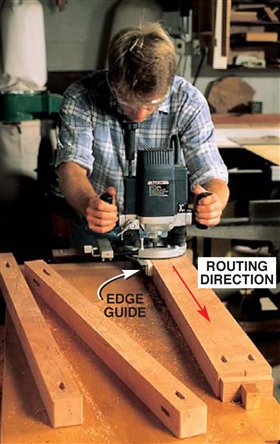

Mortise the Legs

When laying out the legs, orient the

end grain in a pleasing pattern because

it will be visible at the corners of the

finished top.Plunge-rout the mortises,

using an edge guide for your router

and a 3/8-in.-dia. up-cutting spiral bit

(Photo 1).

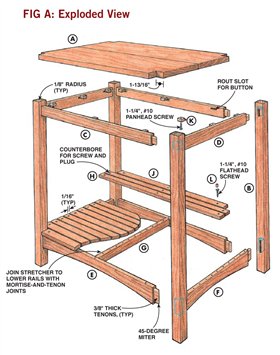

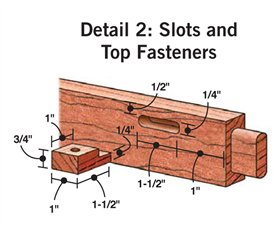

Once you’ve cut the mortises, switch

to a 1/4-in.-dia. straight bit and plungerout

the slots in the aprons for the top

fasteners, using the same gang-cutting

method (Fig.A,Detail 2).

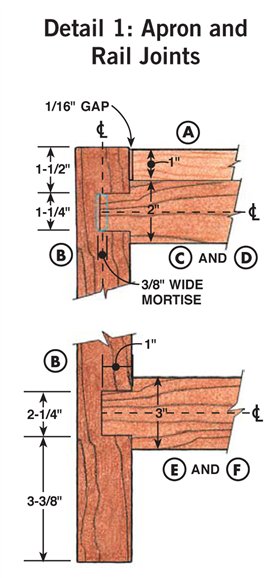

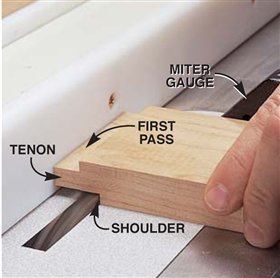

Tenon the Aprons and Rails

Cut tenons on the tablesaw using a

carbide-tipped,stacked dado set (Photos

2 through 4). Any roughness on the

tenon cheeks left by the cutters can be

removed with a chisel or rabbet plane.

After the tenons are cut and mitered,

round their shoulders (Photo 5).

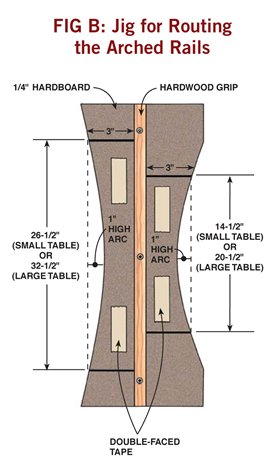

Rout Curves

The shallow curves on the lower rails

keep the table from looking bottomheavy.

Rout them with the help of a

double-sided, shop-made jig (Fig. B).

First, use the jig to transfer the curves

onto the rails. Saw the profiles, slightly

oversize, on a bandsaw or with a saber

saw.Then attach the rails to the jig and

rout the curves (Photo 6).

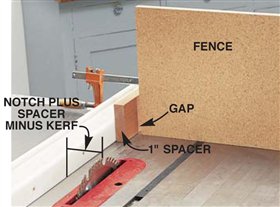

Notch the Top

The top is notched to fit inside the legs.

Leave a suitable gap (min. 1/16 in.)

around each leg so the top has room to

expand during humid conditions (Fig. A, Detail 1). With the proper setup, these

notches can be cut safely and precisely

on the tablesaw (Photos 7 and 8).

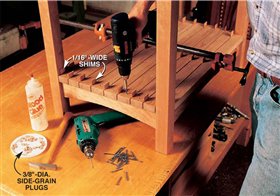

Attach the Slats

Mill all of the slats and drill

counterbored access holes for screws.

To space the slats evenly, lay them in

place on the lower rails with 1/16-in.-

thick shims in between (Photo 9). You

may have to joint a couple of slats or

add pieces of masking tape to some of

the shims to make everything fit.

With the shims in place, align the

ends of the slats and clamp them all

together. Drill pilot holes into the rails

and fasten the slats with screws. Fill the

screw holes by gluing in side-grain

wooden plugs (see Sources, below).

When the glue is dry, pare and scrape

the plugs flush with the slats.

Tip: Before you fasten the slats to the frame, finish their edges and bottoms. Once installed, these surfaces are difficult, if not impossible, to reach.

Fasten the Top

To center the top between the legs,use shims

of equal thickness all around.Secure the top

to the frame with wooden fasteners (Photo

10 and Fig. A, Detail 2).These fasteners allow

the top to expand and contract by sliding

inside the slots in the aprons.

Apply the Finish

Finish the top and frame separately so you

can seal every surface. A wipe-on varnish is

a good choice. Follow the instructions

on the can, and put on three or four

coats. After the first coat, it’s a good

idea to sand the surface with 220-grit

sandpaper.

If you prefer a food-safe finish on the

top, use Behlen’s Salad Bowl Finish or

Behlen's Preserve Oil (see

Source, below). Do not use vegetable

oil because it will turn rancid.

Source

(Note: Source information may have changed since the original publication date.)

Woodworker’s Supply, 800-645-9292,

Side-Grain Tapered Plugs, 3/8-in. dia., #800-031 Oak, #800-039 Maple, $14.59 for 100 plugs, #800-035 Walnut, $18.39 for 100 plugs;

Freud 50-110 Top-Bearing Flush-Trim Bit, #129-626, $46.99;

Behlen’s Salad Bowl Finish

#133-008, 1 qt., $22.59; Behlen's Preserve Oil,

#801-462, 8 oz. squeeze bottle, $13.49.

Cutting List

Fig. A: Exploded View

Detail 1: Apron and Rail Joints

Detail 2: Slots and Top Fasteners

Fig. B: Jig for Routing

the Arched Rails

This story originally appeared in American Woodworker June 2001, Issue #87.

|

|

Click on any image to view a larger version

1. Keep your router stable

while plunging the mortises by ganging

two legs together.Make several shallow

passes until you reach full depth.To

maximize the gluing surfaces, the

mortises meet inside the leg and the

tenons are mitered to fit (Fig.A).

2. Cut tenons on the aprons and

rails with a dado set and the miter gauge.

Make a first pass on both sides as shown,

then make the final pass using the rip fence

to establish the tenon length. Hold the

apron tight against the miter gauge and flat

on the table. Fine-tune the tenon thickness

by adjusting the blade height. Note: Using the rip fence and miter gauge simultaneously is safe only

when there will be no off-cut piece.The blade guard must be removed for

this cut. Be careful.

3. Cut shoulders on the ends of

the tenon after adjusting the height of

the blade. Hold the apron on its edge,

tight against the miter gauge and make

two passes, as in Photo 2. Keep the

tenon slightly away from the fence on

the final pass and pare away the

remaining waste with a chisel. Note: Using the rip fence and miter gauge simultaneously is safe only when there will be no off-cut piece.The blade guard must be removed for this cut. Be careful.

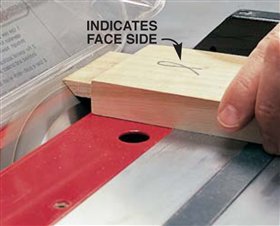

4. Miter the tenons, making sure

the angled edges are oriented properly

with the face side of the apron.

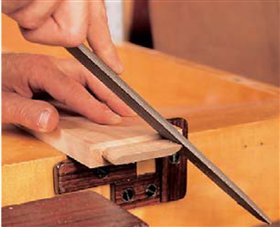

5. Round the shoulders of the

tenons with a rasp, making firm forward

strokes, so they’ll fit the mortises.

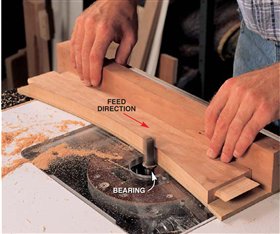

6. Rout the curved rails with a jig (Fig. B) and a flush-trim bit with a

top-mounted bearing (see Sources page 80). First rough-saw the curve on the

rail, leaving it about 1/8-in. oversize.Then mount the rail on the jig, using

double-faced tape.As you rout, the bit’s bearing rides on the jig’s curved edge.

Do half the curve, flip the rail over, and do the other half (see OOPS!, below). Note: The guard has been removed for photo clarity. Use yours!

Oops!

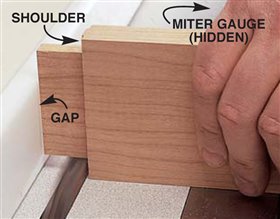

7. Before sawing the notches,

clamp a spacer block to the rip fence,well

in front of the blade. Screw a tall fence to

the miter gauge, leaving a gap so it won’t

bind against the spacer. Set the fence to the

combined widths of the notch and spacer,

minus the saw kerf. Raise the blade to the

height of the notch.

8. Cut notches after sliding the top

against the spacer block and clamping it firmly

to the tall fence.The spacer ensures an

adequate gap between the top and the rip fence

to keep the off-cut waste pieces from binding. Note: The blade guard must be removed for this cut. Be careful.

9. Attach the slats, using shims to keep them evenly spaced. Be sure to

put one shim between each leg and the adjacent slat. Use a clamp to keep the

slats aligned while the pilot holes are drilled and the screws are set.Wooden

plugs, glued in the screw holes and sanded smooth, create a finished look.

10. Cut wooden fasteners for the top from straight-grained stock

with evenly spaced dadoes sawn across its length. Black tape on the fence

indicates the correct length.

|