We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

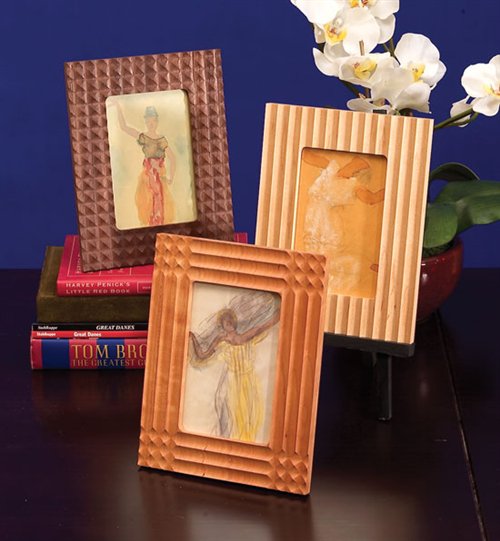

Fab Frames

No miters and no fuss! Multiples and cool variations are easy.

by Tim Johnson

Forget about cutting and fitting miter joints the next time you make

a picture frame. Scrap wood, a saber saw, a fence-equipped router table

and three common router bits are all you need to make this one.

The process couldn’t be simpler: Saw and rout an opening for a 4 x

6-in. image in the center of a board; then rout flutes around the face

(Fig. A, below). This procedure is ideal for making multiple frames, and changing the pattern is so

easy that you can rout several different-looking frames at the same

time (see “Amazing Variations,” below)

Those large offcuts you’ve been saving are perfect for this project,

but you can also make frame blanks by gluing up narrow stock. Hardwoods

such as birch, maple, cherry, beech, walnut and poplar are good choices.

|

Shape the Blank

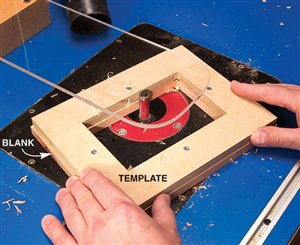

1. Glue together a template sized precisely, as shown in Fig. B

2. Plane wood for the blank to 1/2-in. thickness. This piece must be

3. Cut the frame blank to size, 1/8 in. wider and longer than your template.

4. Center the template on the blank and attach it with one screw.

5. After you’ve removed the template, drill access holes for the

6. Remount the template using all four screws.

7. Using a flush-trim bit (see Sources, below), rout the blank to

8. Complete the picture opening by installing a rabbeting bit and

Rout the Flutes

I’ll explain how to rout the basic frame, but you can use the same steps to create several variations.

The frame’s 1/2-in.-wide flutes are routed with a 3/4-in.-dia.

9. Raise the bit to set the flute’s width (Photo 2). The flutes

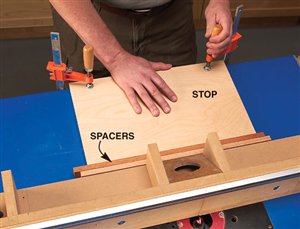

10. Lock the fence in position to rout the outside flutes (Photo 3).

11. Mill a pair of long spacers exactly 1/2 in. wide and install

12. Rout the outside flutes all around the frame blank (Photo 5). A

13. Loosen the fence and remove one spacer. Firmly push the fence

14. To rout the inner flutes, simply remove the remaining spacer and reposition the fence against the stop.

Finishing Touches

15. Trim the frame’s sides on the tablesaw (Photo 6).

16. Sand the flutes to eliminate ridges and blend uneven spacing.

17. To make a stand for the frame, saw a 12-degree bevel on one edge of a long blank. Then cut the stand to size.

18. Glue the stand to the back of the frame. You don’t have to use

19. Apply your favorite finish to both sides of the frame. I prefer

20. Install the glass, matte board, image and the back. Then screw

|

Photo 1: This picture frame is just a piece of wood with a

|

Sources

(This information may have changed since the original publication date.)

Freud Inc., www.freudtools.com, (800) 334-4107

1/2-in.-dia. flush-trim bit with three cutting flutes, #44-104, $20; Rabbeting bit with bearing, #32-102, $26. 3/4-in.-dia. round-nose bit, #18-112, $26.

Rockler, www.rockler.com , (800) 279-4441

7/8-in. brass-plated turn buttons, #27912, $2 for a pack of eight.

Klingspor’s Woodworking Shop, www.woodworkingshop.com , (800) 228-0000

Tadpole contour sanders, convex set, #KL20000, $5.

Albin Products Inc., www.albinproducts.com , (800) 225-6821

EaselMate frame stand, pack of two, $6; pack of six, $16; pack of 12, $30.

This story originally appeared in American Woodworker October 2006, issue #124.

|

|

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.