|

One of the best buys you can

make for your tablemounted

router is a set of

stile and rail cutters. These cutters

allow you to join frame pieces

together at right angles by making

a decorative version of the tongue

and groove joint. It’s sometimes

called a “cope and stick” joint

because the rail is coped to fit

around the profile that’s “stuck”

onto the stile. When assembled,

two stiles and two rails form a

frame with a groove around its

inside edge, perfect for holding a

panel.

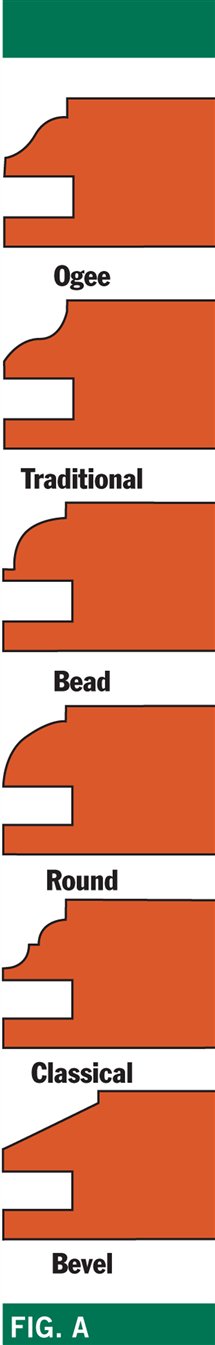

Stile and rail cutters come in a

variety of profiles (Fig. A) and are

great for making kitchen cabinet

doors and other frame and panel

structures. Most manufacturers

offer them either as dedicated two bit

sets or as a single “reversible”

bit. With the two-bit set you get

one bit to make a “profile” cut on

long grain (the stile cutter) and

another to make a matching

“coped” cut on the end-grain (the

rail cutter). With the single,

reversible-bit sets you get removable

parts that can be configured to

make both cuts (photos at right).

Dedicated sets are best in production shops, but reversible sets are

a good choice for anyone working with a budget because they’re

cheaper to buy and still offer great performance. Using the reversible set

is a piece of cake (Photos 1 – 6), as long as you remember to make

the cope cuts face-side up and profile cuts face-side down. Making

the changeover from profile to cope cutting (or back) takes only a few

minutes. You’ll be impressed with the quality of the fit and the

speed with which you can make a quantity of doors or frames.

Sources

(Note: Product availability and costs are subject to change since original publication date.)

Reversible cutters and toggle clamps available at:

Eagle America, eagle-america.com, 800-872-2511.

Highland Hardware, highland-hardware.com

800-241-6748.

MLCS, mlcswoodworking.com,

800-533-9298.

Sears, sears.comcraftsman, 800-377-7414.

Sommerfeld’s, sommerfeldtools.com, 888-228-9268.

Woodcraft, woodcraft.com,

800-225-1153.

The Woodworker’s Choice, 1-800-twc-4tools.com, 800-892-4866.

Fig. A: Stile and rail

cutters come

in a variety of

decorative

profiles.

This story originally appeared in American Woodworker February 2000, issue #78.

|

|

Click any image to view a larger version.

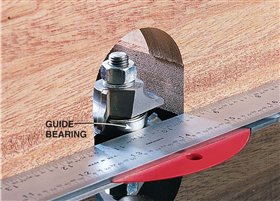

Reversible cutters have

removable profile- and slot-cutting wings

along with shims and a guide bearing mounted

on a single shaft. Changing from profile to cope

cutting (see photo above) means disassembling the

cutter, rearranging the wings and reassembling—a two minute

process. Depending on its orientation, the profile

cutter either makes the profile or its coped negative. Make

sure the flat sides of the carbide cutters face into the cut.

Shims are included to adjust the fit if it’s too loose.

Phase 1: Make Coped End-Grain Cuts

1. Set the fence flush with the bearing on the rail cutter, using a

straightedge to assure a smooth pass.

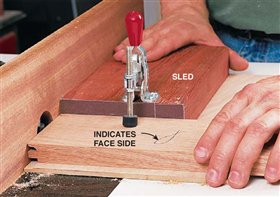

2. Make test end-grain cuts. You’ll need a sled to hold the

rail safely and ensure a square cut. Simply glue a block of wood with

one squarely cut end onto a larger piece of 1⁄4-in. plywood, aligned on one

edge.Then attach a toggle clamp.Clamp the rails in the sled face-side up

for all end-grain cuts.

3. Set the height of the cutter by making cuts

so the rabbet on the bottom of the rail is at least

3⁄16-in. deep. Otherwise the corresponding bottom

shoulder on the stile will be too thin and may break.

Once you’ve got the height set, use the sled and make

all of the coped end-grain cuts in the rails.

Phase 2: Cut Profiles on Long Grain

4. Disassemble the cutter to rearrange the pieces for

making profile cuts. Leave it mounted in the router when loosening

the locking nut—it’s a handy way to hold onto the shaft. After

rearranging, don’t over-tighten the nut or you’ll damage the shims.

5. Set the height of the stile cutter by aligning its slot-cutting

wing with the tongue on one of the rails.These cuts don’t require

a sled. Use scrap stock to make a test cut, check its fit with the rails and

make adjustments, if necessary.

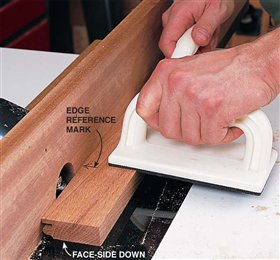

6. Make profile cuts on the stiles and inside

edges of the rails with the stile cutter. (Yes, use the

stile cutter for this profile cut on the rails!) Orient the

pieces face-side down and mark the edge to be

routed. Use push blocks to hold the stile against the

fence and the table when you guide it past the bit.

|