We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Master Your Brad Nailer

5 tips and products to make your brad nailer safe and easy to use.

A brad that unexpectedly shoots out the side of your project is guaranteed to make you curse, especially if your finger happens to be in the way. Blowout is instantaneous and dangerous. 18-gauge brads are so darn thin, they have a tendency to deflect whenever they encounter something hard, like a knot. In most cases, blowout is caused by the wood’s uneven cellular structure, so you can take steps to limit its occurrence.

Avoid the blowout curse

• Orient the brad correctly. If you’re attaching a face frame, hold your nailer so its handle is perpendicular to the outside edge (not parallel, as shown in the photo). This positions the brad’s wedge-shaped tip so any side-to-side deflection will be contained in the wood.

• Fire into the face frame’s growth rings. Check the end grain. If your firing angle parallels the growth rings, the brad will simply deflect off the hard latewood.

• Increase the air pressure when you nail into hard wood. Just like a putt that falls off line when it loses speed, a brad driven softly is more likely to deflect.

• Protect yourself. Even when you take preventative safety precautions, blowout can still occur. Always wear eye protection and keep your fingers well away from the brad’s path.

Avoid nailer elbow

A stiff, unwieldy air hose makes your nailer hard to maneuver, especially in tight spots. This swiveling air plug ($9 for 1/4-in. hose; $10 for 3/8-in. hose) increases your range of movement by acting as a stress-relieving universal joint between your nailer and hose (see Sources).

18-gauge brads are interchangeable

Argh! You’re all out of brads. The owner’s manual says “USE OUR BRADS ONLY!,” but the store doesn’t carry the right brand for your nailer. What to do? If you’re in this pickle, don’t worry about the brand. The shafts of all 18-gauge brads are essentially the same size. Just make sure the brads you buy are the right length.

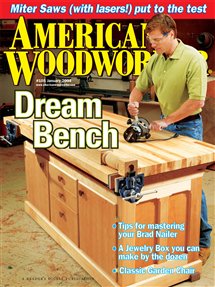

Most owner’s manuals list the lengths that’ll fit, but here’s how to be sure: On the side of your nailer’s magazine is a series of flutes that correspond to the different brad lengths it accepts. To fit, the brad clip must sit on the steel wear strip at the bottom of the magazine and the brad heads have to rest between the flutes. Brad strips that hang from the flutes without bottoming on the wear strip don’t fit. They’ll cause misfires, jams and/or premature wear.

Don’t hammer your nailer

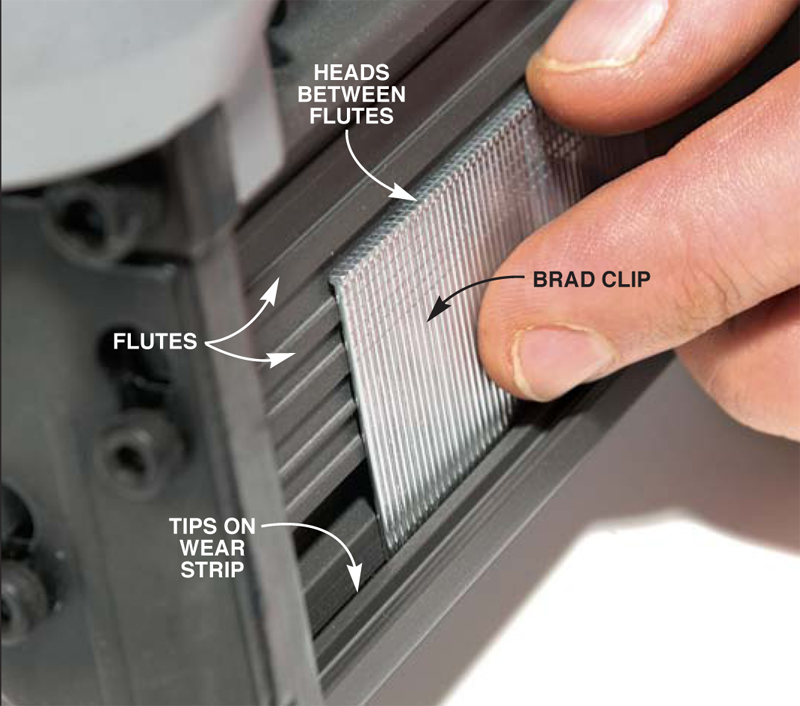

High air pressure is hard on your nailer. It’ll wear out the O-rings and other internal components prematurely. Even though brad nailers are often rated to handle pressure up to 125 pounds per square inch (psi), they’ll work just fine at 90 psi or less, and they’ll last a lot longer. Adjust the air pressure (within the range specified in the owner’s manual) according to the hardness of the material and the length of the brad. Operate at the lowest pressure that’ll consistently drive the brads you’re using.

Ditch that old hose

Nothing’s worse than being tethered to a cumbersome air hose. It adds dead weight that makes your nailer hard to maneuver and tiring to use. Reinforced polyurethane hose is tougher and more durable than old-fashioned rubber hose. It’s also thinner, more flexible, and weighs less than half as much. When it’s attached to your nailer, you’ll hardly know it’s there. The 1/4-in. inside diameter supplies plenty of air for brad nailers, as well as most other pneumatic tools. A 25-ft. length costs about $36 (see Sources).

Sources

Carlson Systems, Inc., csystems.com, 800-325-8343, 1/4″ ball swivel air plug, 948600, $9; 3/8″ ball swivel air plug, 948624, $10.

Coilhose Pneumatics, coilhose.com, 732-390-8480, Flexeel reinforced polyurethane straight hose, PRE14-25, 1/4″ i.d., 25′ length, $36.

This story originally appeared in American Woodworker January 2004, issue #105.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.