We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

12 Tips for Better Sharpening

Get better results in

less time with these

great tips.

By Ed Krause

Hand tools are a joy to use, but only when they’re sharp. Just as

learning to walk is the prerequisite to running, successful sharpening

is the key to “unplugged”woodworking.Try these tips and

you’ll be surprised at the strides your sharpening skills take and by

the quiet satisfaction you get from your hand tools.

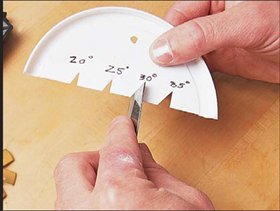

Homemade Angle Checker

This angle checker, made from a plastic lid, is a simple

(and free) way to check the bevel on your chisels and

planes. It only takes a few minutes to make.

Simply cut a 4- to 6-in. diameter plastic lid in half.

Then, using a protractor,mark the desired angles on a

piece of paper. Cut out the triangles and use them as a

template to mark the angles on the lid.Cut out the angles

on the lid with a pair of scissors.Drill a hole at the top and

hang it on the wall near your grinder. |

|

Click any image to view a larger version.

|

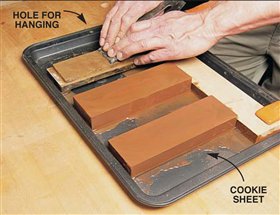

No More Waterstone Mess

There’s no getting around it—waterstones are messy.

Here’s a simple tip for keeping that mess contained: Pick

up a heavy-gauge, 13 in.by 19-in. cookie sheet (about $7)

at the grocery store, hardware store—wherever. It’s large

enough to easily hold three stones. Use a 3/4-in. board

pushed against the stones and clamp down the board and

the cookie sheet on your bench.When you’re done, just

wipe the cookie sheet dry and hang it on the wall. |

|

|

Dress for Success

Ever lose your temper? I mean your chisel’s temper.Don’t

get burned by a clogged, uneven grinding wheel.Dressing

your grinder wheels periodically to keep them clean

and flat helps prevent the excess heat that leads to bluing

and loss of temper(s).

Single-point diamond wheel dressers do a great job but

they’re difficult to use freehand. Try a flat-tip diamond

dresser instead. It has 36-grit diamond stone particles

imbedded in a 1/2-in.wide by 3/4-in.-long face. Simply

place it on your grinder’s tool rest and make contact with

the wheel. |

|

|

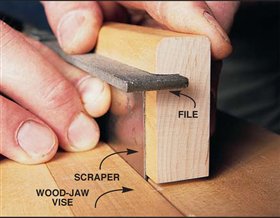

Surefire Scraper Filing

You’ve probably heard other woodworkers talk about what

a great tool the scraper is, but maybe you’ve never had

much luck with one yourself.Using them is easy; getting a

good edge on them is the tough part. The hardest step in

sharpening a scraper is the first one—filing the edge square

and flat. Start off right with this easy-to-make file holder:

Cut a kerf equal to the thickness of an 8-in.mill file in

a 1-1/4-in. thick by 4-in. wide by 6-in.-long piece of

wood.The kerf should be a little deeper than half the width

of the file.This allows you to set the file at different depths

to avoid dulling it in one spot. Clamp the scraper in a

wood-jaw vise.Push the scraper firmly against the holder

while filing for a perfectly square edge. |

|

|

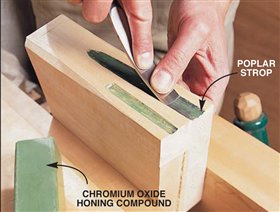

Custom Gouge Strop

Getting a mirror finish on the contoured profiles of

carving gouges can be a real hassle. The curved surfaces

don’t lend themselves to polishing on a flat stone or

strop.Making a custom strop is easy.Use the chisel to cut

its own contour in a piece of poplar or basswood. Rub

chromium oxide polishing compound in the contour and

you have a custom-made strop. |

|

|

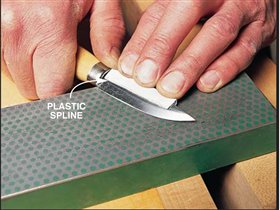

Easy Knife Sharpening

Don’t keep your sharpening skills confined to your shop

tools. Why not tackle that dull set of kitchen knives

you’ve been crushing tomatoes with? Here’s a great tip:

Go to any office supply store and buy one of those looseleaf

folders with a plastic spline (about 40 cents).Cut and

trim the spline to fit over the back of the knife. The

spline raises the back of the knife just enough to put a

consistent bevel on the cutting edge.Now your knives will

glide right through those tomatoes! |

|

|

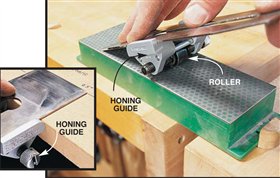

Spend Less Time Sharpening

Less time sharpening means more time woodworking. Isn’t

that what we all want? Honing guides get the job done fast,

but setting the blade in the guide to get the right bevel angle

can be time consuming.

Here’s a quick trick:Mark the appropriate blade extension

for each bevel angle on your benchtop,or a wood scrap,

for convenient reference. Hold the edge of the blade to

the desired bevel mark, butt the guide to the edge of the

bench and tighten. The side-clamp honing guide, shown

above, automatically squares the blade and prevents it

from rocking or shifting in the jig. |

|

|

The Right Angle Every Time

Chisels and planes have bevel angles from 25 to 35

degrees depending on their intended use.You can buy a

jig for grinding these angles, or make your own angle

blocks at no cost!

Make one block for each angle. Glue up a block

2-1/2 in.deep by 4-in.wide by 10-in. tall.Mark the desired

angle on the top of one side.Drill a 1-in.hole through the

side of the block at the halfway point of your angle mark.

Then cut the angle on your tablesaw. The remaining

groove makes an excellent guide for your fingers.Cut the

block to length so the top is equal to the center height of

your wheel.To secure the block, drill a 1-1/4-in.hole near

the bottom of the block for a bar clamp. |

|

|

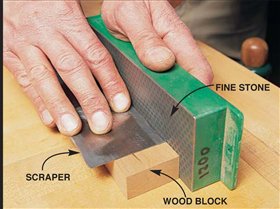

Fine Edge On Your Scraper

The edge left after filing a scraper is a little rough for fine

work. Use a piece of wood to align the scraper when

moving it against the stone and you’ll retain the square

edge you achieved with your file jig.

An extra-fine (1,200) diamond stone is a good choice

for this because the scraper won’t wear a groove in the

stone. |

|

|

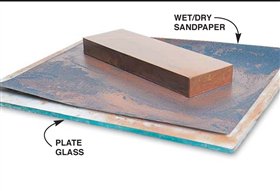

Keeping Waterstones Dead Flat

Waterstones are great for sharpening bench tools, but their soft

binder makes them prone to dishing out and grooving. Fortunately,

flattening them is no big deal.An 11 in. by 12-in.piece of

1/4-in.plate glass and a sheet of 180-grit wet/dry sandpaper provide

a cheap, perfectly flat abrasive surface for flattening all

your waterstones.The glass will cost you about six bucks (be sure

to have the edges sanded) and the wet/dry sandpaper about 70

cents a sheet.Both are available at hardware stores.Use water to

hold the paper on the glass and to flush away the slurry. |

|

|

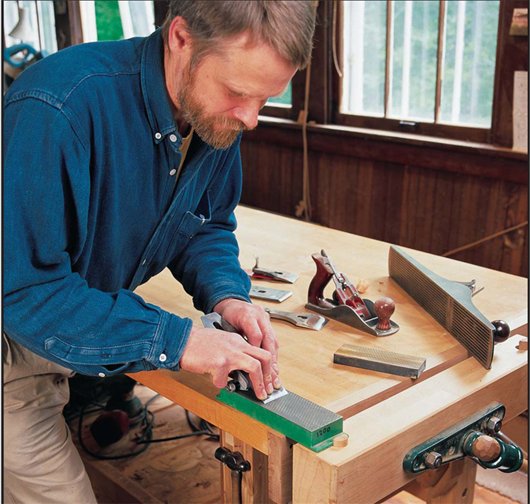

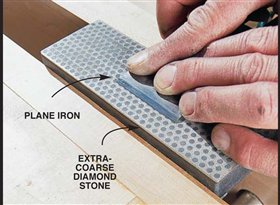

Flatten Blade Backs Fast

It would be great if chisels and planes came from the factory

ready to use, but they don’t. A perfectly flat,mirrorlike

finish on the back is essential for a truly sharp edge.

Flattening always requires a large dose of elbow grease and

patience. The fastest method is to use an extra-coarse

diamond stone. It won’t dish out the way oilstones and

waterstones do and it can easily be clamped in a vise.

Once you have a flat surface, move on to finer stones

until your chisels and planes shine like a mirror. |

|

|

3 Ways to Test for Sharpness

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.