We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Foolproof Tenons

Two blades and

a rock-solid jig guarantee success.

By Tom Caspar

Mortise and tenon joinery is the

heart of many classic furniture

projects. It’s an incredibly strong,

time-tested method of connecting

boards. Making these precisely fit

joints can be fussy and demanding

work. But it doesn’t have to be.

There are at least a dozen ways

to cut tenons.We’ve chosen a

technique that delivers the goods

every time, whether you’re a

beginner or seasoned pro. It’s

simple, safe and economical. Best

of all, this technique will save you

a lot of set-up time. Rather than

fit tenons by trial and error for

each project, you can easily

reproduce the same size tenons,

time after time.

What you’ll need:

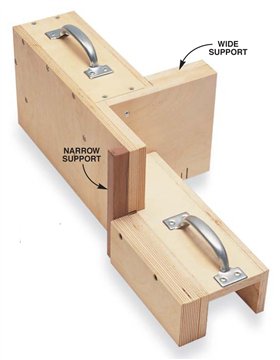

A Tenoning Jig

You can buy a commercial jig or make a better one

yourself. Looking for a better mousetrap, we

designed a heavy-duty jig that slides on top of a

tablesaw fence. (Your fence must have parallel

sides for this jig to work, however. If you have an

L-shaped fence, see the jig in AW #81, page 55.)

Features:

– Large capacity.The 8-in.-tall sides are high

enough to support a rail up to 36-in. long.

– Dedicated sides. No commercial jig offers this

handy feature. The left side supports the edge of a

rail; the right side supports the face.

– No tear-out. None.A backer board prevents annoying

tear-out when you rip the tenon cheeks. It’s easy to replace

the backer board when you change settings.

– Safe operation. Generous handles keep your hands out of

harm’s way.An oversize block behind the backer board covers

the saw blade after it makes the cut. |

|

Click on any image to view a larger version.

|

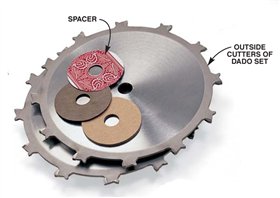

Two Saw Blades

Make smooth-sided tenons with a

pair of matched sawblades

separated by spacers.You can

use the outside cutters of a

dado set or two carbide-tipped

7-1/4-in. circular saw blades

(about $8 each). |

|

|

A Zero-Clearance

Insert with Splitters

Make a dedicated insert for your

tablesaw so your tenon cutting is as

safe as possible.Although the parts

you cut will be clamped to the jig,

this insert provides additional

support from underneath. |

|

|

Build the Jig

Our jig rides on top of your tablesaw and is guided by the

fence.The fit between the sides of the jig and the fence has

to be just right. If it’s too tight, you’ll have to push too hard.

If it’s too loose, your tenons won’t be straight.Here are some

tips to make building and fitting the jig easier:

– Drill all the 13/64-in.-dia. clearance holes in the jig with

a drill press (Detail 1, below).

– Creep up on the width of boards C, D, and E. For your

jig to slide properly, the right fit is a matter of 64ths of an inch.Rip the boards slightly oversize, then clamp them

between the faces of the jig and try sliding the jig along

your saw’s fence.

– If your jig is too tight, shim the edges of boards C, D and

E with masking tape. Don’t laugh! It’s an effective way to

fine-tune the fit.

– Clamp the jig together and make sure it’s square to the

top of the tablesaw before drilling any pilot holes and

driving in the screws. Don’t glue the jig together.You may

need to disassemble it later to adjust the fit. |

|

Cut the corners of the jig on the tablesaw (Detail 2).

Stop the cut at the pencil line and withdraw the board.

The bottom side of the board may be overcut, but

that’s OK. It’s only a jig! |

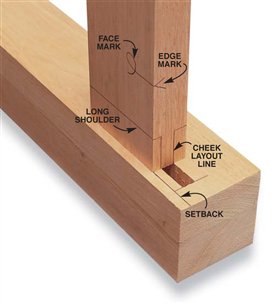

Getting Started

Mill all your stock straight and square, and boldly mark the face and edge of each piece.

Usually the face side is the outside of a rail and the reference edge is the top of a rail.

1. Make the mortises first. It doesn’t matter

whether you use a mortising machine, a router or a

drill press. It’s far easier to fit a tenon into a mortise

than it is to customize a mortise to fit a tenon. |

|

|

2. Lay out the

tenon’s cheeks

directly from the

mortise.This joint

won’t be flush, so first

you must draw a line representing the setback

of the rail from the front of a leg or a stile.

Draw lines across the face and edge of the rail

representing the shoulders of the tenon so you

can set the height of the cut on the tablesaw. |

|

|

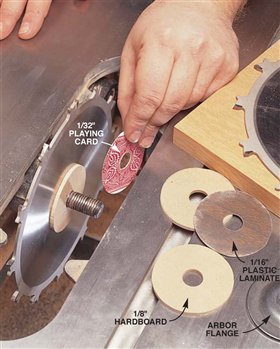

3. Install homemade spacers

between the saw blades.You’ll need

three different kinds of spacers to fit

every size tenon (approximately

1/8 in., 1/16 in. and 1/32 in. thick). Make

them the same diameter as the flange

on your saw’s arbor.The best way to

figure out the right mix of spacers is

by trial and error, making tenons in

scrap wood. Fortunately, if you save

and label the spacers you should only

have to go through this process once. |

|

|

Cut the Cheeks

One pass through your ganged-up saw blades and you’ve cut both sides of the tenon.

4. Raise the blades to

match the shoulder

line on your rail. |

|

|

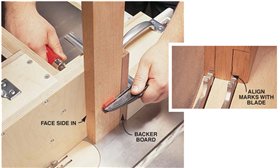

5. Clamp the rail to the tenoning jig,

face side in, and adjust the tablesaw’s

fence so the layout marks line up with

the two saw blades. |

|

|

6. Rip the cheeks. Slide the jig through the cut,

then pull the jig back and unclamp the rail. Rip all

your tenons. Make sure the marked face of each of

your rails is the face you clamp against the jig.

When you’re done, remove the double blades

from the tablesaw and install a crosscut saw blade. |

|

|

Cut the Long Shoulders

Make perfect, tight-fitting shoulders with a crosscut saw blade.

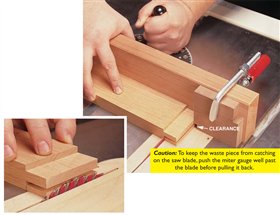

7. Cut the long shoulders.

Set up your miter gauge

with a fence, and clamp a

stop block to it. Raise the

stop block above the waste

piece so the waste won’t

get trapped.

Cut all the shoulders on

the face sides of the rails

first.Then readjust the

height of the blade, if

necessary, to cut all the

shoulders on the back sides

of the rails.

Raise the blade

so it barely touches

the cheek. |

|

|

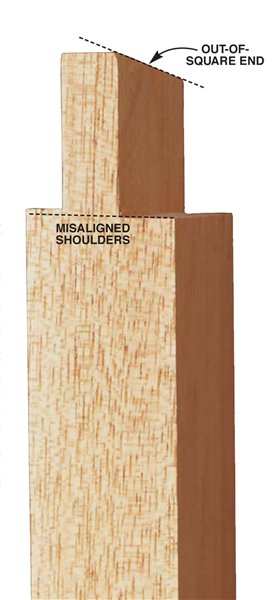

Oops!

My shoulders are drooping!

I thought they were going to

line up just right but somehow

they became offset. I checked

the ends of the rail with an

accurate square, and wouldn’t

you know it, they were off.The

culprit is my miter gauge. It

wobbles in the slot, so I don’t

get an accurate 90-degree cut

every time.And if the shoulder

cuts (Photo 7) aren’t exactly

square, the shoulders won’t

line up at the edges.

The fix? I bought a premium

miter gauge ($100 to $170) that fits

tighter in the slot. Rather than

toss out the rails, I re-cut both

ends as little as possible and

re-cut the shoulders.Now my

project is a bit smaller than

originally planned, but the

joints are perfect. |

|

|

Cut the Tenon’s Width

Make two rip cuts on the right side of the tenoning jig.

They establish the tenon width.

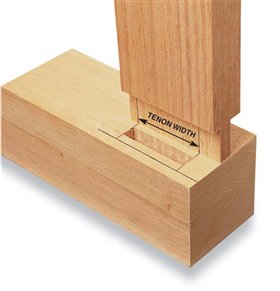

8. Mark the width of

the tenon directly

from the mortise. |

|

|

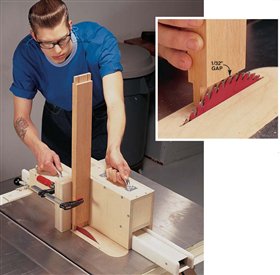

9. Rip the tenon to width. First,

move the fence to the left side of

the saw blade. Clamp the rail to

the right side of the tenoning jig

and adjust the fence until the

blade lines up with the marks.

Raise the

blade about

1/32-in. lower

than the

shoulder to

avoid cutting

into it. |

|

|

Cut the Short Shoulders

Sawing all four shoulders flush isn’t realistic. Don’t push your luck! Finish them with a sharp chisel.

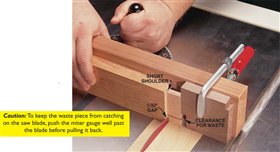

10. Rough cut the waste

pieces on the tablesaw.

Position the stop block so

the short shoulders are

proud by 1/32-in. or so.

In theory, it’s possible to

make this cut precisely

flush, but in practice it’s

darned hard. Don’t risk

messing up your crisp

shoulders! |

|

|

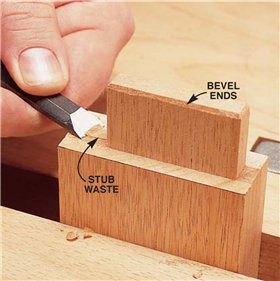

11. Remove the stub waste

with a chisel.This paring

requires a keen edge, but if

you cut too deep, it won’t

show. Bevel the ends of the

tenon with a file so it will

easily fit in the mortise. |

|

|

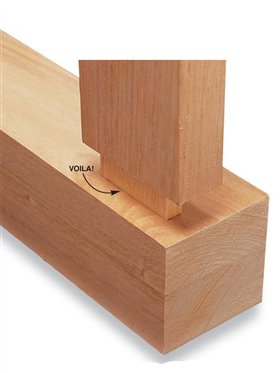

12. Test the fit. If your tenon

is too wide to fit into the

mortise, it’s easy to go back

and trim off one side with

the tenoning jig. If it’s too

loose, glue the waste pieces

back on and cut again. |

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.