Basic HVLP Spray Techniques

How to succeed at spraying a waterborne finish.

By Jon Stumbras

| When it comes to finishing, we’re all looking for easy answers that give professional results. Years ago, I switched from brushed and wiped-on finishes to shooting waterborne finishes with a high volume, low pressure (HVLP) turbine sprayer, and I’ve never looked back. Now my finishes are quick, safe and durable, and they look like a thousand bucks.

I made a lot of mistakes along the way, however. Spraying is a whole craft in itself, and I had to learn on my own, the hard way. If you’ve never sprayed before, or are just learning how, this step-by-step guide will help you avoid the most common pitfalls. We’ll cover how to set up your shop, how to adjust the spray gun and how to go about spraying a basic cabinet. Obviously there are a lot of fine points that we won’t cover, but this is really all you need to get going.

A good HVLP system can cost $600 or more, but if you want to take a test drive before buying, or simply want to get one big project done quickly, you can rent an HVLP system at a paint store.

Waterborne finishes are user-friendly

Waterborne finishes are clearly the best choice for spraying in a home shop.You get most

of the benefits of sprayed lacquer or polyurethane without needing an explosionproof

exhaust fan or explosion-proof lights.Waterborne finishes generally dry to the

touch in 3 to 10 minutes, and you can re-coat in less than an hour, building up 3 or 4

coats in a day. The quicker a finish dries, the less likely dust will contaminate the surface.

Clean-up simply requires warm water.

Be sure to buy a waterborne finish that is labeled for spraying. Waterborne finishes for brushing are too thick to successfully spray, and generally can’t be thinned. |

|

Click any image to view a larger version.

|

Before You Start

Before spraying, do some housekeeping in your shop and practice how to hold the spray gun.

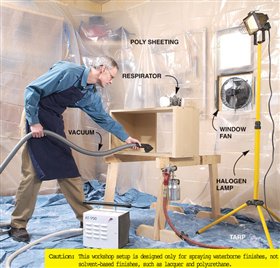

Prepare Your Shop

Spraying in a small shop is a constant battle

with dust and overspray. (Overspray is the

fine mist that bounces off or misses your

project.) Outfit your shop with plastic

sheeting on the walls, a canvas tarp on the

floor, a halogen light and a window fan (about

$150 total). Dust kicked up by the gun can

ruin a finish.The tarp and sheeting eliminate

the dust hazard and keep overspray from

settling on your tools, floor and walls.Vacuum

your project before you spray.

Ventilate your shop with a window fan

behind the project, blowing to the outside.

Crack open a door or window on the other

side of the shop to supply fresh air.Wear a

respirator with an organic vapor cartridge

when you spray waterborne finishes. |

|

|

Strain the Finish

Waterborne finishes may contain solid clumps that will clog the gun or spoil a finish. Solid pieces of finish or dust may fall into the finish can, too. When you pour finish into the sprayer’s cup, strain it through a small nylon anklet sock. You can rinse the nylon with water and use it over and over.

For the steps ahead you’ll need a large disposable surface to practice on. We used builder’s rosin paper, available at a home center for about $14 a roll, but plain brown paper or cardboard would work. |

|

|

Practice Holding the Gun

There’s a right way and a wrong way to hold the gun, and you must be familiar with the right way before adjusting the gun’s controls.

The first step is to turn on the HVLP turbine to pressurize the cup. Pressure keeps finish from traveling back up the pressure tube and dribbling out of the gun.

Pick up the gun and hold it at 90 degrees to the surface. Don’t let the gun droop, particularly when you adjust the gun’s controls in the steps ahead, because that will create an uneven spray pattern. Hold the gun 6 to 8 in. away from the surface.

Lock your wrist and move the gun back and forth with your arm. The speed of your arm movement determines how much finish you apply. Move too slow and the finish will pool. Move too fast and the coat will be too thin. You’ll figure out the right speed after you set the gun’s controls. |

|

|

Adjust the Gun

Setting the controls on the gun can be a complicated process of trial and error, but there is an easier way. We’ll take you through an order process that will work each time you readjust the gun for different situations.

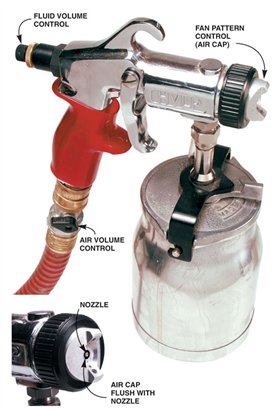

Know the Gun’s Controls

Every HVLP system has three basic controls: the volume of air flow, the volume of fluid flow and the type and size of the fan pattern. These controls may be located in different places than on the gun shown at right. If you’re in doubt, check the owner’s manual.

An HVLP gun uses air to break up a fluid finish into tiny droplets. It’s called “atomization.” Once atomized, the droplets are formed into an adjustable spray pattern, called the “fan.” The trick to adjusting the gun is to get the right atomization, or balance of air and fluid volume, across the entire width of the fan pattern. But before you tackle that problem, the first control to adjust is the fan pattern itself.

Set the Air Cap for Fan Size

A small detour here. If you have the type of gun that has an adjustable air cap, set it now. Turn the cap so the nozzle is flush with the face of the air cap. As you become better at spraying, you can readjust the air cap to change the size of the fan pattern. For now, leave the nozzle flush with the air cap. |

|

|

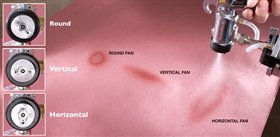

Select the Fan Pattern

All air caps can be set in three positions. Each position creates a different fan pattern. For learning how to set the air and fluid volume controls in the steps ahead, set the air cap to make a vertical pattern. Air and fluid volume settings are about the same for vertical and horizontal fans. Round fans require readjusting these settings.

A vertical fan is good for tops, or any time you move the gun side to side. A horizontal fan is good for sides, or any time you move the gun in and out, directly away from you. A round fan is used in special situations to concentrate the finish in a small area. |

|

|

Adjust the Air Volume

| Regulate the air flow from the turbine by turning the knob on the air hose. Make this adjustment before tackling the fluid volume, below. Increasing the air flow creates tinier droplets of finish, or more atomization. Thick finishes need more air; thin finishes need less air. Hold the gun 6 in. from the surface and pull the trigger back only far enough to create a 6-in.-wide fan pattern. |

|

|

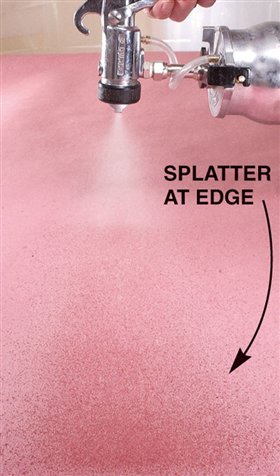

Too Little:

To start out, turn down the air control most of the way. Pull the trigger and make a pass. If finish spits out of the gun or if you see splatter at the edge of the fan pattern, turn up the air a little bit. |

|

|

Just Right:

Slowly increase the air volume until the fan is evenly atomized and has clearly defined edges, without splatter. |

|

|

Too Much:

If you turn up the air volume too much, you’ll get spray that looks like a fine mist, plus an excessive amount of overspray. Reduce the air volume and test again. (If the air volume is at the maximum and the gun is still spitting finish, use a thinner finish.) |

|

|

Adjust the Fluid Volume

| Regulate the fluid volume by turning the knurled knob at the back of the gun. This knob controls how far you can pull the trigger. As you pull the trigger, the volume of finish increases and so does the size of the fan pattern. Your goal is to set the trigger so it automatically stops at the ideal size fan for the work you’re doing. To start out, stop the trigger at a 6-in.-wide fan. |

|

|

Too Little:

Begin by adjusting the trigger for a minimal pull. As you move the gun, the fan should be smaller than 6-in. wide. Some spraying situations, such as spraying a narrow face frame, call for a small fan in order to minimize overspray. |

|

|

Just Right:

Increase the fluid volume until the fan is 6-in. wide. Turn the knob to stop the trigger at this point. Now you can simply pull the trigger all the way back, like an on/off switch, to spray the same size fan. As you move the gun, you should get an even, wet coat of finish, not a mist and not a flooded surface. |

|

|

Too Much:

Back off the fluid volume if your surface is flooded with finish, or move the gun at a faster rate. The fan will be too large when you pull the trigger back too far. |

|

|

Spraying Techniques

Practice makes perfect. Rather than start right in on an actual project build a disposable cabinet to try out the following techniques.

Spraying Inside a Cabinet

Always begin with the inside of a cabinet. A general rule of thumb of spraying is to start with the least visible surface and end with the most visible surface. This minimizes overspray from settling on and spoiling a surface that really counts. Overspray on visible areas will be covered by the final coat.

Fill your cup 3/4 full with finish. This prevents the fluid nozzle inside the cup from being starved of finish when you tip the gun to get into corners.

Adjust the air cap to make a vertical fan. Increase the air flow to create a light spray pattern and minimize overspray. Light coats are fine inside a cabinet. Reduce the fluid volume to make a 6-in.-wide fan.

Next, follow the steps as shown:

| 1. Spray under the top, moving from the back to the front. The fan pattern should just reach the edge of the cabinet back. |

|

|

| 2. Spray the back, overlapping each pass by 50 percent. Position the edge of the fan pattern to just reach the inside corners. If you spray directly into the corner, finish will run down the inside edge or overspray will bounce back toward you.

On an actual cabinet, remove the back if you can and finish it separately. |

|

|

| 3. Spray the sides, moving from back to front, away from the overspray. |

|

|

| 4. Spray the bottom, tipping the gun as close to 90 degrees as you can to create an ideal fan pattern. This is the most visible part of the cabinet’s inside. Spraying here last blends in overspray from previous steps. |

|

|

Spraying Face Frames and Small Surfaces

1. Switch the air cap to a horizontal fan pattern. Reduce the size of the fan pattern to about 3-in. across to minimize overspray. You can reduce the fan by reducing fluid volume, reducing the air and fluid settings together, or moving the gun slightly closer to the surface. Always test on paper before spraying your cabinet.

When you first pull the trigger to spray any vertical outside surface, such as this face frame, don’t aim right at it. Instead, aim the gun at a point above the face frame, as indicated by the yellow oval at left. Then pull the trigger and work your way down. Don’t release the trigger until you’re past the bottom. Do this in one fluid movement, always holding the gun perpendicular to the face frame.

|

|

|

Spraying Vertical Surfaces

Adjust the air cap for a horizontal fan pattern. Adjust the fluid volume and the air volume to make a 6-in. fan pattern on a piece of paper.

| 1. Start spraying at the top. Aim the gun at a point above the cabinet and pull the trigger. Then move down the cabinet, just as you did with the face frame above. |

|

|

| 2. Return at the bottom and work your way up, overlapping the first pass by 50 percent. Once again, use the same technique of aiming at a point underneath the cabinet when you first pull the trigger. Repeat an up and down sequence until the side is covered. |

|

|

Spraying Tops

Set up your light at a low angle to the top so you can clearly see your spray patterns.

The edge of a top deserves special attention. It gets three coats for every one coat that goes on the top itself, in part because edges inevitably get extra wear. In addition, it’s easy to sand too deep between coats on a narrow edge. Extra coats will help prevent accidentally cutting into a stain layer under the finish.

Set the air cap for a vertical 6-in. fan pattern for both the edges and the top surface. It’s not necessary to reset the air cap to a small fan for the edges, because that will slow you down.

Waterborne finishes dry very fast. Your goal is to keep the gun moving at all times. Each pass should blend into a previous pass while it’s still wet.

| 1. Spray all four edges, all the way around the top. Hold the gun at 90 degrees. Some overspray will land on the top, but that’s okay. You’ll cover it up later. |

|

|

| 2. Spray the top edges. Hold the gun at 45 degrees. Again, don’t worry about overspray onto the top. |

|

|

| 3. Spray the top. Hold the gun at 90 degrees, and spray across the front. Use the same technique of handling the gun’s trigger as you did with vertical surfaces, above. As you move the gun from side to side, pull the trigger before you reach the top and release the trigger only after you’ve passed beyond the top. |

|

|

| 4. Overlap each pass by 50 percent. Alternate direction back and forth to keep the gun moving quicker than the finish can dry. Spraying from front to back directs overspray toward the window fan. Stop spraying when you reach the back. |

|

|

Spraying Raised-Panel Doors

Edges are everywhere on a raised-panel door! The secret to success is to follow a systematic plan.

To set up the gun, turn the air cap to a vertical fan pattern. Then increase the air flow a bit beyond where you set it in “Adjust the Air and Fluid Volume,” above. This increases the atomization of the finish, producing a finer spray and lighter coat. Finally, reduce the fluid volume (the trigger setting) to make a 4-in.-wide fan pattern. Now you’re set to go.

Place the door on some 2x4s to elevate it above the table. The best setup, though, is to make a turntable to support the door. Then you can rotate the door as you go, always spraying towards the window fan.

| 1. Spray all four edges, all the way around the door. Hold the gun about 6 in. away. |

|

|

| 2. Spray the outside top edges. Hold the gun at 45 degrees and make a second pass all the way around. |

|

|

| 3. Spray the inside top edges. Again, hold the gun at 45 degrees. Keep the gun moving to prevent finish from building up in the corners. |

|

|

| 4. Spray the bevels of the panels. Continue to hold the gun at 45 degrees. If your panel is prefinished, naturally you’d skip this step. |

|

|

| 5. Spray all the top surfaces. Hold the gun at 90 degrees. Spray two continuous coats for full and even coverage. Spray from side to side, then rotate the gun and spray from top to bottom. |

|

|

Cleaning the Gun

At the end of a day of spraying, take 15 minutes to clean the gun. If you skip this step, the gun may not spray properly.

Empty the cup and fill it with warm water. Adjust the air cap to make a round fan pattern, reduce the air volume and increase the fluid volume. Then follow these steps:

| 1. Spray warm water into a bucket until the water is clear. This cleans the internal fluid passages inside the gun. Empty the cup. |

|

|

| 2. Disassemble the gun, removing every part you can. Clean off dried finish with warm water and a brass brush. Make sure the holes in the air cap are clean and free of finish. Poke them with a dull sewing needle or toothpick. |

|

|

| 3. Lubricate the gun. Wipe petroleum jelly on all threaded or movable parts. Reassemble the gun. |

|

|

Oops!

Mistakes are inevitable as you learn to spray. I’ve made some whoppers, but I’ve come to consider them as opportunities, not failures! With each opportunity, you’ll become more familiar with fine-tuning the gun’s adjustments and holding the gun while spraying.

Fortunately, most mistakes are easy to fix by sanding. Waterborne finish dries very fast. When you mess up, wait an hour, sand and spray it over.

Runs, Drips and Errors:

Yuck. Trying to be careful, I moved the gun too slow while spraying the side of a cabinet. Or maybe my fluid volume was too high, I don’t know. In any case, I let the mess dry, shaved off the excess with a utility knife and then sanded. Next time I’ll check my adjustments by spraying on a piece of paper first and make sure I keep the gun moving. |

|

|

Missed Overlaps:

Cheapskate! What was I thinking? That I’d save finish by hardly overlapping at all? It’s not worth it, because here I’ve got a rough looking texture between the spray coats. Actually, I just couldn’t see where the fan pattern hit the surface, so I couldn’t judge the overlaps properly. What I really need next time is a bright, low-angle light. |

|

|

Bubbles in the Finish:

I told everyone I really wanted the finish to look like Mars! Unfortunately, no one bought it. Bubbles mean the coat is too thick. Air got trapped below the finish as the surface dried. I waited until the finish hardened, then sanded out the offenders. To spray a lighter coat, I’ll either increase the air flow, decrease the fluid volume or move the gun faster. |

|

|

Pools of Finish at the End:

There’s a wading pool-size puddle at the end of this top. What happened? I must have started this pass by aiming right at the end, and then pulled the trigger. I know that’s not the right technique, so I’ll repeat to myself as I move my arm, “aim at a spot just beside the top, and then pull the trigger.” In fact, I vow to keep practicing until it becomes second nature! |

|

|

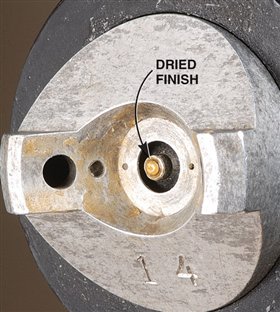

Clogged Needle:

Now what? My gun quit on me after I took a coffee break! No, the gun’s not at fault. While I was relaxing, finish dried on the cap and formed a hard bubble over the needle. No problem, I can clean it right off with a toothpick. Now I always check the cap for dried finish if I put the gun down for a few minutes. It’s as much a habit as taking coffee breaks! |

|

|

Sources

Note: Product availability and prices are subject to change.

Sprayable Waterborne Finishes

These waterborne finishes are specifically

formulated for spraying with an HVLP system. This is just a sampling;

there are many others on the market.

Apollocoat AquaClear, advmachinery.com, 800-727-6553.

Crystalac, crystalac.com, 631-207-0328.

EF

Pro-series, generalfinishes.com, 800-783-6050.

Enduro

Wat-R-Base, compliantspraysystems.com, 800-696-0615.

Hydrocote, hydrocote.com, 800-229-4937.

PianoLac, pianolac.com, 845-855-0996.

This story originally appeared in American Woodworker July 2003, issue #101.

July 2003, issue #101

Purchase this back issue. |

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.