We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Designing sag-proof shelves.

Designing sag-proof shelves.

Have you ever heard a shelf groan? Well, maybe not, but some shelves look like they would if they could. So much stuff gets piled on them that they end up sagging like a limp noodle. It’s not a pretty sight. A span that holds up weight should look strong and sturdy. Even a slight sag sends an unappealing visual message.

A shelf sags in two stages. There’s a small sag when you first put weight on the shelf. This sag, or deflection, increases as more stuff is loaded on the shelf over the years. The shelf keeps on sagging, a little more each year, because wood slowly but surely changes shape under a load. This characteristic of wood is called “creep.” Arm yourself for the fight against creep with common sense engineering knowledge about how each dimension of a shelf affects its strength, or rigidity (Fig. A).

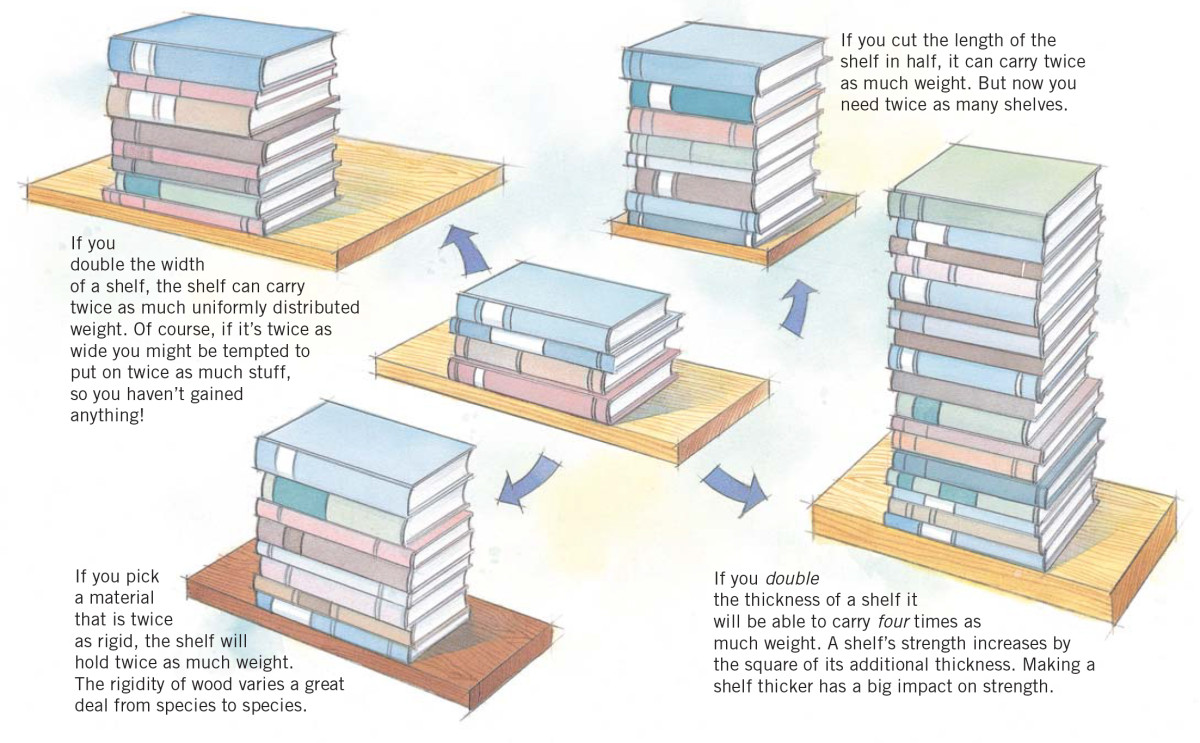

The most important dimensional factor is a shelf’s thickness. The effect of the other two dimensions, width and length, is straightforward; add 10 percent to the width of a shelf, and it’s 10-percent more rigid; add 10 percent to the length, and it’s 10-percent less rigid. However, add 10 percent to the thickness of a shelf and it’s 21-percent stronger! Strength increases at an exponential rate as you add thickness. That’s why wooden joists and steel beams stand on edge. A shelf that’s 7/8-in. thick is about 36-percent stronger than a 3/4-in. thick shelf. If you’re careful, you should be able to get 7/8-in. thick boards from 4/4 lumber. With such a substantial increase in rigidity, it’s definitely worth the effort.

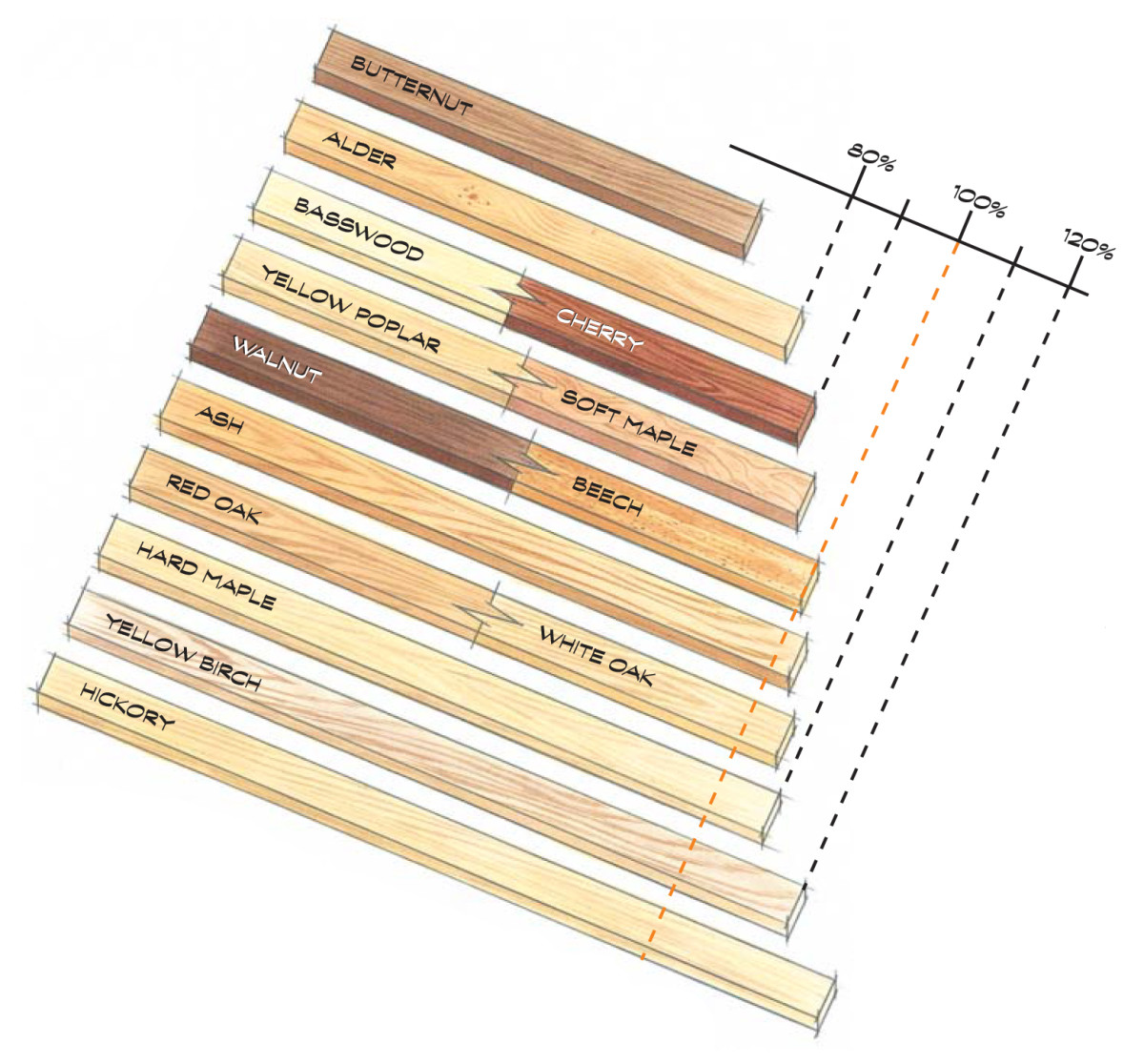

Fig A. Changing any dimension affects the rigidity of a shelf. The biggest returns come with adding thickness and choosing a strong material. These two factors are the foundation of sag-proof shelf design.

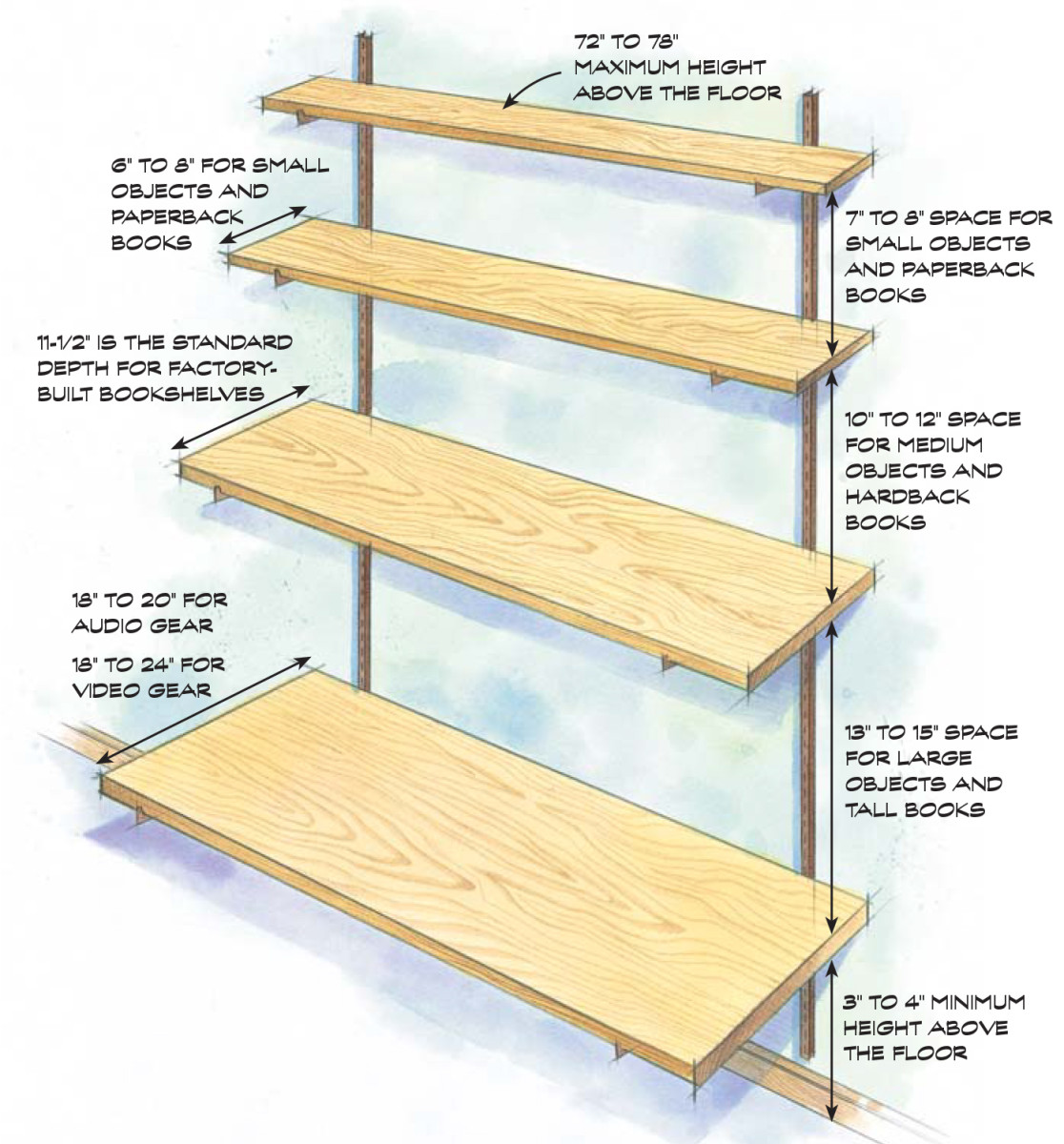

Shelving Standards

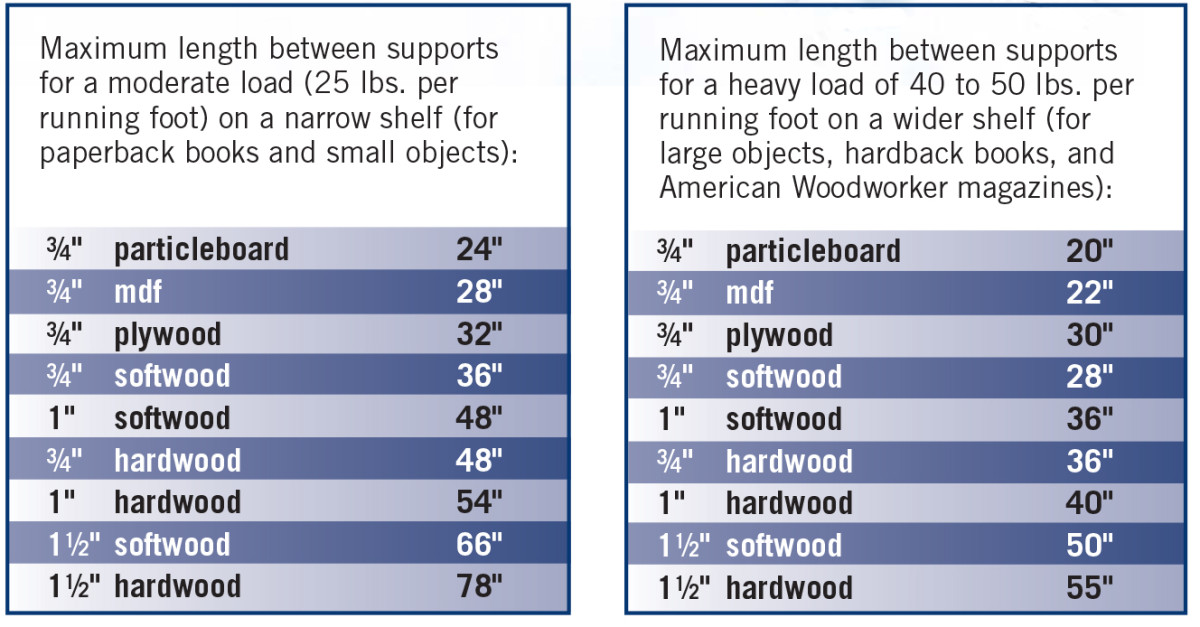

Let’s put our common sense engineering to the test. How wide or long does a cherry shelf have to be to hold up, say, a set of encyclopedias? We can use standard dimensions that have proven themselves reliable over the years to answer this question.

Encyclopedias are large books, so we need a shelf that’s at least 12-in. deep. (Books look best when they sit 1-in. or so back from the front edge of a shelf.) How heavy are they? It wouldn’t be a bad idea to place them on a bathroom scale and find out. Books and magazines can be surprisingly heavy. These standards suggest they’ll weigh up to 50 lbs. per running foot.

Encyclopedias are large books, so we need a shelf that’s at least 12-in. deep. (Books look best when they sit 1-in. or so back from the front edge of a shelf.) How heavy are they? It wouldn’t be a bad idea to place them on a bathroom scale and find out. Books and magazines can be surprisingly heavy. These standards suggest they’ll weigh up to 50 lbs. per running foot.

Fig B. Here are some guidelines for sizing shelves that are supported at the ends by brackets. The maximum length of a shelf increases when you use thicker stock and stronger material.

How long should a 3/4-in. cherry shelf be to hold up these books? The standards tell us that a wide hardwood shelf that carries a heavy load should be no more than 36-in. long. But this doesn’t tell us the whole story, and that’s why we have to look at one more variable before we can build this shelf with confidence.

How Strong Is the Wood?

Some species of wood are much more rigid than others. In terms of deflection under a load, hickory is about twice as strong as butternut. If we make similar shelves out of hickory and butternut, and apply the same load, the butternut shelf will sag twice as much. If we cut the butternut shelf in half, it will sag the same amount as the hickory shelf.

The shelving standards are based on averages. Is our cherry encyclopedia shelf average? No, cherry is more than 10 percent weaker than an average wood like walnut or soft maple (Fig. C). Thus, the shelf has to be shorter or thicker.

Fig. C: Rigidity of Common Wood Species. Wood species vary dramatically in rigidity. Standard shelving dimensions are based on using a wood of average strength, such as walnut. To find out how much shorter or longer a shelf of another wood should be, multiply the suggested length by the percentages above.

Plywood and Composite Woods

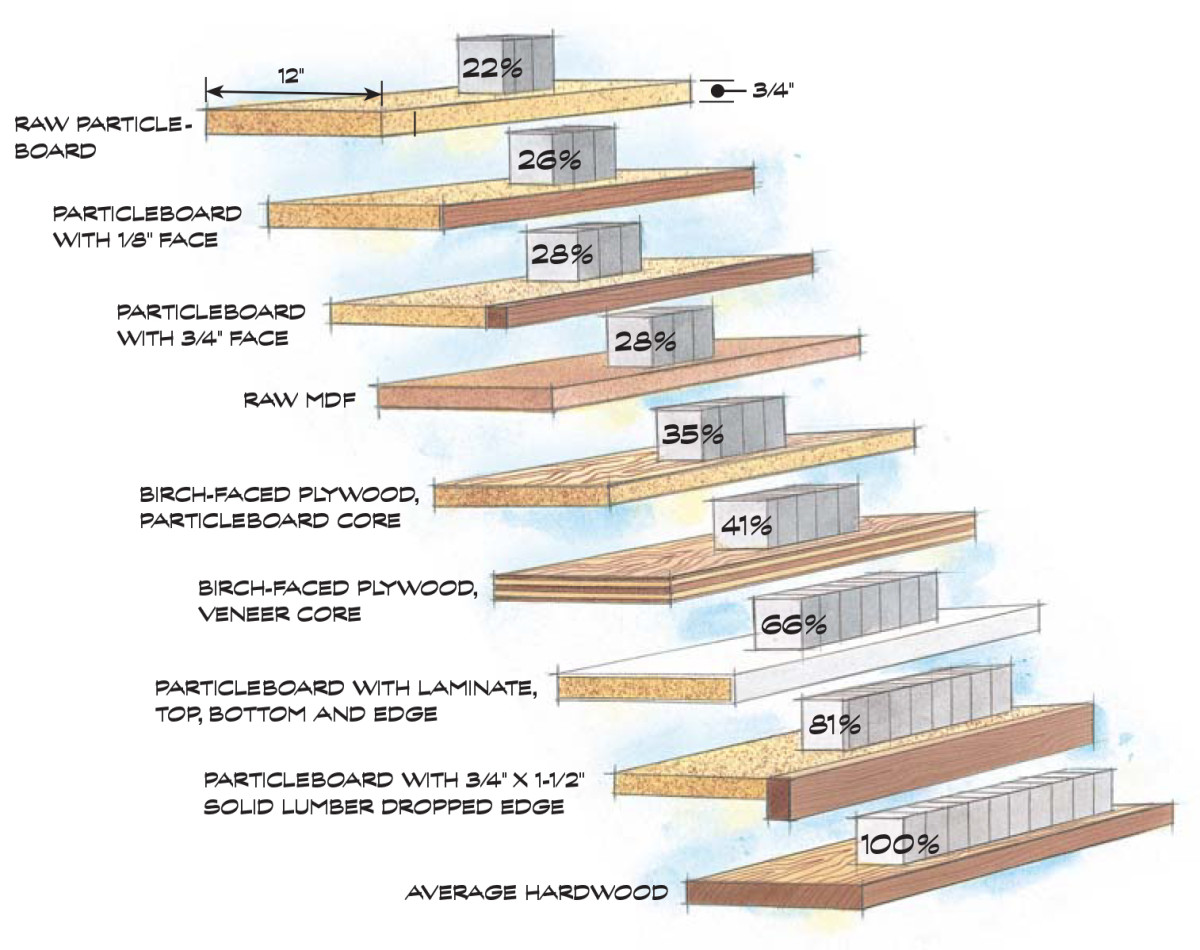

Manufactured wood products are not as strong as solid wood. Plywood is only about half as rigid as the average hardwood because it’s made of alternating layers of thick veneer. Wood is not as rigid across the grain as along the grain. In a shelf, the grain of some of the veneer layers runs the long way, but almost half runs the short way.

Particleboard and MDF (medium density fiberboard), collectively called composite woods, do not have the grain structure of solid wood or of plywood veneers. These products have a hard time holding up their own weight. They have about onequarter of the strength of an average wood. Nevertheless, composite wood is widely used for shelving. Comprehensive information on sizing composite wood shelves is available from an industry trade association.

The rigidity of plywood and composite wood can be improved by gluing on solid wood edges or plastic laminate faces (Fig. D.)

Fig D. Each of these shelves is the same thickness, length, and width. The solid wood shelf holds up four times the weight of the plain particleboard shelf. If the shelves were narrower, adding solid wood and laminate would help even more.

How to Strengthen a Shelf

After weighing the encyclopedias, you may find that they exceed the limits of the standards. In that case, we need to make a more rigid shelf. We could widen the shelf from 12-in. to 16-in., an increase of 25 percent. That would make the shelf 25-percent stronger. It’s an option, but for the sake of argument let’s say that a 16-in. shelf is too deep for our design. What else could we do?

We could shorten the shelf. Like width, it’s a straight percentage reduction. A shelf that is 25 percent shorter will also hold up 25 percent more weight.

A shorter shelf for our encyclopedias isn’t going to work, however. With all the supplements added to it, there’s more than three feet of books! How about making the shelf thicker? If we’ve already purchased 3/4-in. stock, this option is out.

It’s time to be creative about building a shelf that will be stronger than just one solid board. The simplest solution is to add a lip or two to the shelf. Rip some of the 3/4-in. stock into 1-1/2-in. wide strips, turn them on edge, and glue them onto the front and back edges of the shelf (Fig. E). If you need considerably more strength, make the rear strip several inches deep.

Fig E. Add a lip to take advantage of the thickness multiplier effect. If the shelf is made of relatively weak wood, consider using stronger wood for a back lip.

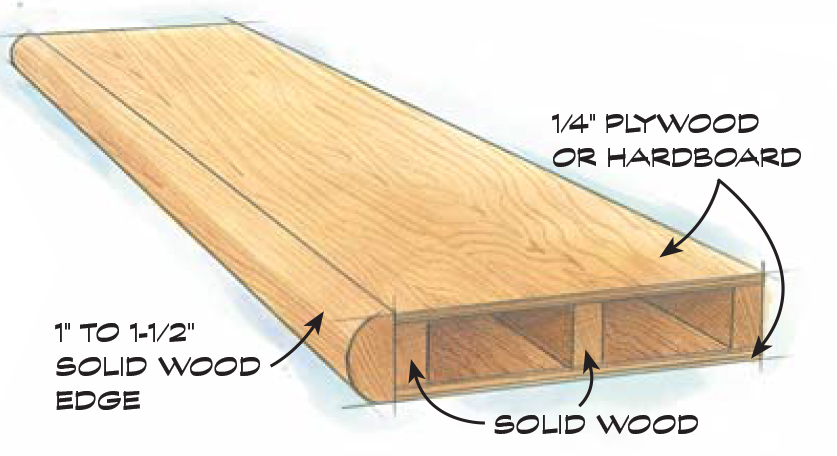

Another way to add thickness to a shelf without using expensive thick lumber is to make a hollow shelf 1- to 1-1/2-in. thick from thin plywood and strips of solid wood (Fig. F). This type of shelf is based on the engineering principles of a torsion box. It’s light in weight but very strong. Use it to carry very heavy loads.

Fig F. Build a torsion-box shelf for light- weight rigidity. All the parts are glued together. It will almost be as rigid as if it were built of solid wood of the same thickness.

Housing a shelf into the sides of a case will enable the shelf to carry more weight. A fixed shelf is more rigid than a loose shelf because its ends are joined to the sides at a stiff right angle (Fig. G). Some joints are stronger than others, so choosing one kind over another can also effect the strength of a shelf. A plain dado works fine, but a sliding dovetail is stronger because it has more mechanical strength and a larger glue surface area.

Fig G. House a shelf to take advantage of the strength of a glued joint. The sides of a case hold a fixed shelf at a rigid right angle. Fasten a fixed shelf to the case’s back for even more rigidity.

Supporting a shelf in the middle strengthens a shelf more than you might think (Fig. H). Weight on one side of a middle support helps hold up weight on the other side, like kids on a see-saw. The net effect is that one long shelf with a center support can hold up more weight than two shorter shelves.

Fig H. Multiply strength by adding a center support. The shelf can then hold up more than twice the weight of two shorter shelves.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

To strengthen cheap IKEA-style shelves, I use some 3/4″ aluminum U-channel on the rear-side of the shelves. Makes them able to hold up to some pretty heavy loads without deflection.

Can we use that as a workshop tip? Email me at cknoff@aimmedia.com with your name if that’s ok.

Another means of stiffening shelves is with a back panel, if firmly attached along the back edges of the shelves (back panels are often just attached around the perimeter of the back panel, and don’t support the shelves at all.)

Rather than one big back panel, fitting individual back panels in between the shelves works too. Even 1/4″ plywood is amazingly good at stiffening the shelves, and also helps prevent racking of the whole shelving unit.

There’s a lot of very specific numbers and ratios being stated as fact in this article without presenting any sources or data to support them. Where did this information come from?

– “add 10 percent to the length, and it’s 10-percent less rigid”

False: 33 percent less rigid assuming the same weight; in realty probably 46 percent less rigid since you will probably use the remaining space to add 10% in weight

“add 10 percent to the thickness of a shelf and it’s 21-percent stronger”

False: 33 percent

“Strength increases at an exponential rate as you add thickness”

False: polynomial rate

“A shelf that’s 7/8-in. thick is about 36-percent stronger than a 3/4-in. thick shelf”

False: about 59 percent

… and so on…