We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Divided Light Doors

Add a masterful touch with classic glass doors.

By Tom Caspar

With the right set of router bits, a divided-light door is a lot easier to make than it looks. The key to success is simple: Measure and cut every single part first. To get you going on the right path, I’ll show you a foolproof way to calculate the precise length of every piece. Then you rout, mortise and assemble. Piece of cake.

Tools you’ll use

To build these doors, you’ll need a router table and a set of special bits (see Sources, below). You’ll also need a metric ruler, tablesaw, planer, jointer and some means of making mortises.

Design your door

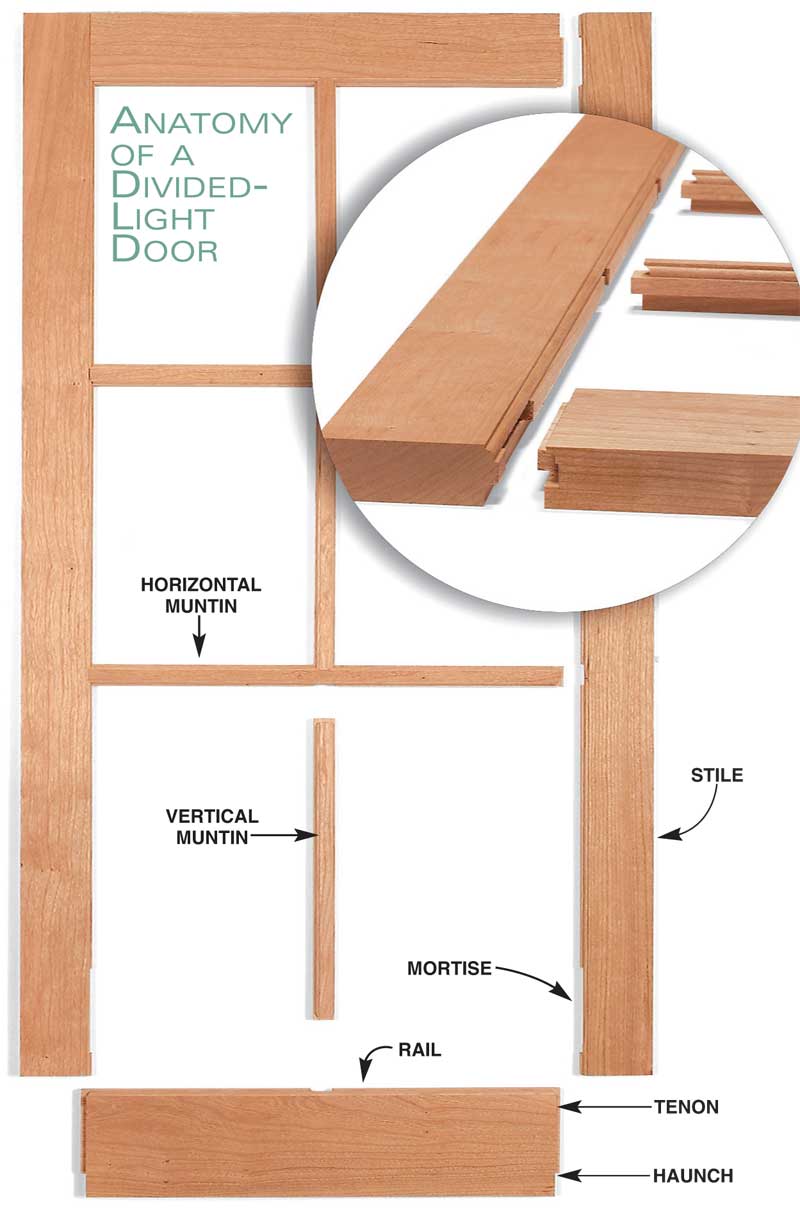

Let’s start with some old fashioned terms. The openings for the glass are traditionally called lights. They’re “divided” by bars called muntins.

Start by drawing your door. Determine the door’s overall size, the widths of the stiles, rails and muntins, and the size of the lights.

Next, select a set of divided-light door router bits. Each set is designed for a specific range of door thicknesses and requires a different setup, but the general steps are the same. Visit the manufacturers’ Web sites for details. We used bits from Freud (see photos below). They’re suitable for doors from 13/16 to 1-1/8 in. thick with 5/8-in. or wider muntins. These bits make tenons; some other sets do not.

Start cutting parts

Mill all the door parts to final thickness (7/8 in. for this door). Make a few extra boards the same size as the rails. Use these for making the muntins and for testing the router bit and mortising machine setups. Crosscut all the pieces a few inches long.

Rip and joint the stiles and rails to final width. Cut the stiles to final length. Leave the rails and muntin boards long. The muntins will be 3/4 in. wide, but don’t rip them yet. Leave them as part of a wider board.Three major parts make a divided light door: stiles, rails and muntins. Every part is locked in place by a mortise-and-tenon joint. In this six-light door, the two horizontal muntins are the same length as the rails. Three short vertical muntins fit between the rails and horizontal muntins.

Although proportions vary among furniture styles, in this door the lower rail is 1-1/2 times as wide as the top rail. All the lights are the same size and evenly divided.Click any image to view a larger version.

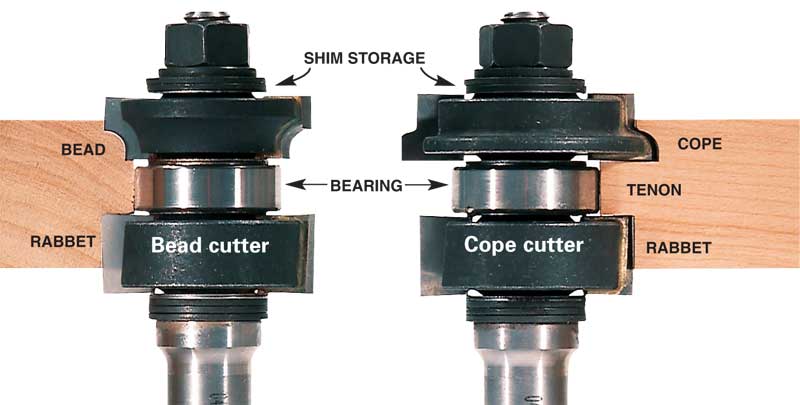

Two matched router bits cut all the profiles. The cope cutter shapes the ends of all the rails and muntins. It also forms a short tenon and a rabbet to receive the glass. The bead cutter shapes the long edges of the stiles, rails and muntins. It also forms a rabbet.

Two matched router bits cut all the profiles. The cope cutter shapes the ends of all the rails and muntins. It also forms a short tenon and a rabbet to receive the glass. The bead cutter shapes the long edges of the stiles, rails and muntins. It also forms a rabbet.

Both bits may be adjusted to fine-tune the tenon’s thickness. You simply take apart the bit and add shims above the bearing. These shims come with the bit and are stored under the nut and washers.

Determine the length of the rails and muntins

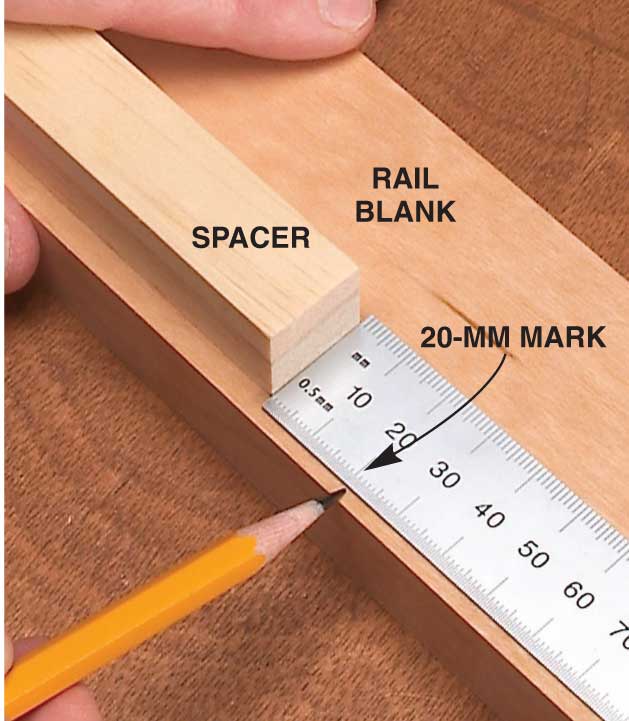

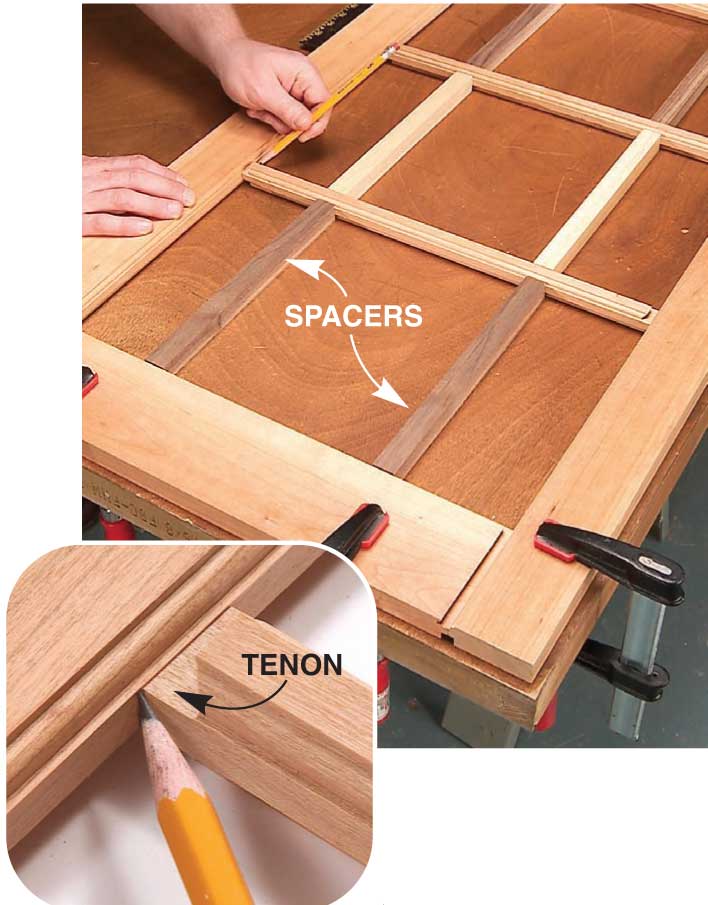

Cut every part of the door to exact length in these steps. Use the actual stiles to calculate the precise length of the rails and muntins. 1. Cut two spacers to spread the stiles to the door’s final width. This method prevents you from making a math error with awkward fractions in the next step. 2. Add the length of two tenons to the spacer and mark this total distance on a rail blank. With the Freud bits, two tenons are equal to 20 mm (about 25/32 in.) Crosscut the rails and horizontal muntin boards to this length.

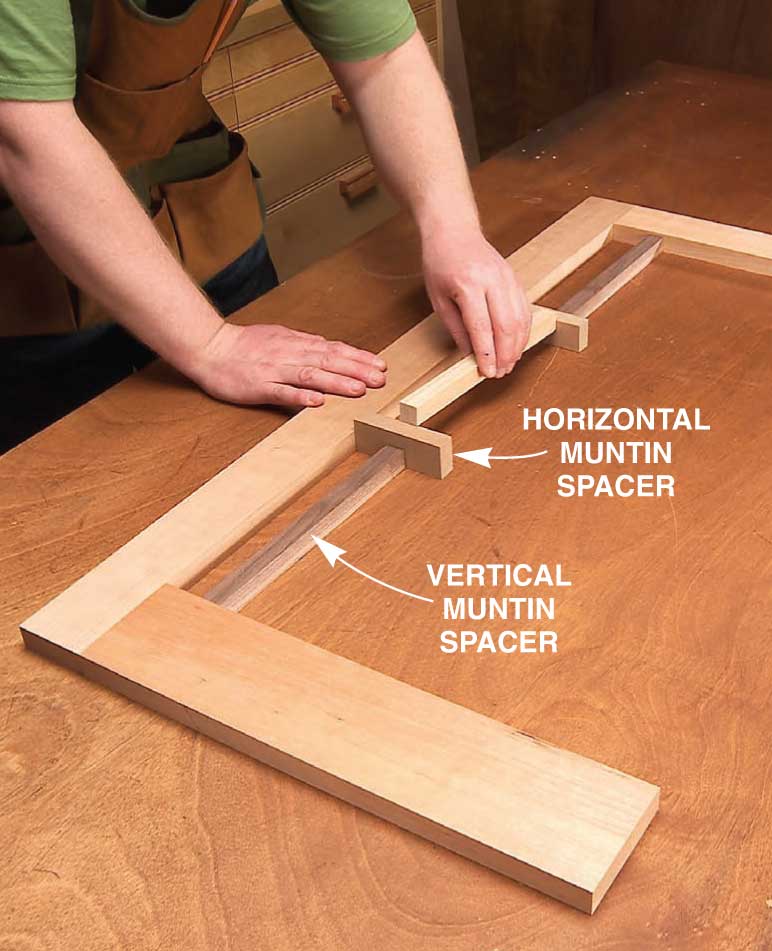

2. Add the length of two tenons to the spacer and mark this total distance on a rail blank. With the Freud bits, two tenons are equal to 20 mm (about 25/32 in.) Crosscut the rails and horizontal muntin boards to this length. 3. Use the same process to calculate the vertical muntin boards’ length. Position two 3/4-in.-thick blocks to stand in for the 3/4-in.-wide horizontal muntins. Cut two top and bottom spacers the same length. Then cut a middle spacer to fit. Add 20 mm to these spacers to mark and cut the vertical muntin boards.

3. Use the same process to calculate the vertical muntin boards’ length. Position two 3/4-in.-thick blocks to stand in for the 3/4-in.-wide horizontal muntins. Cut two top and bottom spacers the same length. Then cut a middle spacer to fit. Add 20 mm to these spacers to mark and cut the vertical muntin boards.

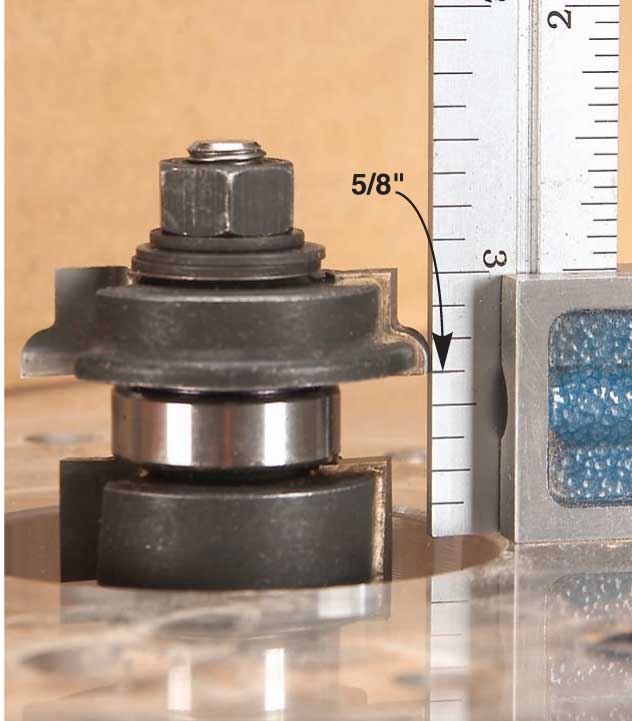

Cope the ends

Next, cut tenons on the end grain of every part. Coping the ends before cutting the beads minimizes problems with grain tear-out. 4. Set up the cope cutter. For a 7/8-in.- thick door like this one, raise the bit so the top cutter is 5/8 in. above the table. Position the router table fence so the cutter bearing is perfectly even with the fence or 1/64 in. proud. This assures a full-depth cut, which is necessary for a good fit.

5. Test cut an extra piece of rail stock. Clamp a backing board to the workpiece to prevent tear-out. Use a push pad to keep the workpiece flat on the table and your fingers out of harm’s way.

5. Test cut an extra piece of rail stock. Clamp a backing board to the workpiece to prevent tear-out. Use a push pad to keep the workpiece flat on the table and your fingers out of harm’s way. 6. Measure the tenon’s thickness. It should be 5/16 in. so it fits the mortise made by a 5/16-in. chisel. If the tenon is too thin, add shims above the bearing (see inset). Add the same shims to the bead cutter. When the tenon is correctly sized, cope the ends of all the rails and muntin boards.

6. Measure the tenon’s thickness. It should be 5/16 in. so it fits the mortise made by a 5/16-in. chisel. If the tenon is too thin, add shims above the bearing (see inset). Add the same shims to the bead cutter. When the tenon is correctly sized, cope the ends of all the rails and muntin boards.

Rout the bead

The bead goes on the long grain of the stiles, rails and muntins.

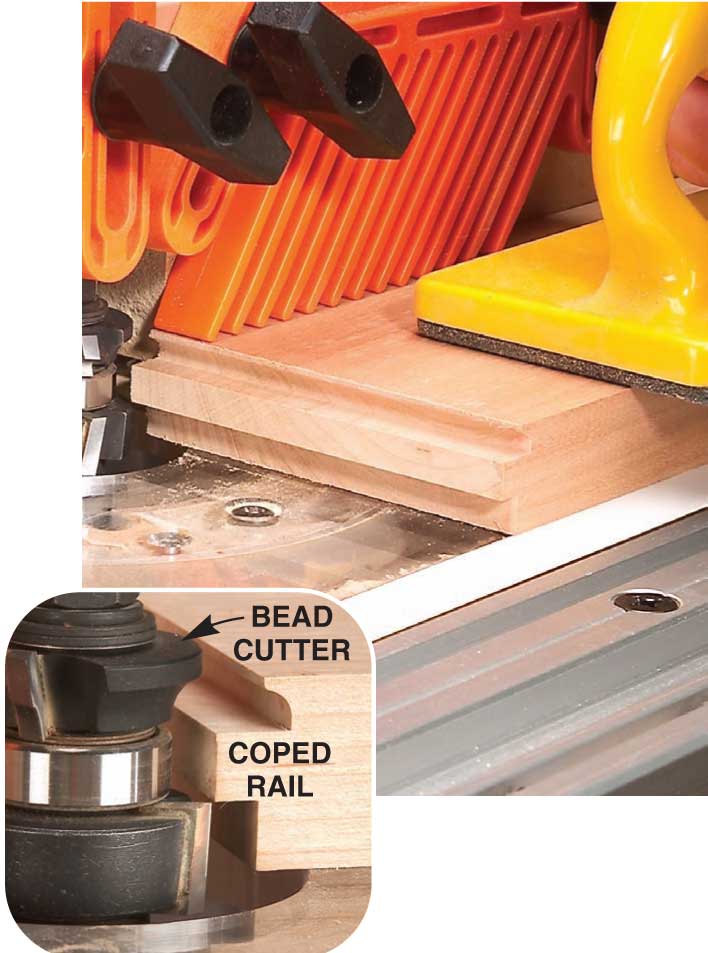

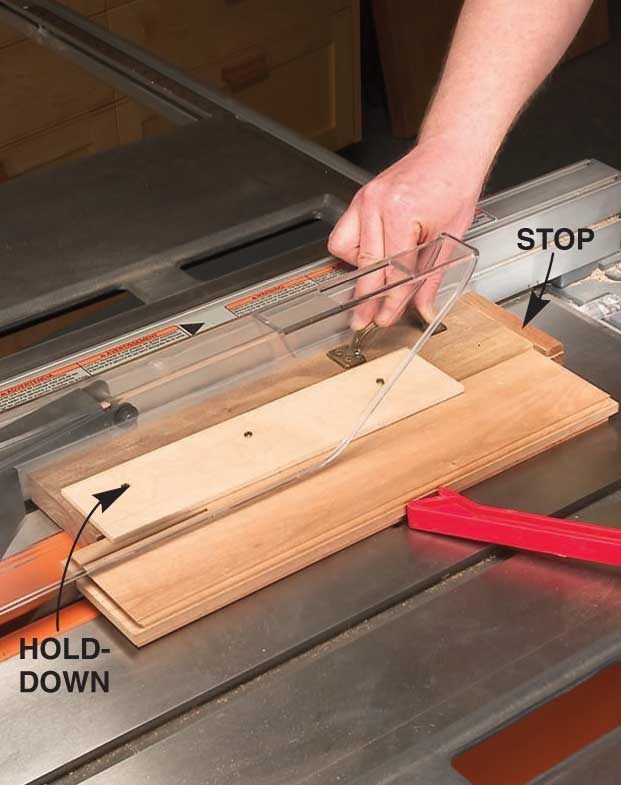

7.Rout beads on the inside edges of the stiles and rails. Position the bit so the lower knife is level with the rabbet made by the coping cut (see inset). Cut beads on both sides of the muntin boards. 8. Rip the muntin boards. Use a push block with a stop and hold-down board so you can keep the guard and splitter on your saw. The exact width of this cut—3/4 in.—must be the same as the width of the stand-in muntin blocks you used to calculate the vertical muntin’s length in Photo 3.

8. Rip the muntin boards. Use a push block with a stop and hold-down board so you can keep the guard and splitter on your saw. The exact width of this cut—3/4 in.—must be the same as the width of the stand-in muntin blocks you used to calculate the vertical muntin’s length in Photo 3. 9. Rout the second side of the muntins. Use the same push block as you did on the tablesaw. This time the push block is flipped over and the hold-down removed.

9. Rout the second side of the muntins. Use the same push block as you did on the tablesaw. This time the push block is flipped over and the hold-down removed.

Caution: You must use two featherboards to hold the workpiece square to the table.

Cut the mortises

Most routed doors merely have cope and stick joints. Mortise-and-tenon joints strengthen a divided light door to carry the extra weight of the glass.

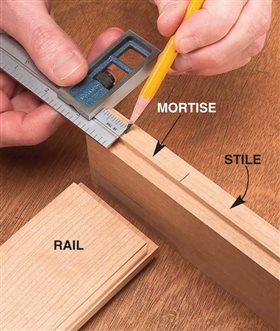

10. Mark mortises on the stiles directly from the rails and horizontal muntins. Position the muntins with the spacers you made earlier (see Photo 3). Draw pencil lines along both sides of the tenons (see inset). Mark mortises for the vertical muntins in the center of the rails and horizontal muntins. 11. Mark the outer end of each rail mortise that will receive a rail. Typically, this mark is about 3/4 in. from the stile’s end.

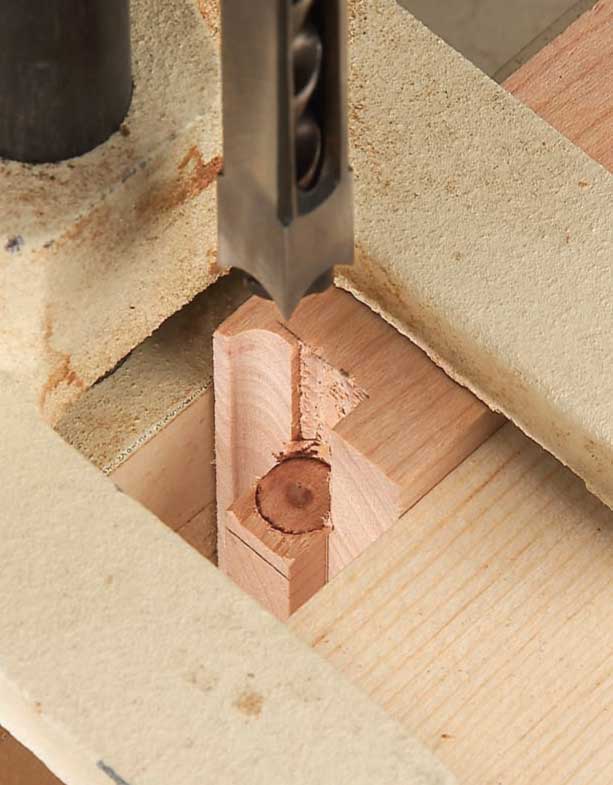

11. Mark the outer end of each rail mortise that will receive a rail. Typically, this mark is about 3/4 in. from the stile’s end. 12. Cut mortises in the muntins halfway through from both sides. Place a support block under the muntin so its top edge is within range of the machine’s hold-down. Cut 1/2-in.-deep mortises in the rails and stiles.

12. Cut mortises in the muntins halfway through from both sides. Place a support block under the muntin so its top edge is within range of the machine’s hold-down. Cut 1/2-in.-deep mortises in the rails and stiles.

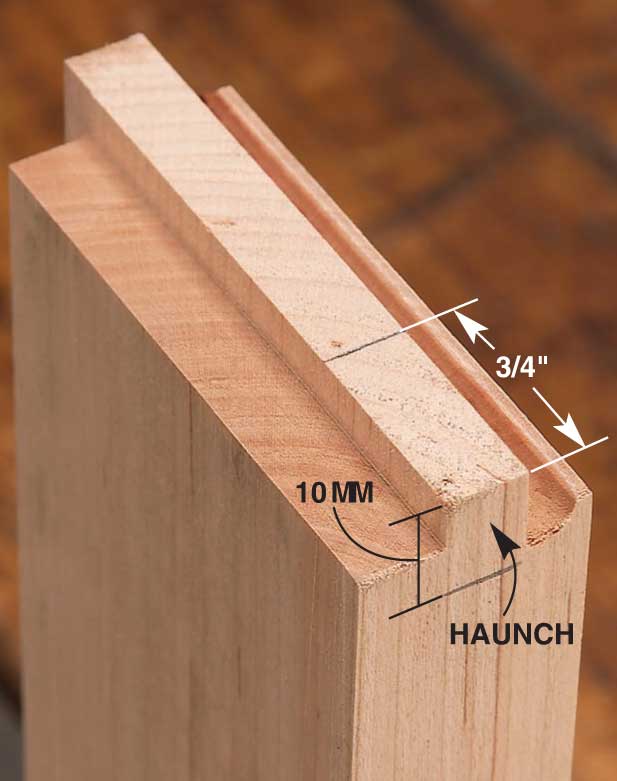

Haunch the rails

Remove the outer part of the rail tenons to fit the mortises.

13. Mark the waste on the tenon’s end with a combination square. 14. Remove most of the waste with a mortising bit. You don’t have to move the machine’s fence. This is the same setup you used for cutting mortises in the rails and stiles.

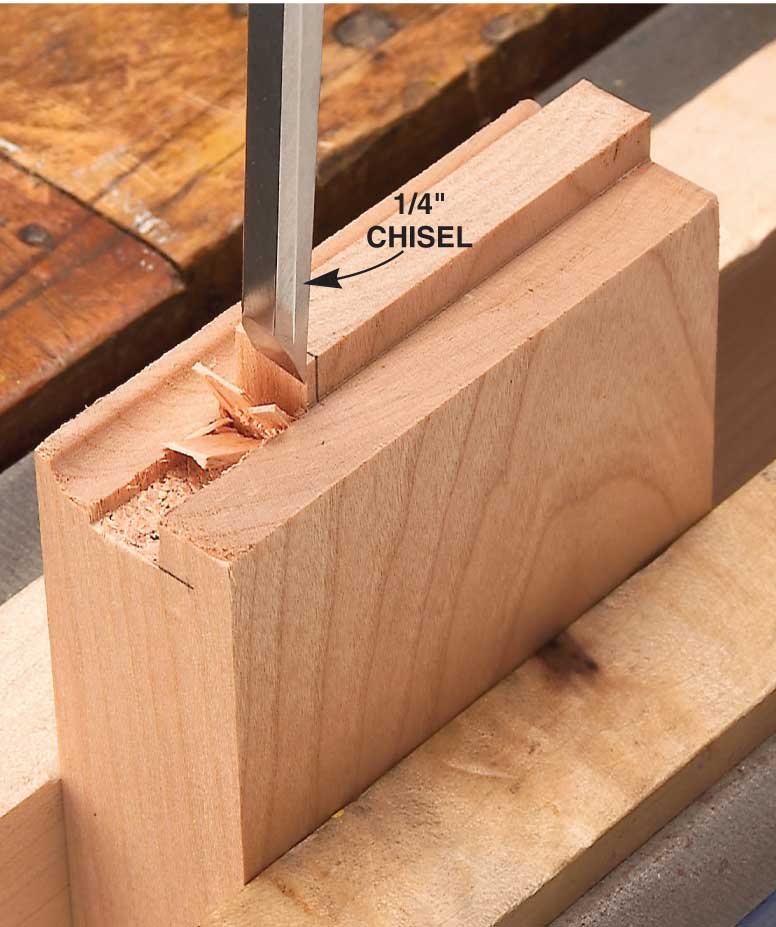

14. Remove most of the waste with a mortising bit. You don’t have to move the machine’s fence. This is the same setup you used for cutting mortises in the rails and stiles. 15. Pare the tenons to width. Check the fit of all the tenons in the mortises. File small bevels on the ends of all the tenons so they’re easier to insert into the mortises.

15. Pare the tenons to width. Check the fit of all the tenons in the mortises. File small bevels on the ends of all the tenons so they’re easier to insert into the mortises.

Assemble the door

The entire door must be glued at one time. It’s best to work directly on a large, flat assembly table so you can slide each piece home before clamping it.

16. Cut 1/16 in. off the ends of the vertical muntin tenons. As originally routed, each tenon is slightly over 3/8 in. long. That’s too long for the through mortises in the horizontal muntins, which are 3/4 in. wide. 17. Glue the door. Squeeze-out around the beads can be difficult to clean up, so use a minimum of glue. Sand and finish the door before you install the glass.

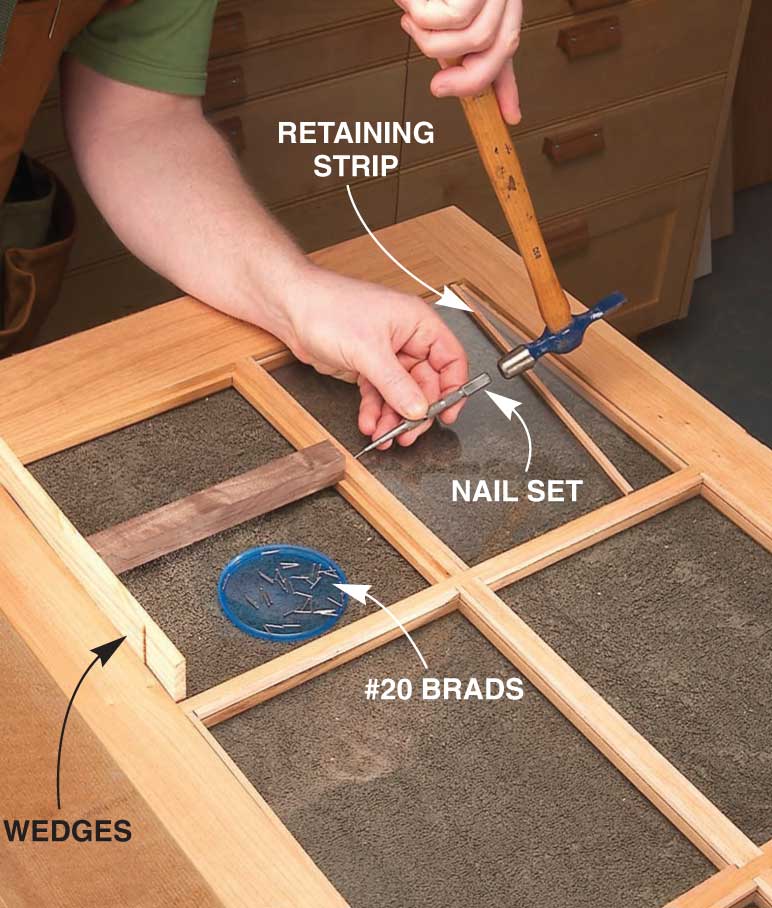

17. Glue the door. Squeeze-out around the beads can be difficult to clean up, so use a minimum of glue. Sand and finish the door before you install the glass. 18. Nail small retaining strips to hold the glass. Predrill angled holes in the 3/16-in. square strips using a nippedoff brad as a drill bit. Support the muntin with a spacer block wedged in the opposite opening. Use a nail set to keep the hammer’s head away from the glass.

18. Nail small retaining strips to hold the glass. Predrill angled holes in the 3/16-in. square strips using a nippedoff brad as a drill bit. Support the muntin with a spacer block wedged in the opposite opening. Use a nail set to keep the hammer’s head away from the glass.

Sources

Note: Product availability and prices are subject to change.

CMT, cmtusa.com, 888-268-2487, Divided-light door set, #800.525.11.

Freud Tools, FreudTools.com, 800-334-4107, Divided-light cabinet door bit set for 13/16- to 1-in.-thick stock, #99-270.

MLCS, mlcswoodworking.com, 800-533-9298, Window-sash bits for 7/8 in. to 1-1/2 in. thick stock: a single reversible bit, #8893; a two-piece matched set, #8894; Miniature stile-and-rail bits for 1/2- to 3/4-in.-thick stock, #8848.

This story originally appeared in American Woodworker July 2005, issue #115.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.