|

Want to make your head spin?

Just try to figure out how hardwood

lumber is graded.Lumber is such

an incredibly diverse material that there

are enough grades, rules for grading

and exceptions to the rules to make

you dizzy.Professional lumber graders

use standards, administered by the

National Hardwood Lumber Association,

to classify every board.While you

don’t need to be a pro, knowing the

difference between No. 1 Common and

the higher “select”grades can keep you

from wasting your money.

Everybody likes to buy “the best.”But

when choosing lumber, it’s a mistake to

pay top dollar for big, clear boards if

you’re going to cut them up into small

pieces.The best boards to buy aren’t

always the most expensive ones.

No. 1 Common is great for furniture

Take a look at No. 1 Common lumber.

It costs a lot less than the higher grades

because the boards are smaller and

they’ve got some knots and other

defects.They also contain a lot of perfectly

clear material.You just have to be

willing to buy a little extra stock and

spend some time working with it. It

can be a challenge to figure out how to

harvest the pieces you need, but it’s

also enjoyable and rewarding when

you do.

No. 1 Common lumber is well suited

to furniture making. It’s an economical

source for narrow stock, perfect for

moldings, or stiles and rails for face

frames and frame-and-panel structures

like doors or cabinet sides.You’ll

also find boards in the common pile

that are wide, with enough clear

lengths between defects to make goodlooking

panels, cabinet sides or small

tabletops.

You can find treasure boards in No.1 Common.

No. 1 Common lumber often contains

striking grain and figure patterns that

are usually absent in the select grades.

That’s because these “abnormalities” often occur around knots and near

other natural defects.With selective or

innovative cutting, you can remove and

showcase them.Or perhaps you prefer

a look that includes knots, splits and

natural edges. Common grade boards

can be downright beautiful, making

more expensive higher grade boards

look plain by comparison!

The real difference: a pretty face

When you look at a chart of the various

lumber grades (Fig.A, below), No. 1

Common appears to be a full step lower

than Selects and Better. But look

closely—the difference is really only a

half step.

First, Selects and Better (the highest grade you’re likely to see at most lumberyards)

isn’t the highest grade. It’s a combination of the

top three grades (think Selects and better).To

make Selects and Better, boards only need to

meet the minimum requirements of Selects.

Second, boards are always graded on

both faces. Here’s the rub: To grade

Selects,only one face of a board has to

make the top grade (Firsts and Seconds;

another combination). The

other face only has to make No. 1

Common.That means the difference

between No. 1 Common and Selects and

Better is one (good) face!

The nature of No. 1 Common lumber

No. 1 Common boards usually come from the

interior of large logs or from small logs. The

center of a log, or pith, is unusable. Boards cut

near the pith contain more defects. Boards

from small logs are either narrow or cut close

to the pith.

Expect to find these defects, alone or in

combination, when you look at No. 1 common:

• Knots.The boards are likely to have several

knots, clustered, loose or even open.

• Bark. There’ll be edges containing bark

(wane), including up to one third of a board’s

width and up to half of its length. Light-colored

sapwood, typical in cherry (shown) and walnut,

isn’t considered a defect when grading.You’ll just

find more of it in No.1 Common because of the

smaller logs.

• Bad ends. All it takes to drop a board into

No. 1 Common grade is one bad end. Long or

numerous checks and clusters of knots that

extend more than 12 in. are typical.

• Warp.The boards can be bowed, crooked,

cupped or twisted, as long as the clear cuttings

from them can be planed flat on two sides to the

standard surfaced thickness (13/16 in. for 1-in.

rough stock, for example).

While having a good face is important, the closeness

in quality between these grades, compared with

the difference in price,makes No. 1 Common worth

considering.Remember, just as some of those expensive

Selects and Better boards are going to have one

No. 1 Common side, some of the cheaper No. 1 Common

boards may have one face that’s a gem.

When selects and better is better

It makes sense to buy big,defect-free boards for big,

smooth surfaces, such as table- or desktops, plankstyle

cabinet sides or perhaps a head- or footboard.

A group of Selects and Better boards may have more

consistent color and grain patterns. Defect-free

boards are less distracting to look at and generally

easier to work with.Working with No. 1 Common

takes time and patience.

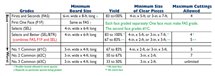

Fig. A: Basic Grade Requirements for Hardwoods

The National Hardwood Lumber Association’s grading

standards are based on the assumption that every board will

be cut into defect-free pieces, called “cuttings,” for use as

furniture components.

A board’s grade depends on the number and size of the clear

pieces it contains. Aesthetics aren’t considered.

This story originally appeared in American Woodworker December 2000, issue #84.

December 2000, issue #84

Purchase this back issue.

|

|

Click any image to view a larger version.

Defects don't make a board defective; just cheaper. If your project calls for

small parts, like stiles and rails, lumber that’s graded No. 1 Common is an economical

choice.You can harvest perfectly good pieces by cutting around the knots.

Finding hidden beauty in an unsightly board is rewarding and well worth the

head-scratching it takes. In spite of serious end checks, an awkward grain pattern and

a waney edge, the $8 piece of No. 1 Common walnut shown above contains all the

parts for an eye-catching cabinet door.There’s straight grain for stiles and rails and a

piece that, when resawn, made a great bookmatched panel.No. 1 Common boards

often contain unusual grain and interesting color and figure. Because these usually

occur around defects, you aren’t as likely to find them in the higher (clearer) grades.

Get more wood for your money! Depending on the

species, No. 1 Common lumber typically costs 25- to 40-

percent less than the next higher grade, Selects and Better.

There are two reasons for this: availability and desirability.

No. 1 Common boards are cheap because the raw material is

plentiful. Most of the boards cut from a log contain too many

natural defects to make the top grades, and boards without

defects are rare. No. 1 Common boards cost less because

they contain a fair amount of unusable material.You get a

price break because you have to buy up to 30 percent more

to compensate for the waste. Don’t worry! The math usually

works out in your favor. Buying No. 1 Common is almost

always cheaper.

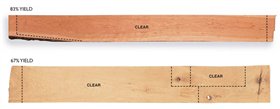

Expect less clear lumber, but don’t be surprised when you get more.

No. 1 Common grade allows defects to occupy up to one third of the board.

But like any grade, it contains boards that barely qualify (bottom) and boards

that just missed being graded higher (top).

Some No. 1 Common is very clear, but simply

short or narrow. If a board is under 6-ft. long, or less

than 4-in. wide, it won’t qualify for a higher grade.

Dark-colored heartwood,

typical in maple, birch and ash, isn’t

considered a defect unless the board is

also specifically graded for light color.

You’ll find considerable dark-colored

heartwood in No. 1 Common grades of

these species, just as you’ll find more

light-colored sapwood in No. 1 Common

cherry and walnut.

Lower grading standards apply to walnut and its close cousin

butternut, allowing smaller boards and more defects.And unlike other

species, the best side of a walnut board is used to determine its grade. In

general, grading rules are tailored to specific species.Walnut trees usually

don’t get to be giants, so the typical log is undersized.That fact is considered

when the boards are graded.

|