|

No more smashed frosting, cracked

crusts or capsized casseroles.You

can take your culinary creations anywhere

with this portable food safe.You

can adapt the design to accommodate

two pie plates, a deep casserole dish or

a 9 in. by 13 in. baking pan. If you’re a

bread baker, size the safe for two loaf

pans with a pull-out cutting board on

the bottom.Whatever you’re toting, it

will arrive in style and in one piece!

Pine’s a good choice for wood

because it’s easy to work and light in

weight.Acrylic doors allow for peeking

and the brass handle is an easy grip.

Total cost: around $35. (Note: The following how-to contains specific instructions

for the food safe pictured here.)

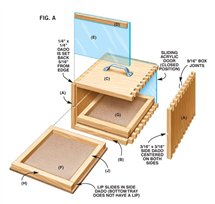

The four sides are wide so you may

have to glue up some stock. Plane the

material to 5/8-in. thickness and mill to

width and length (Fig.A). I like to cut

the parts about 1/16-in. long so each

box joint protrudes about 1/32 in. It’s

better to sand the pins flush to the sides

than the sides flush to the pins! Once

the box joints are milled (Photo 1), take the two side panels and make the

dadoes for the two sliding doors. The

acrylic I used came a little under thickness

so it worked well to make the

dadoes right at 1/4 in. Next make the

dado for the upper sliding tray. Now is

a good time to finish sand the inside

surfaces.

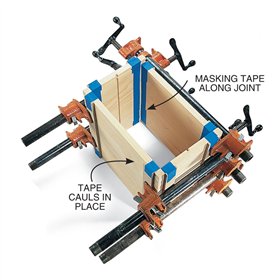

Gluing and clamping all four sides at

once takes four hands; here’s a better way: Dry clamp the four sides, pull the

top off the sides and brush glue onto the

mating surfaces of the exposed pins.

Replace the top and clamp (Photo 2).

Make sure the top is square to the sides.

When dry, flip over and repeat the gluing

process with the bottom panel.

When the glue is dry, you can sand

the joints flush. Cut the tray bottoms

from 1/8-in. hardboard. The

upper tray bottom is wider than the

lower tray because it needs a lip to slide

in the side dado. Cut and attach the

rim boards.

Your hardware store can cut the

acrylic doors for you. If you choose to

cut them yourself, use an 80-tooth, carbide-

tipped triple chip design or a finetooth

steel plywood blade. To remove

saw marks on the edges of the acrylic,

use a sanding block. The wood trim

on the doors serves as a finger grip and

is attached with epoxy. Scuff the acrylic

with sandpaper and tape off any place

you don’t want smeared with epoxy. Peel off the tape when the epoxy is still

semisoft.

Stain and finish to your liking.Add

the handle and you’re ready to go.

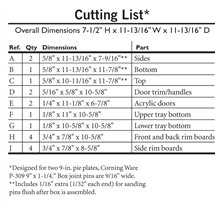

Cutting List

Fig. A:

|

|

Click any image to view a larger version.

1. Routing box joints with a dovetail jig is

very fast (this one is by Keller).The jig is

easy to set up, reliably accurate and can

also be used to make dovetails.

2. Clamp up the box using cauls to clear

the protruding pins.Taping the cauls in

place makes the job easier. For easy

cleanup, line the corners with masking

tape to catch glue squeeze out.

|