We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

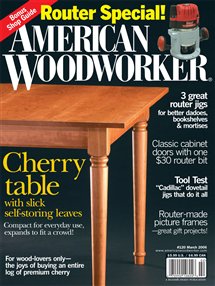

Honey, I Bought a Log!

For perfectly matched boards, I ordered a whole flitch-cut cherry log.

By Joe Gohman

|

I love the look of natural, unstained cherry, but I’ve never had much luck matching its color and figure. Every cherry board I’ve bought at a lumberyard has looked different. Some were red; others were brown. Some were curly; others were plain. Variation isn’t a big problem with many projects, but when I dived into building a huge dining table (see “Cherry Dining Table”), I resolved to be choosy. I wanted showy boards that all looked alike. A dining table is a great opportunity to display beautiful boards. I could have used cherry plywood and glued on solid-wood edges, but I prefer the look of wide, solid-wood planks. Where would that matched wood come from? Clearly, matched boards must come from the same tree, so I would have to buy from a sawmill or lumber company that keeps all the boards from one log together as a unit, called a flitch. A flitch-cut log is sawn in successive layers (see photo, above) and is dried, stickered and stacked as a unit. Flitch-cut logs are sold as whole units or in parts. You may have to buy the whole log or you may be able to pick individual boards. Buying a whole log gives you more options in cutting and arranging pieces, but it’s also more expensive. You’ll probably get more wood than you’ll need for a single project. I turned to the Internet to order my log (see Source, page 57). This was fun! There are many companies to choose from. On many Web sites, I could see photos of every log and every board in each log. Before I ordered, though, I talked to a real person at the lumberyard who told me more about the log, such as the presence of defects, color, figure and expected yield. There are as many different logs as there are trees in a forest. I’ll tell you a bit about the particular log I ordered, but you shouldn’t generalize too much from my experience. First, the price tag. My log cost about $1,000 kiln-dried. Shipping added another $250. That eye-popping price really stretched my budget, but it was worth it. The log was 12 ft. long with center boards 16 in. wide. It was all cut into 1-1/4-in.-thick (5/4) boards. (Many logs are cut into boards that are 1-in.-thick (4/4) or a mixture of thicknesses.) The log contained 170 bd. ft. of 5/4 wood, which works out to be about $6 per bd. ft. That’s about the same price I pay at the lumberyard for top-grade 5/4 lumber, but the yield of this log was substantially less. Flitch-cut wood generally includes an irregular bark edge, all the sapwood and the pith, which is the soft and unstable center of the tree. It may also contain crotches, where the fork of a branch makes the wood grain much wilder. My log had everything: bark, sapwood, pith and a crotch. The crotch was too highly figured to use in my table, but its grain is so cool that I’ve set it aside for another project. My log was sliced into 10 boards. The two outside slices were mostly light-colored sapwood, so I set them aside for use as (expensive) utility wood in other projects. The center four slices were quartersawn and had cracks following the pith. The remaining four slices were plainsawn, wide and relatively defect-free. All in all, my yield was reduced at least 25 percent. On the plus side, I made eight 12 x 48-in. boards with the same striking figure, two more than I needed. I also cut a lot of 4-in.-wide straight-grained boards (the quartersawn and riftsawn portions of the flitch), which were perfect for the table’s aprons. After all that work, this table really looks fabulous. My spouse knows—all too well—that our table is a real conversation piece. Buying a whole log was an expensive but convenient way to get matched boards. It sure makes a great after-dinner story. SourceHearne Hardwoods, hearnehardwoods.com, 888-814-0007, Cherry lumber and logs. This story originally appeared in American Woodworker March 2006, issue #120. |

Click any image to view a larger version. |

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.