|

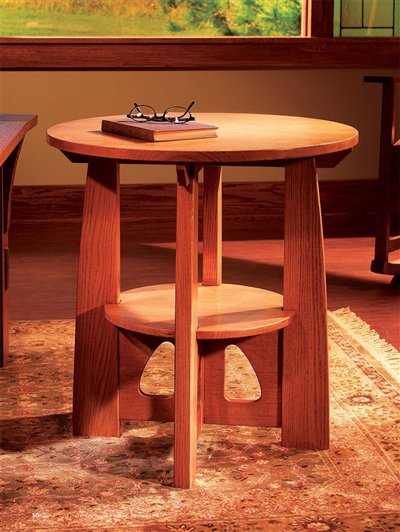

Bold design, strong joints and graceful cutouts.These

are hallmarks of the Arts and Crafts furniture made by

the Charles P. Limbert Company of Holland, Michigan.

In 1910, Limbert designed a large oval library table

that’s become an icon of American design.

Here’s a smaller round version that’s more practical for

today’s homes. All the parts fit together with four

different kinds of half-lap joints made on a bandsaw.

Follow along with us as we turn the bandsaw into a

precision joint-making machine by adding one simple

shop-made jig.

Tools and materials

You’ll need a jointer, planer,

bandsaw, router, router table

and jigsaw to build the table.

We recommend using a 1/2-

in. 4-tpi blade in your

bandsaw. You’ll use two

special router bits; a 1/2-in.

bottom-bearing flush-trim bit ($18) and a 1/8-in.

roundover ($23).You’ll also

need 1-in. and 1-1/4-in.

Forstner or spade bits and a

5/8-in. brad-point bit. (See

Sources, below, for

bandsaw blade and router

bit suppliers.)

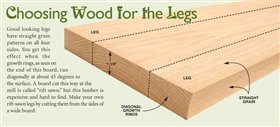

The table requires

approximately 15 bd. ft. of

4/4 and 8 bd. ft. of 6/4

lumber. Our lumber cost

about $100. In keeping with

traditional Arts and Crafts

style, we used quartersawn

white oak for the top, rails

and shelf. It’s hard to find

quartersawn lumber thicker

than 4/4, so we used carefully

selected plainsawn white oak

for the legs (see Choosing

Wood for the Legs).

You’ll also need some figureeight

style desktop fasteners

($5). (See Sources, below,

for quartersawn oak and the

fasteners.)

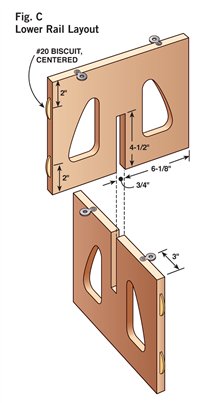

Make the lower rails

Select wood for the lower

rails (E). It’s better to glue

up the rails from two or

three narrow boards rather

than use one wide board.A

wide board might not stay

flat while you build the table,

particularly if you use

plainsawn lumber, and that

would spell trouble in

making the rails’ half-lap

joints.You’ll also need a test

piece (F) for making the

half-lap joints. It must be the

same thickness and type of

wood as the rails. Cut both

rails and the test piece from

one long glued-up blank.

The rails will then match in

color and figure.

1. Joint the faces of the

boards, and plane them 7/8-

in. thick. Then joint both

edges.

2.Glue the boards together,

and scrape off any dried

glue.

3. Run the blank through

the planer, alternating sides,

until it’s 3/4-in. thick. Plane

another piece of wood

(spacer G) to exactly the

same thickness.

4. Rip the blank to final

width, and cut the two rails

to length.

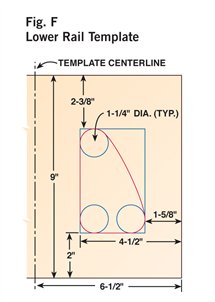

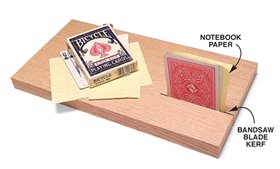

Rout openings

in the rails

1. Make a router template

from 1/4-in. hardboard or

melamine (Fig. F, page 61).

Cut it exactly the same size

as both rails. Drill the three

holes in the template with a

1-1/4-in.bit.Cut the opening

with a jigsaw, staying 1/16-

in. away from the layout

lines. Clean up these rough

cuts with a drum sander in a

drill press or use a file and

sandpaper.

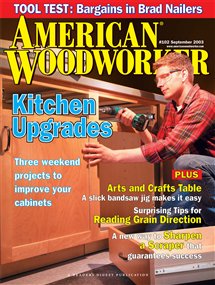

2.Trace the template openings

on the left and right sides of

each rail.Drill 1-in.-dia.holes

in the corners of the cutouts.

Rough cut the openings with

a jigsaw (Photo 1). Avoid

cutting right on the line, but

cut as close as you can,

leaving no more than 1/16-

in.waste.

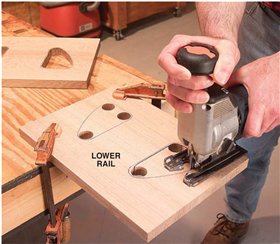

3. Rout the openings with a

1/2-in.-dia. flush-trim bit

(Photo 2).

4. Flip over the template and

tape it to the other half of

the rail. Rout the opposite

opening. Sand the cutouts,

both faces of the rails, test

piece F and spacer G.

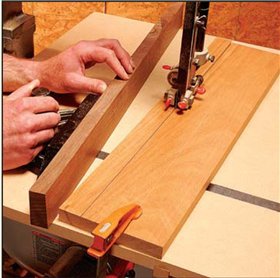

Build an auxiliary bandsaw table

The extra-large half-lap

joints and bridle joints in

this table are safe and easy to

cut on a bandsaw.You’ll need

a fence on your bandsaw,

however. If you don’t have a

fence,we’ve devised a simple

way to turn your tablesaw

miter gauge into a fence by

building a no-fuss auxiliary

table for your bandsaw. It’s generously sized to support

the large pieces of this

project (see Versatile

Bandsaw Table, below).

Perfect half-lap joints

Making perfect-fitting halflap

joints often requires a lot

of trial-and-error cutting,

but we’ve devised a simple

method to eliminate that

extra work. Set the fence for

drift with a 3/4-in.oak board

(see Adjust the Fence,

opposite page).

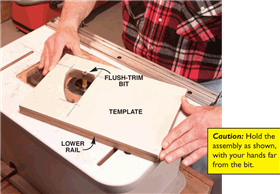

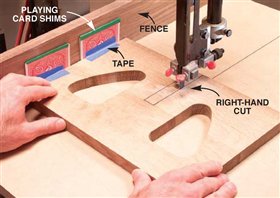

1.Make two shims equal to

the width of your bandsaw

blade’s kerf (Photo 3). Tape

the shims together in a

package.

2. Lay out the half-lap joints

on both rails (Fig.C,page 61).

3.Mark one notch anywhere

on test piece F.Cut the notch

as described in Steps 4

through 7 and test the fit

with an uncut rail.

4.Tape the shims to the end

of the rail so they slide along

with it.Be sure the shims are

snugged up against the

fence. Make the right-hand

cut all the way to the bottom

of the notch (Photo 4).

Remove the shims and insert

spacer G.

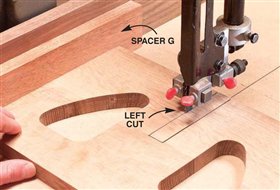

5. Make the left-hand cut

(Photo 5).When cutting the

actual pieces, repeat steps 4

and 5 with the second rail.

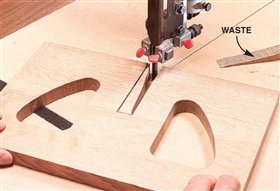

6.Move the fence away from

the blade and clean out the

waste between the saw cuts

(Photo 6).

7.Test fit the notch on piece

F. If the joint is too loose,

add another paper shim. If

the joint is too tight, reduce

the thickness of both shims.

When satisfied, cut the real

joints.

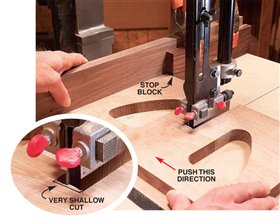

8. Cut the bottom of the

notch by nibbling away at it

with your saw blade (Photo

7). Reset the angle on the

fence so it is parallel to the

blade, but don’t clamp the

fence in place.With the saw

turned off, advance the rail

into the saw blade so the

blade comes right to the

bottom of the notch.Clamp

a stop block to the fence

against the top of the rail.

Now, back the rail out a bit,

turn on the saw, and nibble

off the bottom of the notch

by moving the fence from

right to left. Make very

shallow cuts. After a few

passes, you’ll have a perfectly

square bottom. You could

finish off the notch with a

chisel or file, but nibbling

with a bandsaw goes much

faster.

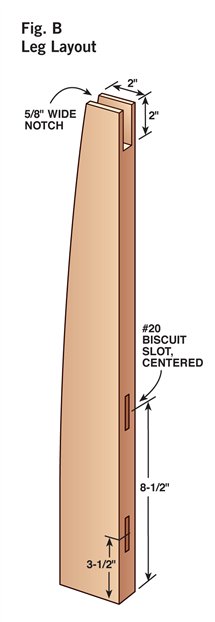

Make the legs

Select the wood for the legs

(see Choosing Wood for the

Legs).

1. Plane the legs (B) to

thickness, saw to full width

and crosscut to length.

Attach a taller fence board

to the miter gauge. Set the

bandsaw for drift with a

scrap piece that’s the same

width as the legs.

2. Draw the bridle joint

notches (Fig. B).

Each notch must be dead

center, but its precise width

isn’t critical.The surefire way

to center the cut is to saw the

notch from both sides of the

legs, without moving the

fence (Photo 8). Clamp a

stop block to the fence so

the cut stops at the bottom of

the notch. Saw the outside

cuts, then remove most of

the waste, as you did with

the rails above.

3.Take the drift angle out of the fence. Unclamp the fence

and square the bottom of the

notches by sliding the fence

right to left.

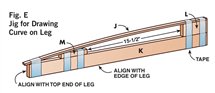

4. Trace a curve on the legs

with a jig (Photo 9 and Fig.

E). Align the

straight side of the jig with

the edge of the leg. Saw the

legs on the bandsaw and

smooth the curve with a

sander, rasp or hand plane.

Fit the upper rails

1. Plane the upper rails (C)

to fit the leg notches (Photo

10).Cut spacer H from a 12-

in.-long board planed to the

same thickness as the rails.

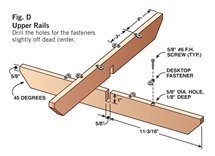

2. Layout notches on both

rails (Fig. D). Cut

the notches by a similar

spacing system as above.

This time you don’t need the

auxiliary table, however.

First, tape a shim to the right

end of the rail and line up

the blade with the left

marking line. Clamp a stop

block against the shim and

make the cut. Stop at the

bottom of the cut and clamp

a second stop block to the

table. Remove the shim,

insert spacer H and make the right-hand cut (Photo

11). Remove the waste and

clean out the bottom by

sliding the rail right to left

along the fence.

3.Angle the ends of each rail

(Fig.D).

4. Drill shallow holes in the

upper and lower rails (Figs.C

and D) for figureeight

desktop fasteners (see

Sources). Install all

the fasteners.

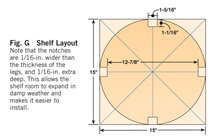

Construct the shelf and top

1.Glue up the shelf blank (D).

Lay out the notches and

circular edge (Fig.G,page 61).

2. Cut the notches on the

bandsaw (Photo 12).You can

simply reset the fence to cut

both sides of each notch,

rather than use shims and

spacers, because the exact fit

isn’t critical.

3.Cut the shelf’s circular edge

using a brad as a pivot pin.

Set the brad 7-1/2 in.

perpendicular from the front

of the bandsaw blade and

snip off the head (see

Versatile Bandsaw Table).Mark dead center on the

underside of the shelf and

drill a 1/16-in. hole for the

pivot pin. Set the shelf on top

of the pin, placing the blade

within one of the notches

(Photo 13). Rotate the shelf

on the pin, and you’ll cut a

perfect circle (Photo 14).

4. Glue up the top (A).

Bandsaw its circular edge

freehand.

5. Round over the edges of

all the pieces except the upper

rails. Use a 1/8-in. radius bit

in a hand-held router or a

router table. Round over the

inside corners of the shelf ’s

notches with a chisel or file.

Sand all the parts to 220 grit.

Join the legs

and lower rails

1. Cut biscuit slots for the

lower rails and legs (Photo

15). Be sure the slots are

exactly centered.

2. Glue two legs to a lower

rail (Photo 16). Make sure

the ends of the legs, a spacer

and the rail all fit tight

against a straight board

clamped to your bench.Glue

the other rail and the second

set of legs, too.

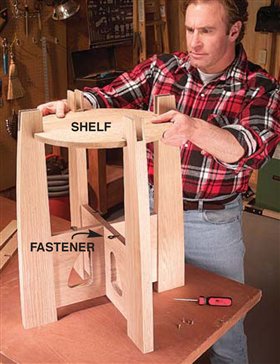

Assemble the table

1. Glue together the lower

rail and leg assemblies on a

flat surface (Photo 17).

2. Slide the shelf down on

top of the rails (Photo 18). If the shelf is too

tight, trim the notches with a

chisel or on the bandsaw.

Screw the shelf to the

fasteners.

3. Test the fit of both upper

rails without glue. Glue the

rail that has the notch facing

up first (Photo 19).

Once it’s positioned,glue the

other rail. Sand the bottom

edges of both rails.

4.Center the top and attach

it to the fasteners.

Finish

Many commercial stains

look good on oak, but we

went a step further. We

colored the raw wood with

golden oak dye, sealed it

with shellac and applied a

glaze made of equal parts of

raw sienna and raw umber

pigments.

Finally, we brushed on

two coats of varnish.

Sources

(Note: Product availability and costs are subject to change since original publication date.)

Woodcraft Supply, woodcraft.com, 800-225-1153,

1/2" 4 tpi bandsaw blades, various

lengths;

1" Forstner bit, #125935;

1-1/4" Forstner bit, #125937.

West Penn Hardwoods, westpennhardwoods.com, 888-636-9663, Quartersawn White Oak, 4/4.

Woodworker’s Hardware, wwhardware.com, 800-383-0130, Desktop fasteners and screws

KV1547.

*** Blick Art Materials, dickblick.com, 800-828-4548, Raw Sienna artist’s oil,

#00461-8063; Raw Umber artist’s oil,

#00461-8073; Liquin glazing medium

#00445-1004.

Woodworker’s Supply, woodworker.com, 800-645-9292,

W1100 Light golden oak dye.

Cutting List

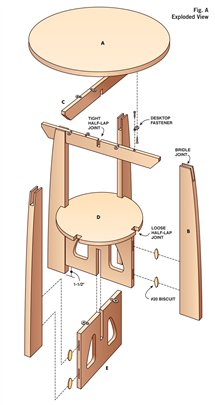

Fig. A: Exploded View

Fig. B: Leg Layout

Fig. C: Lower Rail Layout

Fig. D: Upper Rails

Fig. E: Jig for Drawing Curve on Leg

Fig. F: Lower Rail Template

Fig. G: Shelf Layout

This story originally appeared in American Woodworker September 2003, issue #102.

September 2003, issue #102

Purchase this back issue.

|

|

Click any image to view a larger version.

1. Rough cut

the openings in

the lower rails. Drill

large holes in the

corners, then

connect the holes.

Stay 1/16-in. off

the line.

2. Cut the rail’s

final shape with

a template and

router table. Fasten

the template to the

rail with doublefaced

tape.Move

the rail and template

counterclockwise

around the

router bit.

3. To prepare for

cutting the half-lap

joints, make shims that

fit exactly into the kerf of

your bandsaw blade.The

width of a kerf varies from

blade to blade.This one equals

three playing cards and one sheet

of paper.

4. Saw the right side of

the half-lap joint using

the bandsaw table. Tape the

playing-card shims to the

end of the rail. Position and

clamp the fence so the

blade lines up with the

right-hand marking line.

5. Saw the left side.

Replace the shims with

a spacer that’s the same

thickness as the rail you’re

sawing.Without moving the

fence, you’ve made a

perfectly fitting half-lap

notch.The space between

the cuts is exactly the

thickness of the rail.

6. Remove the waste

with several diagonal

cuts. Unclamp and slide the

fence out of the way. Keep

cutting until all that’s left is

1/16 in. of wood above the

bottom of the notch.

7. Trim the

bottom of the

notch by cutting

sideways. Remove the

clamp from the fence.

The miter-gauge can

now slide in its slot, so

you can move the

fence and rail as a unit.

Nibble off about 1/64-

in. per pass (see inset).

The result is a

perfectly straight and

square bottom.

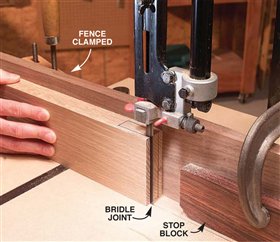

8. Saw bridle joints

in the top of the

legs with the bandsaw

table and fence.To

center the notch, saw

one side first, then flip

over the leg and saw

the other side. Clean

out the waste and trim

the bottom the same

way you did for the

rails above.

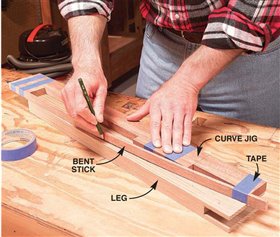

9. Draw the

curve on each

leg with a bent-stick

jig.Tape holds the

bent stick to the jig,

freeing your hands to

draw a smooth curve

(Fig. E).

10. Test fit the

upper rails to

the legs. Plane each rail

until it’s one sheet of

paper thinner than the

notch in the leg. If the

fit is too tight, you’ll

have a hard time

pushing the rail down

into the notch at glueup

time.

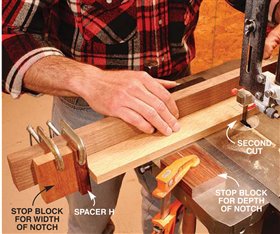

11. Cut notches in

the upper rails.

The cutting process is

identical to making the

joints on the lower

rails, using the same

shims but a new

spacer.This time you

use the miter gauge in

the standard slot on

the bandsaw table.

Choosing Wood for the Legs

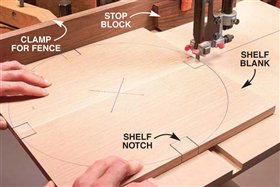

12. Saw the shelf

notches while the

shelf blank is still square.

Back on the bandsaw

table, cut all the right

sides with one fence

setting.Then move the

fence and cut all the left

sides. Nibble the bottoms

square.

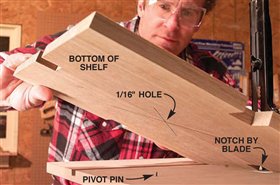

13. Position the

shelf on a pivot

pin. It’s just a brad driven

into the bandsaw table.

Snip off the head of the

brad and align it with a

small hole drilled in the

center of the shelf.

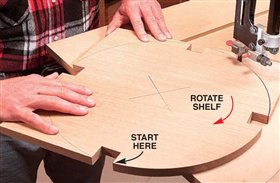

14. Rotate the

shelf on the

pivot pin to cut an

exact circle. Start the

cut inside one of the

notches.

15. Cut biscuit slots

in the legs. If you

don’t have a plate joiner,

you could use 3/8-in.

dowels or make 1/4-in.-

thick loose mortise-andtenon

joints.

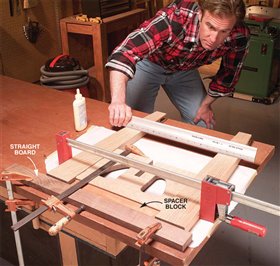

16. Glue together the lower rail and legs. Clamp a 1-1/2-in.-wide spacer between the rail

and a long, straight board to align the joints. Check for flatness to ensure that the

upper rails will fit across both notches.

Oops!

17. Slide one half of the table down

over the other to glue them

together. Clamping is not necessary.

18. Drop the shelf down onto the rails.

The notches are slightly oversize to

make this easier. Screw the shelf to the rails

with desktop fasteners to stiffen the whole

assembly.

19. Glue one rail at a time.Apply glue

to the rail that has the notch facing

up and set it in the legs. Before clamping,

insert the other rail without glue.This

ensures the first rail is properly aligned.

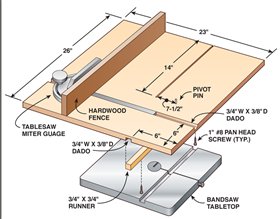

Versatile Bandsaw Table

In less than an hour,

you can upgrade your

bandsaw with a larger

work surface, a rip

fence and a circlecutting

jig.All it takes

is three pieces of

wood.

Make the Table

This is really easy. Cut a piece of MDF or plywood to size. Use a router or

tablesaw to dado one groove on the top and one on the bottom. Glue a

runner into the bottom groove (you can use an offcut from the top).Turn

on your bandsaw and slide the table into the blade, stopping about in the

center. Install two screws under the runner to act as stops, keeping the

table from moving.To remove the table, tilt up the far end and pull back.

Adjust the Fence

Attach any straight board to the face of your

miter gauge, and you’re set to go.The fence has to

be angled a little bit to compensate for the “drift”

of the blade, and that angle varies with each blade

and thickness of wood you’re cutting.

To adjust the miter gauge fence for drift, draw a

straight line on a board parallel to one edge. Saw

freehand, angling the board to stay on the line.

Stop halfway, turn off the saw and clamp the

board. Loosen the miter gauge and push the fence

up against the board.Tighten the miter gauge,

remove the board and you’re ready to saw.

|