We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

20 Finishing Tips

Purchase the complete version of this woodworking technique story from AWBookstore.com.

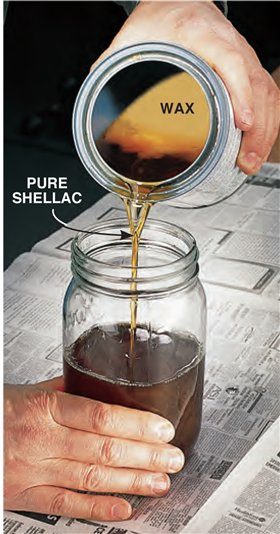

Make dewaxed shellac

Take the wax out of shellac and you have a great sealer that’s

compatible with most other finishes. It’s best to get this “dewaxed”

shellac as dry flakes that you mix with denatured alcohol.

Usually you have to order the flakes through the mail. But in a

pinch, you can decant (draw off one layer of liquid from another) dewaxed shellac

from the canned shellac you’ll find at the hardware store.

Bring a clean can or lidded jar with you to the store. With the okay of a salesperson,

carefully carry a can of shellac to the counter and open it. If the liquid

looks creamy, like cappuccino, put the can back and try another one. A good

candidate for decanting will contain a clear, deep amber-colored liquid with a

creamy-colored layer of residue

at the bottom. This indicates that

the wax has settled out. You can

decant between two and three

cups of dewaxed shellac from

a quart of liquid shellac. After

decanting, pay for the shellac and

ask the clerk to dispose of the

can with the waxy residue.

|

|

Click any image to view a larger version.

Decant dewaxed

shellac from a can

at the hardware

store. Find a can

in which the wax

has settled to the

bottom and pour

off the pure shellac

from the top.

|

|

Thin the decanted

shellac with an

equal amount of

denatured alcohol

for use as a sealer.

|

|

|

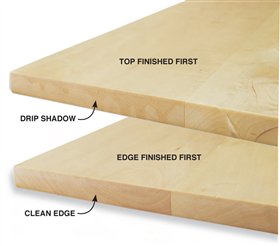

Eliminate drip shadows

When finishing a large flat surface, the temptation

is to finish the top first. Inevitably, some

varnish runs over the edge and soaks into the end

grain. Even after you finish the edge, the soakedin

drips remain as dark shadows. No amount of

re-coating takes care of it and you’re faced with

having to strip, sand and refinish.

Fortunately, the problem is easily avoided. Coat

the end grain with a thinned coat of varnish before

tackling the top. A mixture of two parts varnish

to one part mineral spirits works well. The drips

won’t be able to soak in and leave their shadow.

|

|

|

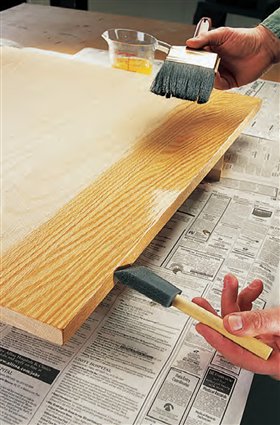

Use two brushes to control drips

A big brush that holds a lot of finish is great for covering a large flat surface. But that same big brush

often leaves too much finish on its thin front edge. The remedy: use two brushes. First, using the big

brush, quickly cover the front edge and an adjacent section of the top with finish. Tip off this swath of

finish on the top with the big brush. Then switch to a second smaller brush and smooth out the coat

on the edge, removing any sags and drips as you go. Once the edge is finished, switch back to the big

brush, feather in where you left off and finish the top.

|

|

Drips and sags on the front edge of a board are hard

to clean up with a big brush because it leaves a

heavy coat that’s likely to sag.

|

|

Use a second brush—small, disposable foam

ones work great—to get rid of drips and sags

on edges. The secret is to keep this second

brush fairly dry—only dampened with mineral

spirits—so it can wick up excess finish. Hold

this brush at an angle so it cradles the bottom

lip of the edge and make one long end-to-end

stroke. If you need to make a second pass, put

on a plastic glove and squeeze out the brush.

|

|

|

Test finishes on hidden areas

Here’s one of the best (and most ignored)

tips for getting a great finish: test the stain

colors and topcoats you’re considering for your

masterpiece on its hidden areas. If your piece

has no unseen surfaces, use offcuts from the

project or leftover scraps of the same wood.

Prepare the areas for your hidden tests

as diligently as the parts that show.

Record your finishing procedures for

each sample. Be sure to topcoat stains

and dyes—they usually look totally different

under a finish. Aerosol cans of

shellac or lacquer work great for this.

Be sure to look at your samples under

the kind of light the piece will live in—

finishes look different under natural or

incandescent light than they do under

fluorescent shop lights.

|

|

|

Make surface checks disappear

Don’t let small surface checks keep you from using an

otherwise good board. Got a minute? You can make those

checks disappear.

Squeeze cyanoacrylate (CA) glue into the crack. CA glue

works better than yellow glue because it dries very quickly.

Any brand of gap-filling CA glue with a 5- to 15-second open

time will work. Use a tip with a pin-sized hole (you

can get replacement tips for 50 cents at hobby

stores).

Immediately sand the area, mixing sanding dust

with the glue and packing it

in the cavity. Keep sanding

until the crack is filled and the

excess glue is removed.

You may need to repeat the

process. Under a finish, the

sanding dust/glue mixture is

almost invisible.

|

|

|

Product Recommendations

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.