We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

by Eric Smith

People give me strange looks when I tell them I don’t mind sanding. Yeah, it’s dusty and a bit tedious, but I enjoy watching the fine detail in the wood grain pop out as I go through the grit sequence. That silky smooth surface reminds me why I became a woodworker. I also look at sanding as my best opportunity to catch potential finishing problems before they blossom into complete disasters. Even so, I like to sand efficiently and get good results for my time. I’ve learned some simple techniques over the years that can keep you from spending more time at the job than necessary. Here’s a sampling.

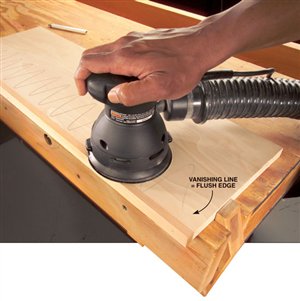

Pencil Lines Tell You When To Stop

There’s nothing worse than sanding right through a veneer. Pencils lines are a great way to gauge sanding progress. I always draw lines on plywood where it meets a solid hardwood edge. The lines will start to disappear when the hardwood edge is flush with the plywood. That’s when you know it’s time to stop.

Pencil lines work on glued-up boards, too. The boards aren’t even until all the lines are gone.

|

Dust Collection Improves Sander Performance

Without dust collection, your sander rides on a layer of sawdust, greatly reducing its effectiveness. With a shop vacuum hooked up to your sander, excess sanding dust and grit particles are vacuumed up instantly. This ensures complete contact between the paper and the wood at all times allowing your sander to work at maximum potential. Plus, the lack of dust and grit helps keep you, your shop and your lungs clean.

|

Scrapers Leave Sanders in the Dust

Scrapers have been around for centuries, and for good reason: They do the job fast! A sharp scraper leaves hardwoods with a smooth finish that only needs a little finish sanding. A scraper is faster than an orbital sander and you never have to change grits. The hard part is getting a good cutting edge on a scraper; it takes some practice. But, once you’ve used a sharp scraper, you’ll find yourself reaching for it more often than for your sander. (For more on sharpening a scraper, see AW #102, September 2003, “Foolproof Scraper Sharpening”.)

|

Keep Edges Crisp

Lay pieces of scrap wood of equal thickness to bridge the piece you’re sanding. This will prevent the sander from tipping and rounding over the crisp edges.

For sanding the narrow edges of doors, clamp the door between two pieces of thick stock to help steady the sander.

|

Skip Grits

Really, it’s OK. We checked with several major sandpaper manufacturers and each one said the same thing: Whatever grit you start with, you can skip every other grit as you progress from coarse to fine. Using each grit in sequence is almost always overkill, not to mention extremely tedious. If you start at 100, skip to 150, then 220. Or from 80, go to 120 and then 180.

|

Pipe Insulation Contour Sander

Sticky-backed sandpaper and foam pipe insulation team up to make perfect custom contour sanders. The flexible pipe insulation can be rolled to conform to almost any size of curve.

|

Coarse Grit Saves Time

If you need to remove a lot of material, using too fine a grit is a waste of time and paper. Use 80- to 100-grit sandpaper to do the hard, time-consuming work. As a rule of thumb, you should spend about 80 percent

of your time with these coarser grits. Then the finer grits simply remove scratch marks from the previous grit.

|

Flap Sanders Eat Wood

A flap-sanding disc turns an angle grinder into a great tool for shaping and sculpting wood. You’ll be amazed at how quickly these things remove wood. Be sure to take time to practice a bit before you scoop out your first chair seat.

|

Soft Pads Increase Random-Orbit Sanders’ Flexibility

A soft replacement pad does a better job than the standard firm pad that comes with your random-orbit sander when it comes to sanding contoured areas.

The thick, flexible pad conforms to a soft curve. A stiff pad tends to dig in and ruin the work.

|

Hold Wood Steady with a No-Slip Pad

Router pads do a great job of gripping flat pieces of wood during sanding. With a router pad, you don’t need to stop and move clamps around or (one of my personal bad habits) try to hang on to a board with your fingertips and work the sander one-handed.

|

A Raking Light Finds Hidden Defects

Shine a bright light from different angles across sanded boards to illuminate hard-to-see swirl marks and problem spots while they’re still easy to fix. Use the light before each grit change and you’ll avoid having to back up several grit levels to remove a deep scratch.

|

Dampen the Wood for a Clean, Smooth Finish

After your final pass with the power sander, wipe a damp sponge over the wood. As the wood dries, any loose wood fibers will stand up.

Let the wood dry completely. Then lightly sand the whole surface with 220 or higher grit paper to knock off the whiskers. This yields as smooth a wood surface as you can get and is especially important when you use water-based finishes that tend to raise the grain anyway.

Wetting the wood will also reveal any hidden glue smears or sweat drips. Or you can wait until the varnish is on to see them—your choice.

|

This story originally appeared in American Woodworker October 2004, issue #110.

Source information may have changed since the original publication date.

Source

Highland Hardware (800) 241-6748, www.highlandhardware.com BAHCO 474 card scraper, #031509, $6. Hardware stores and home centers, pipe insulation, $2 per 4-ft. length. Home centers and hardware stores, 3M flap-sanding disc, $9, angle grinder adapter $10. Check the supplier of your sander; pads vary with brand and model, $15 to $25. Home centers and hardware stores, router pad, $7.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.