We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Rob in 1991

Editor’s Note: Back when we began putting the 40th-anniversary timeline together, we reached out to some of our previous editors with a few questions of what PW meant to them. Rob Cook, editor from 1992-1994, said “your questions brought back a lot of memories when I had your job.” Little did we know that we were going to get a full story back that keep us intrigued the entire article

What in your mind made/makes PW different than other magazines?

A little history. I left my position as a financial consultant of 15 years at the beginning of the first Gulf War in January, 1991. I did a bit of antique repair for some of the dealers in my town until the recession killed it off five months later.

So it was time to get a real job again. I found a listing in the local paper for a woodworking writer. That sounded interesting—I’d always loved working with my hands and I thought I’d learned to write in college. So I took a writing sample and a couple of project photos with me. The interview was with Wayne Lin, the owner of EGW Publishing and David Camp, the editor of PW. Wayne had started Pacific Woodworker with David and as the editor some eight or nine years earlier. (It may have been a different editor at first, but you’d have to check). Wayne also owned a couple other craft magazines. At the time, David was in his late 20s, I was in my early 40s. He was quiet and reserved, I was outgoing and talkative with a lot more life experience—I respected his talent with words, and he my woodworking talent.

I was hired as an assistant editor and taught how to write in the active voice (my degree is in zoology not journalism). After a couple of months—and a few fun builds later, Shop Manager was added to my title as Assistant Editor on the masthead.

Back then publishing was an analog world. We edited and laid out text in PageMaker and placed FPOs from our little Epson scanner on a Mac II SIs with 1 meg of RAM. We sent out for Linotype, waxed art boards, cut rubylith with an x-acto knife, listed the CMYK colors for type and then mailed it all off to the strippers, then on to the printer. (Two years later, when PW was sold to F&W Publications, I was producing the magazine 100% on the desktop—we had no separate Art Department.)

After a little over a year on the job, David, a vegan, was tasked with starting a vegetarian magazine called Veggie Life. The ranking associate editor of PW didn’t want the responsibility as editor of PW so I was it. I was already on my way to becoming a fairly decent writer, but now it was time to refine my design chops.

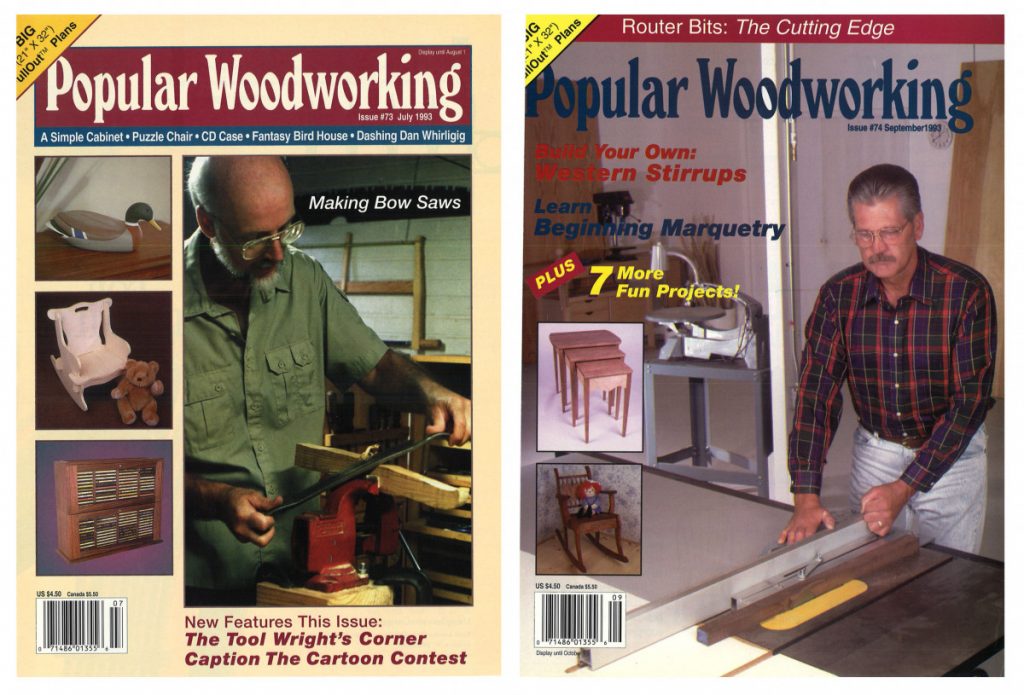

Ben, the editor of Weekend Woodcrafts (a sister pub started after I joined) was a really talented designer. He would help me with laying out a couple of articles when I was on deadline, and I him. Together we undertook to redesign the whole of PW, cover to cover, because we thought it was time for a face lift. We took our finished product to Wayne for approval and all he wanted to see was the cover—which was all he seemed to care about because that’s what drove news stand sales and subscriptions! That was when we went to a full-bleed cover featuring our “big” article glamour shot. He liked it.

The old (left) and new cover designs in 1993.

I was allowed to buy, commission or build what I liked—we paid $125 a published page. One of the perks we had was that we were allowed to keep what we built since we didn’t get the price per page. Ad sales determined how many pages I had to work with, but I had to make it all fit in 100 pages.

Every year at the National Woodworking Show in Chicago, the other editors and I would always manage to get together and share a few shop stories, gossip about some of our shared authors, bitch about our publishers and compliment each other on articles that we wished we had published. My last year there they all cornered me and wanted to know who my publisher used to do demographics. I had taken subscriptions from 180,000 to a little over 280,000 in a year and a half. I told them I just did what I liked. Now I have to admit that I don’t know if it was just the times or me, but it was the most fun thing I’ve ever done for money in civilian life. (I was a Cobra gunship pilot in Vietnam—the flying part was also pretty fun!)

Anyway, with those subscription numbers, F&W came calling and Wayne gave it up for a rumored $2.5 million. F&W flew me out for an interview. First stop, an industrial psychologist—give me a break! Next, a staff meeting with all the department heads. When asked what I would require to produce the magazine I told them that if they gave me two good woodworking writers I’d give them files ready for film. Needless to say, the art director went ballistic. They ended up going with someone else and after producing their first issue from California, I went on my way.

So yes, we went about it from a different direction than traditional publications, but what a ride. David impressed on me that words on a page were a picture too. I would have stayed until I was 65 or even later if Wayne hadn’t sold it.

What do you think one of the most Iconic PWW projects over the last 40 years have been?

After leaving Popular Woodworking and not getting picked up by F&W, I needed to move on—my wife and I had five daughters to raise. I did sell one article to another woodworking magazine, but pretty much gave up woodworking, except for a few things around the house, until last year, but that’s another story. I occasionally picked up a copy of PW in my local bookstore just to see how they were doing, but that’s about all. So, all I can talk about was the time I was there.

Hands down, my favorite articles and projects were ones by Ken Sadler. Ken was in his mid to late 60s when I took over the magazine and had been a regular contributor for several years. Ken was a custom furniture builder by trade and lived in the Pacific Northwest on his own plot of forest—read lumber supply, walnut, ash, alder and beech. This was a woodworker that could sell a rocking chair for $1000 back in the 1970s. I got to sit in one and my back just melted into the spindles.

Download a Ken Sadler chair project from the May 1991 issue.

Ken had made me an offer I couldn’t refuse. He had become allergic to walnut (wear a mask my fellow kings and queens of sawdust) and asked me if I wanted his lumber supply. Hell yes! All I had to do was convince Wayne how much money he could save in local lumber costs for the price of two airline tickets and a U-Haul rental. He went for it and we drove home with a truck full of 2” x 10-12” x 14′ slabs and pieces of good, dry lumber. A lot of the alder was beautifully spalted. (That’s when I got to sit in one of his rockers.) I took most of it with me when the magazine was sold.

He was also a talented writer. All I needed to do with his articles was edit for style and occasionally correct for voice. Most of the time there was just a just a finished photo that came with the text, so we got to build his creations in our shop.

I really respected the man. In one conversation before I became editor, he chewed me out for over-editing an article he’d written. He told me to go back and read what he’d originally written, then read my version and call him back and explain why mine was better. I did, and I couldn’t. I think he probably told David that he didn’t need to fire me!

Ken became my woodworking dad—my real dad thought a screw driver was something with orange juice in it, not mechanical at all.

Check out Ken’s book here [Amazon]

What, in your mind, is the biggest change in woodworking in the past 40 years?

Getting back into woodworking after 30 some odd years has been an interesting adventure. Going from a few bench-top tools to a cabinet saw, a bandsaw with a 13” throat, a three-bladed planer and a variable speed, reversible lathe was an expensive undertaking over the last year—never mind what I spent on jigs and fixtures.

Record had given us a lathe at PW I was immediately drawn to it. Wayne let me take it with me when I left. I did very little with it over the next 30 years until a neighbor asked me to build a six foot, two leaf dining table with turned legs.

Then I discovered epoxy use in turning. Haven’t done it yet, but I donated that old Record to a local church with a big woodworking shop and bought a new Laguna. Now if I can only find time to use it. Other projects keep getting in the way!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.