We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

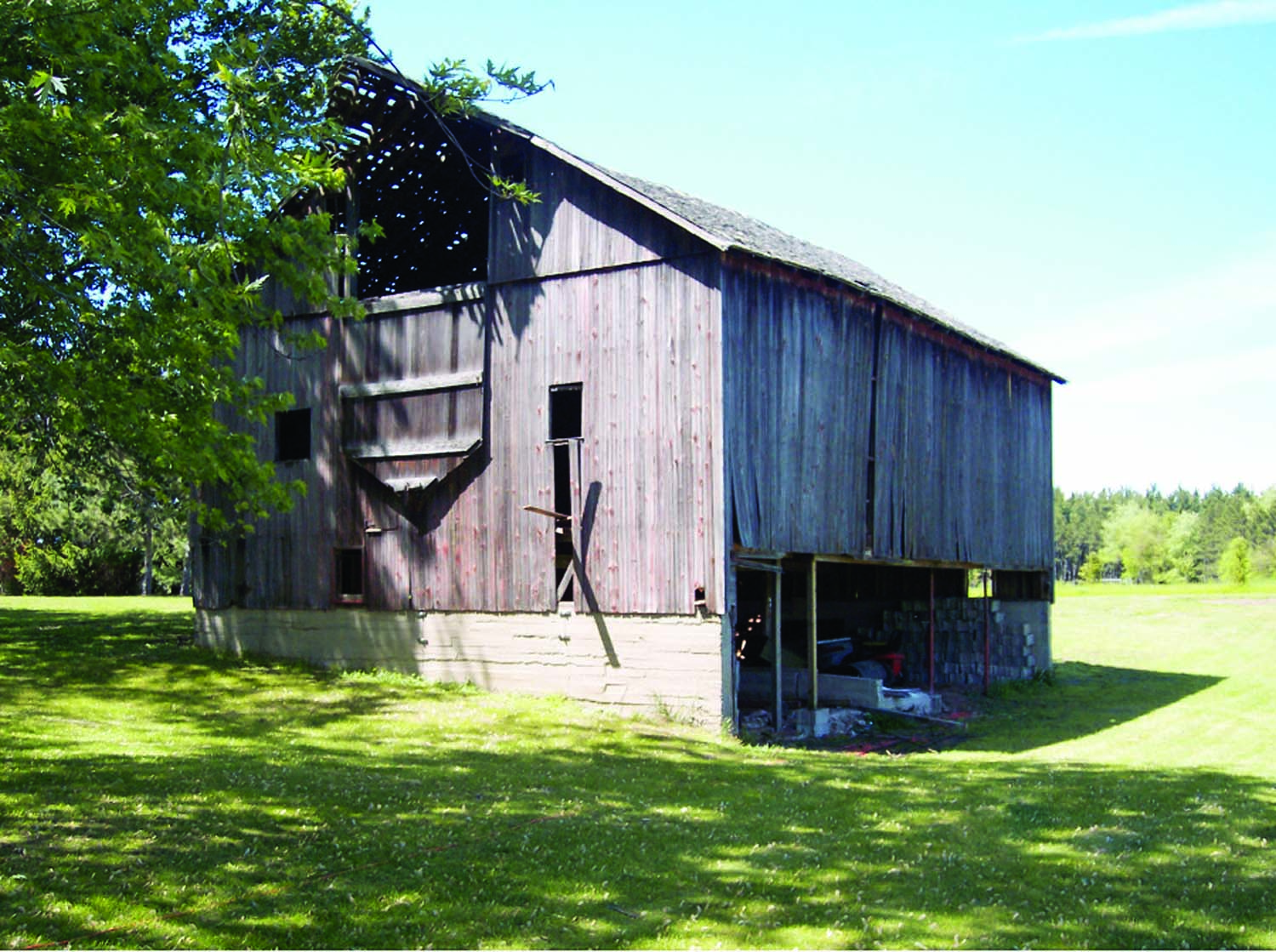

My wife and I bought a 100-year-old farmhouse near Bristol Indiana that came with a decrepit 30′ x 40′ barn. I planned to save the barn after we finished restoring the house. However, plans don’t always work out. A couple years later I was facing my second knee replacement and knew I wouldn’t be able to return to my job as a pattern maker.

While recovering from the surgery, I decided to start my own woodworking business and turn the barn into a wood shop. This would be my second shop. I lost my first in a fire 25 years ago. At that time, I couldn’t afford to bring it back.

I read every woodworking magazine I could find to get up to date on all the advances in machinery that had occurred since my first shop and used this information to create a list of the machines I’d need for my new shop. I intended to use the barn’s lower level to conduct craft classes. That left the 20′ tall upper level for the shop. In the layout I planned, there’d be room for all the new machinery, but no space for a dust-free finish area. Suddenly, the 20′ ceiling became two 10′ ceilings, with a finishing room and a storage area located above the main shop.

Now, how to get pieces to the finishing room? Stairs were out of the question, so an elevator became part of my plan: I’d cut a hole in the ceiling and use an electric hoist to raise and lower an open-framed box.

By this time I was ready for therapy on my new knee—restoring the barn provided that therapy. First I had to address its walls, which had listed under the sagging roof. I strung cables around the perimeter and slowly pulled in the walls a little each day. It took weeks but eventually they were straight and the roof—what was left of it, anyway—was lifted back to its intended position.

Rebuilding the floor was next. Knowing it would have to support a great deal of weight, I sistered 2x12s to every joist, using carriage bolts every 16″, and installed new support beams in the basement. Then I triple-decked the floor, staggering every joint. To leave a clear span in the main shop area, I installed 30′ wooden I-joists and a single-deck floor to create the upper finishing room/storage area.

The barn’s exterior required a great deal of work, as I added windows, a walk-in door and a large double door, not to mention the 57 gallons of paint it took to refresh the thirsty weathered siding. To provide additional support and space for insulation, I built sister walls inside all the exterior walls. The roof received the same treatment, with I-joists sistered to the old rafters.

I installed a furnace in the basement with ductwork to the main level and added a new sub-panel box, with conduit runs in the floor joists to all the machinery and to outlets around the shop’s perimeter. I installed phone and computer connections and industrial fluorescent lights. I ran water lines and installed laundry sinks on both levels. Except for the new metal roof, the concrete basement floor and a little help from friends and family at critical times, I did all the work myself.

Then, while helping to unload my new machinery, the 800 lb. compressor fell on me. The accident resulted in permanent nerve damage that has caused me to lose partial use of my legs. Still, I’ve managed to set up the shop and continue to work as I can on a daily basis. I’ve installed heavy-duty casters on a chair that I use to scoot around from machine to machine. My dream of a profitable woodworking business is gone, as I can no longer work fast enough to do any better than breaking even. But I do what I can. I’ve created a growing line of doll furniture—mostly solid oak—that I market online and I happily build items for friends and family members. As I said at the beginning, plans don’t always work out. You just gotta go with the flow.

Deni Madlem

Bristol, Ind.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

The title of this article caught my eye. It is a very inspiring story especially since as a hobbist woodworker I also battle chronic pain from 25 years of rheumatoid arthritis. Initially I was shocked and saddened by your 800lb compressor accident. However, you positivity even in adversity is extremely encouraging. Well done Deni continue enjoying your craft. Blessings.