We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Woodworking with all the comforts of home.

One glance in my shop reveals an unusual device—a reclining chair. But don’t get the wrong idea; things do get done here. It’s just that my 70-year-old back isn’t what it used to be and occasionally I need to sit down, put up my feet and catch a few minutes of the ball game.

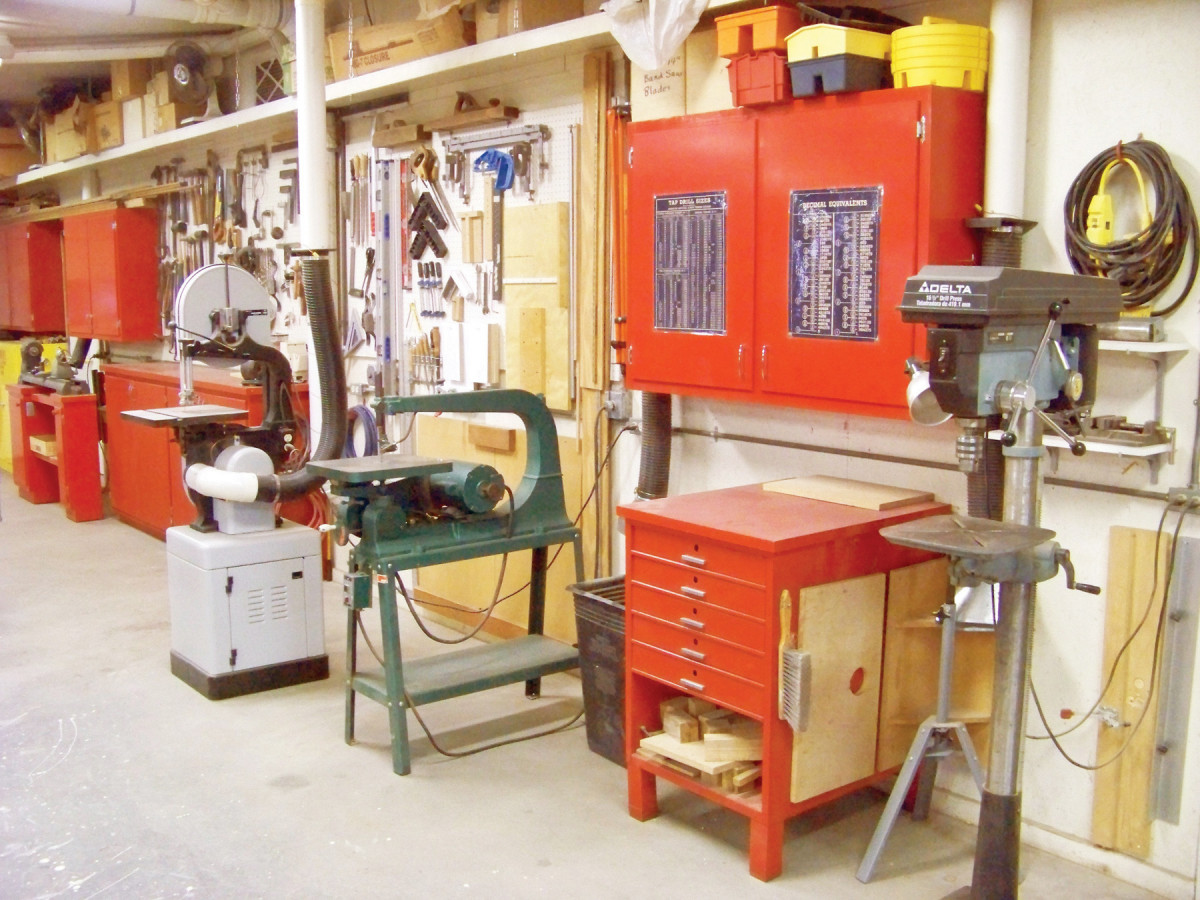

I built this shop years ago while I was still teaching here in Rose Hill, Kansas, by carving out time on evenings and weekends. The main part is 36′ x 60′ with a 16′ x 60′ lean-to storage addition. It has 6″ thick walls, a 10′ ceiling and is heavily insulated. The walls and ceiling are covered with oriented strand board, so I can mount cabinets, shelves, conduit, etc., just about anywhere. All the shop cabinets are made from salvaged scrap materials. It’s amazing how a coat of red paint hides the imperfections and blends the assorted woods.

I built this shop years ago while I was still teaching here in Rose Hill, Kansas, by carving out time on evenings and weekends. The main part is 36′ x 60′ with a 16′ x 60′ lean-to storage addition. It has 6″ thick walls, a 10′ ceiling and is heavily insulated. The walls and ceiling are covered with oriented strand board, so I can mount cabinets, shelves, conduit, etc., just about anywhere. All the shop cabinets are made from salvaged scrap materials. It’s amazing how a coat of red paint hides the imperfections and blends the assorted woods.

Besides the chair and TV, the shop has other creature comforts, including a bathroom with a built-in double sink and hot and cold running water. A refrigerator and a microwave oven reside in the office, so I can fix a snack whenever hunger strikes. The office also houses a drafting table and a drafting machine. A phone with a flashing strobe light and an amplified ringer, and a wireless intercom to the house keep me in touch with the world outside.

Another room is equipped for spray finishing, with a filtered exhaust fan and explosion-proof lights. When the exhaust fan is running, four filters housed in the room’s double entry doors scrub the incoming air, to keep out the dust from the main shop.

Another room is equipped for spray finishing, with a filtered exhaust fan and explosion-proof lights. When the exhaust fan is running, four filters housed in the room’s double entry doors scrub the incoming air, to keep out the dust from the main shop.

Eighteen commercial fluorescent light fixtures illuminate the shop. I rewired each fixture so one, two or three bulbs can be turned on as necessary, to provide sufficient light.

Eighteen commercial fluorescent light fixtures illuminate the shop. I rewired each fixture so one, two or three bulbs can be turned on as necessary, to provide sufficient light.

The shop’s 1,200 cfm dust collector is located in a small, insulated room in the lean-to, so the noise stays at reasonable levels. The dust-collection lines are made of PVC drain pipe and grounded with copper wire. Air drawn through the collector returns to the shop through a pair of pleated filters.

My shop stays cool in the summer, thanks to all the insulation in the walls and ceiling. Five oscillating fans stationed side by side on a shelf provide a pleasant breeze, and a whole-house exhaust fan in the ceiling draws in fresh, cool air in the morning hours. In the winter, an overhead natural gas heater keeps things cozy. When the weather is cold, I park my truck in the shop, so I stay warm when I venture out in it.

You may be wondering about the tools! As you can see, I have a full line of stationary woodworking machines, portable power tools and hand tools. My industrial-tech teaching background shows in the layout. Each machine is logically placed for processing, with plenty of room to work. As I live on a farm, my shop also houses metalworking tools and machines that I’ve used to build several implements for my tractor and other farm equipment.

You may be wondering about the tools! As you can see, I have a full line of stationary woodworking machines, portable power tools and hand tools. My industrial-tech teaching background shows in the layout. Each machine is logically placed for processing, with plenty of room to work. As I live on a farm, my shop also houses metalworking tools and machines that I’ve used to build several implements for my tractor and other farm equipment.

I really enjoy working in my shop, especially when the weather is bad and I can’t do anything outside. I’ve built a lot of furniture over the years, so my tools and equipment have paid for themselves many times over. –Dennis Webster

Editor’s note: This article was originally published in American Woodworker #158

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.