We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Two days on the set of ‘The New Yankee Workshop’ reveal surprising truths about the way Norm Abram works.

Editor’s note: This article originally appeared in the August 2005 issue of Popular Woodworking

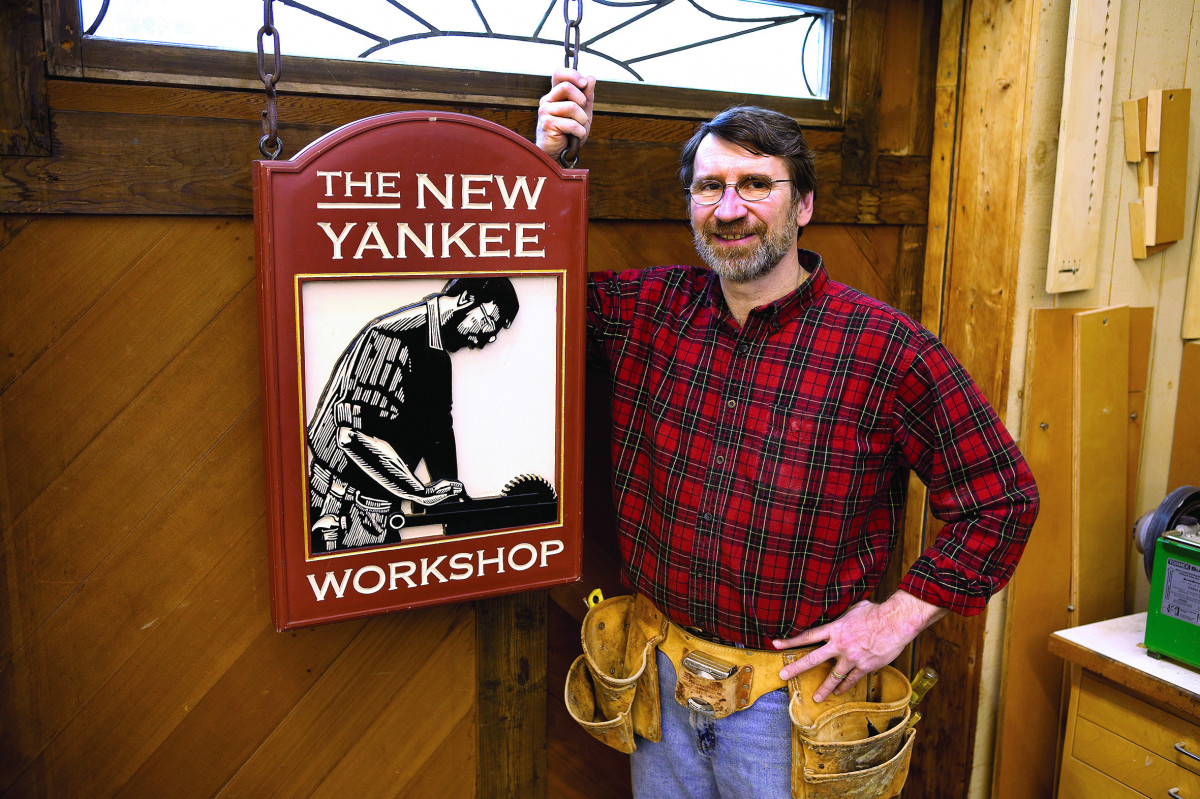

We’re lost. I’m trudging through two feet of snow in what looks to be someone’s backyard and there’s no sign of the image found on millions of woodworkers’ television screens every Saturday as they prepare for another half hour with Norm Abram. Where is the blue barn door? Where is the leaded glass window? Where is the iconic “The New Yankee Workshop” sign?

A few driveways and turnarounds later, just when I had decided that all of it – the shop, the sign, the setting – must be part of an elaborate set and therefore fake, we stumble on television’s most famous woodshop.

I can’t tell you the exact location of The New Yankee Workshop for two reasons. One, even with directions, I don’t know if I could find it again. Two, I promised to keep mum. But I will tell you this: None of it’s fake. What looks like the front of the shop on TV actually is in the back, to better hide its location. And if you slide that famous barn door open and step inside, you’ll find yourself in a very real, very normal, working woodshop.

Abram, host of the show, has received considerable flak and teasing for his remarkably well-equipped shop. But two days with Abram proved that there’s a lot more dust on this show’s set than glitter. Here, the legendary frugal Yankee blood runs deeper than you might think – Abram’s woodshop and practices are surprisingly normal.

The Birth of a Star Woodworker

The 36′ x 26′ saltbox-shaped shop doesn’t look like a TV set except for a few camera lights hung from the ceiling. At right you can see the back wall of the shop. The stairs lead to Executive Producer and Director Russell Morash’s office and a bathroom.

Abram is a celebrity. He’s recognized in airports, restaurants and grocery stores. He’s appeared as a guest on late-night television, afternoon talk shows and national morning news programs. His likeness has been featured on “Saturday Night Live” and “Home Improvement.” Fans have devoted web sites to him. His woodworking methods and cache of power tools are criticized as much as they’re coveted. A variation of his first name has become part of woodworking’s lexicon – “Normite” is Internet slang to describe someone who uses power tools only. Esquire magazine has called him the most famous carpenter of all time; excepting Jesus.

How did this happen?

The carpenter-turned-celebrity story begins more than 30 years ago when Abram spotted an ad for a carpentry job pinned to a bulletin board at the University of Massachusetts at Amherst. After spending two years working toward a mechanical engineering degree, Abram switched majors and was in his fifth year of college studying business administration. It was the early 1970s and office jobs were scarce. Within mere credits of earning his degree Abram got the carpentry job, quit school and moved to Vermont.

The carpenter-turned-celebrity story begins more than 30 years ago when Abram spotted an ad for a carpentry job pinned to a bulletin board at the University of Massachusetts at Amherst. After spending two years working toward a mechanical engineering degree, Abram switched majors and was in his fifth year of college studying business administration. It was the early 1970s and office jobs were scarce. Within mere credits of earning his degree Abram got the carpentry job, quit school and moved to Vermont.

By this time Abram was well-versed in carpentry. His summers during high school and college were spent remodeling and building custom homes with his father’s construction company. His carpentry skills and knowledge of business administration proved beneficial – he was quickly promoted to construction site supervisor. Not wanting to take the next promotion, which would have put him in an office-like environment, Abram founded a general contracting firm, called Integrated Structures Inc., in 1976.

One of his first contracting jobs was building a barn on Russell Morash’s property. During this time Morash, a producer and director for WGBH, was busy creating television’s first “how-to” home-improvement series, “This Old House.” Morash was impressed with Abram, his work and the small size of his scrap pile.

“He was quiet, effective, uncomplaining and met deadlines,” Morash says of Abram. “He was also unmarried and had no life,” Morash adds, laughing. So, in the winter of 1978, Morash invited Abram to help renovate the TV series’ first on-air project, a rundown Victorian in Boston’s historic Dorchester section. Abram agreed.

If you were to walk through the sliding barn door, this is what you would see to your left. Many of Abram’s machines are on mobile bases so they can be easily tucked into a corner when not in use.

Abram hoped his family members might catch him walking in the background, carrying a ladder. But he proved to be too good a carpenter. It wasn’t long before he was named master carpenter on the show and Morash attached a microphone to his flannel shirt.

“Norm was nervous as hell,” Morash says. “But he was good – credible, believable and compelling.”

Several years later, with “This Old House” still widely popular, Morash thought TV audiences also would be interested in a series on woodworking – hence, “The New Yankee Workshop.” But why would Morash choose Abram – a carpenter – to host a how-to TV series on building furniture? Morash, a self-proclaimed “wannabe carpenter who built the occasional nightstand,” says the thought of a carpenter not being able to build fine furniture never really occurred to him.

“I never thought he couldn’t do something,” Morash says. “In his very quiet way, he would figure it out.”

And Abram did figure it out. “The New Yankee Workshop” recently concluded its 17th season. Abram also is one of the two original cast members still appearing on “This Old House,” which recently celebrated its 25th season as a nationally aired show.

A Familiar Woodshop

Norm Abram’s shop does have a decent collection of hand tools. Abram “hides” his chisels in this wall-mounted tool chest, which was a project on the show. Lately, he’s become fond of Japanese hand saws. Also note his measuring and marking tools. Abram says these are the most important tools he owns.

Because of the show’s success, TV viewers already are familiar with the layout of Abram’s shop. But here are a few things you might not know: Most of the lumber is stored in an outside building. Finishing takes place in a separate room, which has a doorway leading to a room filled with gardening tools. This room used to be the utility shed for the show “The Victory Garden.” (The grounds surrounding the shop used to be the setting for the show.) The shop has an indoor staircase leading to a second floor, which is where Morash’s office is located, as well as the bathroom.

Although Morash owns the building, it’s Abram’s primary woodshop. While Abram has a small shop in the basement of his own home, he does all of his serious woodworking here. Retired machines and tools typically go to Morash’s personal woodshop, which is located on his property in Nantucket, Mass.

Many of the woodshop’s fixtures that make the shop unique, such as the miter saw stand, the router station and the work hutch, are projects Abram has built for the show. (For a virtual tour of the workshop, visit newyankee.com and click the “Tour the Shop” link.)

7 New Yankee Workshop Myths

This massive miter saw stand and storage center was a project on the show. Directly underneath the miter saw is a roll-around scrap bin.

Despite the knowns, myths still run rampant. Yes, there’s a Timesaver (a very wide wide-belt sander) in the shop that’s probably worth more than my salary. There’s also an excess of clamps and quite a few drills and routers. But much of the shop is actually quite Yankee-esque: Hand-me-down tools cover the shop’s walls and old Maxwell House coffee cans (storage bins) abound. So instead of taking the time to describe placement of tools, I thought it prudent to instead dispel some of the more common myths.

1. The New Yankee Workshop is a professionally designed set for TV production.

Everything in Norm Abram’s shop isn’t brand new. Here you can see some well-worn tools stored in an old coffee can, Yankee style.

There aren’t hidden holes in the walls for camera lenses and there aren’t missing walls. Several dusty lights hanging from the 16′-high ceiling are the only indication that a TV show is shot in the shop. Otherwise, the space feels and functions like a woodworking shop.

Shortly before the first show aired Abram and Morash worked together to transform an existing building into the workshop. They designed the shop using a floor plan and a couple elevations drawn up on an 81⁄2” x 11″ piece of paper. While sitting on an airplane, they sketched out where they wanted the tools.

The saltbox-shaped shop is 36′ x 26′ (this doesn’t include the finishing or lumber storage areas). One wall is only 8′ high, hence the saltbox shape. The high ceiling (which has several skylights) is great for swinging long boards around, and for tucking away the lighting needed for the show. The shop’s concrete floor features radiant heat.

However, the shop isn’t perfect. Abram says it was a serious mistake to not put dust collection ducts in the floor. Another problem with the floor: It’s concrete. After a long day of building, Abram says he longs for a softer wooden floor.

2. Abram only uses machines and tools the show’s underwriters give to him.

Unless you’re familiar with Delta Machinery (one of the shows several underwriters), you probably wouldn’t know that Delta tools abound. In accordance with PBS guidelines, stickers are carefully placed over manufacturer names on all the tools and machines in order to create a generic shop.

Most of the tools and machines used on the show are gifts. However, Abram says he refuses to use a tool just because a certain manufacturer gave it to him, even it if makes the manufacturer mad.

“We don’t use anything because it’s given to us,” Abram says. “We use what we use because they work. We’re going to use the tools we think are best.”

Abram is careful about discussing his favorite tools and machines because he works for a show on public television and doesn’t want to be seen as endorsing a particular brand. However, long-time viewers all know which tools have become mainstays in the New Yankee Workshop (think: red clamps) because they’re used in project after project.

3. Almost everything in The New Yankee Workshop is expensive and new.

The Timesaver aside, the tools in Abram’s shop are the same tools seen in shops across the country. Yes, he owns more than one router (actually, there’s a drawer full of them). But most woodworkers own at least two routers and most professional woodworkers own several for projects that require several setups.

Almost all of the tools are well-used and well-worn, and many of them are hand-me-downs: An old Disston hand saw hanging on the wall belonged to Morash’s father.

As far as the Timesaver is concerned, OK, it’s a bit much. But to Abram, it is what it’s called – a time saver. Although Abram tries to keep his weekends free, he typically works 121⁄2-hour days Monday through Friday. From early spring through late fall, a new episode of “The New Yankee Workshop” is shot every other week. Therefore, Abram typically has 11⁄2 weeks to build each project, from start to finish. And on top of that, he builds each project twice. The first time he works out all the kinks, alone. The second time most of the process is filmed.

4. The New Yankee Workshop is virtually void of any hand tools.

The invention of the word “Normite” is just one example of how prominent the “power-tool-only” reputation has become. Abram says that many people believe that if they own the same number of power tools Abram uses on the show, then they could build the projects he builds, too. Abram says this belief isn’t true – woodworking requires skill and much of that skill requires being able to cut a tenon with a hand saw just as easily as you would with a table saw – something Abram has proven he can do.

Several projects from the show have required hand work. Abram hand-cut dovetails when building the Federal-Style Game Table, for example. But Abram says two problems exist with incorporating hand tools into the show: Viewers of the show love power tools and there’s not enough time.

Of course, this doesn’t mean Abram isn’t fond of hand tools – in fact, he’s quite particular about them. For example, he keeps a collection of inexpensive chisels in bright yellow plastic trays propped up against a window in his shop. This isn’t because they are his favorites. Rather, these are the ones he uses for quick-and-dirty chisel jobs. When working on a project that requires fine chisel work, he’ll use his better ones, which he keeps safe in his hanging tool cabinet.

5. Abram has a crew of woodworkers building projects for the show.

Abram builds each and every project alone, start to finish. His first step when building a project is to find a piece of furniture he wants to build and record the furniture’s dimensions in a notebook. This process is always filmed. Abram also takes digital pictures of the piece, which helps him in his planning.

If the project is complex, Abram will create a couple sketches – using these sketches, his digital pictures and the recorded dimensions, he’ll then get his necessary material. “I always have very little leftover,” Abram says. “There’s so much deep Yankee blood in me – I don’t cut many extra pieces.”

Abram does have one shop assistant, Wade Burcher. Burcher’s main responsibilities are to keep the shop clean, the tools sharp and the machines well-tuned. Burcher, who has been with the show for a couple years, is himself a woodworker and has watched the show since he was a child. (He’s also a whiz with “New Yankee” facts – Morash and Abram claim he knows more about the show than they do.)

6. Abram knows everything there is to know about woodworking.

Abram is quick to admit that there are several woodworking skills he has yet to master, including carving and marquetry. These two skills in particular are ones he’d like to learn, if he had the time. Finishing also is his weakness, he says.

7. Abram never makes a mistake.

“People always ask, ‘Do you make mistakes?’” Abram says. “Yeah, I make mistakes.” Morash says that viewers are always asking for a blooper tape. However, the fact of the matter is, there isn’t one. Because Abram builds each project twice, rarely does he make a mistake while building a project during a shoot.

But, Abram is human. Hanging on the wall in the shop is a piece of wood that Abram botched while building the Butler’s Table. The show’s staff made sure it was put on prominent display. “The beasts that we are, we feasted on this,” Morash says. “It was an example of his fallibility. It was cruel, inhuman and we will pay for it in our next life.”

Morash says part of the appeal of the show is that there is a certain satisfaction in seeing Abram building something without making a mistake. “It’s beautiful workmanship going together to form something wonderful,” Morash says. “There’s a calming influence to watching someone do something well.”

A Woodshop That Lives Forever

Much of woodworking is a practice in patience, and for years viewers have appreciated Abram’s studied approach to the craft. Abram says patience is a trait he inherited from his father, a man who didn’t believe in shortcuts. Patience is what allows Abram to approach new tasks in a methodical manner, allowing him to understand a new technique or tool after experiencing it just once.

Morash laughs as he describes a typical scene in the shop whenever a new machine arrives: He and Burcher are tearing the box apart, ready to put it together, while Abram is quietly standing in the corner, reading the machine’s instruction manual.

While Abram isn’t planning on quitting the show anytime soon, he also doesn’t plan on hosting the show forever. “Everything has to have an end point,” Abram says, adding that this show’s end point will be when he stops having fun. “I’ll be 56 this year,” he says. “By 60, I want to be in charge of my own life.”

Morash recognizes that the show must have an end point, too. He says he fantasizes Abram’s shop someday being on display at The Smithsonian National Museum of American History, similar to the museum’s exhibit of Julia Child’s kitchen (Morash produced several of her shows). And while the display most likely will include all the glitter of a Timesaver, if it’s true to the show, there will also be some coffee cans, Abram’s well-worn leather toolbelt, and some sawdust on the floor, too. PW

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.