We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

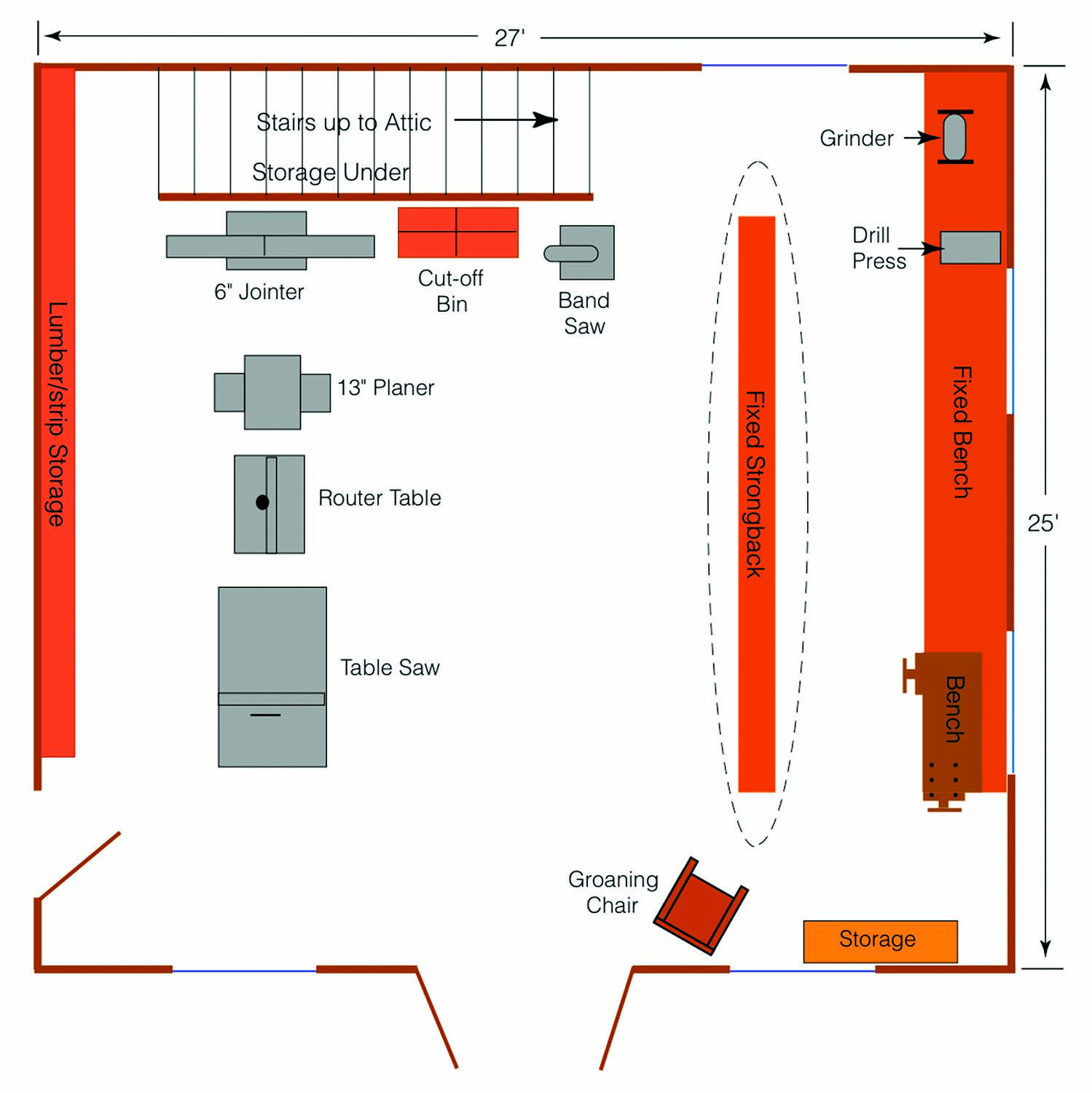

My boat shop is the result of years of frustration. I used to build cedar-strip canoes and sea-kayaks in an attached 1-1/2 car garage and was constantly fighting both the confined space and the shop dust that kept migrating into the house. So, when I retired and had a bit of extra time, I had a local builder construct the shop and then finished the interior space myself. Now I have lots of open space to work around 18′ long boats, a high ceiling and no internal support posts to avoid while maneuvering the long cedar strips that I use. Everything else in the shop reads “boat-building,” too. Along one wall I built a long workbench to fabricate decorative accent strips for the boats. I installed fluorescent lighting above the bench to complement the natural light from all the windows and doors. The white ceiling helps, too.

Under the bench, my fiberglassing tools and epoxy are close at hand. The small parts and odd surfaces that go with boat building require that I have at least one of virtually of every type of clamp you can imagine. I store most of them, as well as sanding and sharpening supplies, in restaurant plastic bus trays, a trick I learned from American Woodworker #136; it’s a simple and efficient system for storing small items.

Under the bench, my fiberglassing tools and epoxy are close at hand. The small parts and odd surfaces that go with boat building require that I have at least one of virtually of every type of clamp you can imagine. I store most of them, as well as sanding and sharpening supplies, in restaurant plastic bus trays, a trick I learned from American Woodworker #136; it’s a simple and efficient system for storing small items.

A rack on the opposite wall stores the long cedar strips and accent woods. I park my portable and stationary tools below this rack; they’re all on mobile bases, so they can easily be wheeled into action as necessary. The space above the shop is a stand-up attic for storing molds, scrap wood and stuff I don’t use everyday.

A rack on the opposite wall stores the long cedar strips and accent woods. I park my portable and stationary tools below this rack; they’re all on mobile bases, so they can easily be wheeled into action as necessary. The space above the shop is a stand-up attic for storing molds, scrap wood and stuff I don’t use everyday.

Double front doors with no outside step make it easy to move boats and materials in and out. They also allow setting up tools near the doors or rolling them outside when I have to rout end-to-end bead and cove edges on very long strips. A lean-to style covered porch for storing boats or drying lumber adjoins the shop. It’s also a great place to work outside on nice days.

Double front doors with no outside step make it easy to move boats and materials in and out. They also allow setting up tools near the doors or rolling them outside when I have to rout end-to-end bead and cove edges on very long strips. A lean-to style covered porch for storing boats or drying lumber adjoins the shop. It’s also a great place to work outside on nice days.

Clear-coat fiberglasing of the boats requires a narrow and consistent temperature range. Here in coastal Virginia we get hot, humid summers and cool winters, so the shop needs both cooling and heating. I wanted a wood stove for the winter, but combined with central air, it was too expensive. So, instead, I settled on a ductless mini-split heat pump system that’s common throughout Europe and Australia. This system has an external compressor that connects to a single internal unit, which in my shop hangs above the bench. It provides adequate heat in winter and plenty of cooling and humidity control in the summer. A ceiling fan helps circulate the air year round.

Clear-coat fiberglasing of the boats requires a narrow and consistent temperature range. Here in coastal Virginia we get hot, humid summers and cool winters, so the shop needs both cooling and heating. I wanted a wood stove for the winter, but combined with central air, it was too expensive. So, instead, I settled on a ductless mini-split heat pump system that’s common throughout Europe and Australia. This system has an external compressor that connects to a single internal unit, which in my shop hangs above the bench. It provides adequate heat in winter and plenty of cooling and humidity control in the summer. A ceiling fan helps circulate the air year round.

My shop also has a few creature comforts (after all I am retired), including a bookcase, and rocking chair and a speaker system that connects to my iPod.

My shop also has a few creature comforts (after all I am retired), including a bookcase, and rocking chair and a speaker system that connects to my iPod.

I’ve built a 17-foot sea kayak in new the shop and I’m just finishing a 17-foot canoe. I build mainly for the enjoyment, and sell the boats for a bit above cost. I’ve also become known locally for restoring wood trim on commercial fiberglass canoes. I’m thoroughly enjoying retirement, mainly because I have a great canoe shop.

Gene Burreson

Gloucester, Virginia

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.