We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

While visiting with chairmaker Bob Erickson (pictured above with his son Tor), it seems appropriate to ask, “What chair are you sitting in right now?” He explains it’s an unfinished Van Muyden chair part of a dining room set he’s building for a client in New York City. Bob’s Van Muyden Chair—three-legged, crafted of quilted maple and walnut is ensconced in the permanent collections of three museums. Sculptural yet supremely comfortable, it’s an extraordinary chair. Which is fitting, because Bob is an extraordinary chairmaker.

While visiting with chairmaker Bob Erickson (pictured above with his son Tor), it seems appropriate to ask, “What chair are you sitting in right now?” He explains it’s an unfinished Van Muyden chair part of a dining room set he’s building for a client in New York City. Bob’s Van Muyden Chair—three-legged, crafted of quilted maple and walnut is ensconced in the permanent collections of three museums. Sculptural yet supremely comfortable, it’s an extraordinary chair. Which is fitting, because Bob is an extraordinary chairmaker.

Van Muyden Chair Maple, cherry, walnut 38″ x 23″ x 23″

No sitting around

Bob’s circuitous route to woodworking isn’t an unusual one for a person of his vintage. “I started out forty years ago with a 1949 pickup truck, a circular saw, a sharpened screwdriver for a chisel and no formal woodworking training or education,” he explains.

While earning an English degree in Lincoln Nebraska, Bob took a summer class at San Francisco State, where he rubbed elbows with a woodworker. “Woodworking looked like an interesting thing, so as my college career wound down I started looking around,” Bob recalls. He familiarized himself with the work of early crafts movement woodworkers, including Sam Maloof and George Nakashima, and began hunting for a woodworking shop in which to learn the craft. After looking in Nebraska, Bob headed back to California, where he met legendary woodworker Art Carpenter, who introduced Bob to two local woodworkers who became his mentors.

Along the way, Bob lived and worked in Norway for two summers, where his wife, Liese has roots. Clearly, some of that clean Scandinavian design rubbed off. “Some woodworkers say they’re not influenced by anything or anybody,” Bob explains. “I’m influenced by everyone I meet and everything I see.” Bob eventually settled on a plot of land near Nevada City California, in the foothills of the Sierra Nevada Mountains.

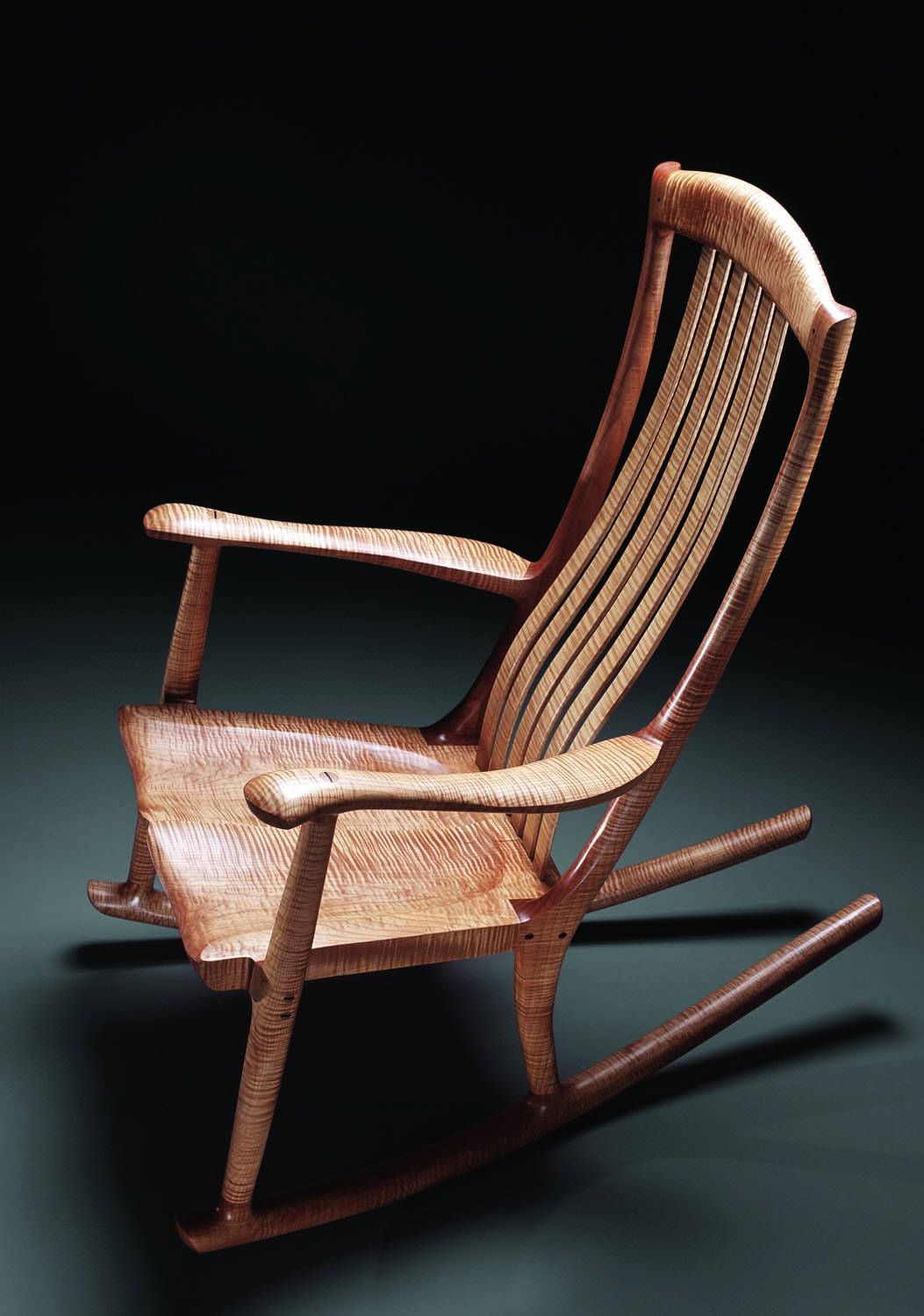

South Yuba Rocker Fiddleback maple 43″ x 26″ W x 41″

He had early success building stools. “They were fun to make and they sold,” Bob recalls. “They were also easy to haul around and ship.

It was creative work,” he continues. “Building stools required some sophistication and I wanted to make something unique and special. It also seemed to make sense to specialize rather than trying to do it all. All these things pushed me toward chair making.”

Early in his woodworking journey, Bob met Elam Sharp, an 80-year-old wagon wheel maker in Oklahoma who also made rocking chairs. “He was a character,” Bob smiles. “Even at 80 he loved the ladies.” Sharp introduced Bob to chairs with curved, flexible back slats that were mortised rather than glued into the headrest. These chairs were rustic but extremely comfortable. With Sharp’s blessings, Bob took these ideas and developed them into the contoured, flexible back chairs that have become his signature.

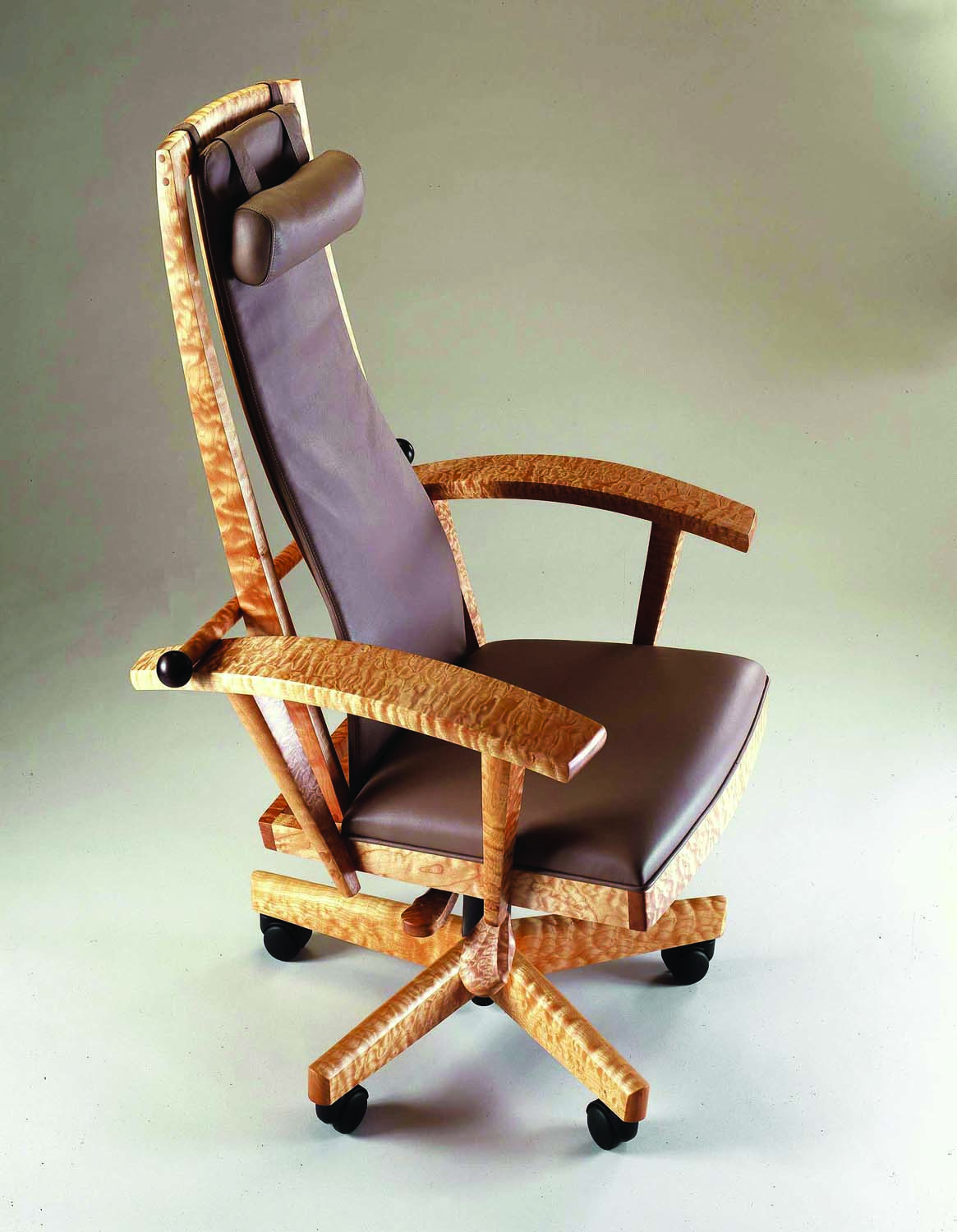

Elrod Chair Quilted maple, bubinga, leather 40″ x 24″ x 30″

Today, along with his son Tor and one other woodworker, Bob meticulously hand crafts about 75 pieces of furniture a year. Nearly 90% of their work is chairs. Tables or desks to go with the chairs compose most of their remaining output.

The ergonomics of design

Bob has invested an enormous amount of energy refining the design and ergonomics of his chairs. “Owning a chair of one’s own making is one of life’s great pleasures,” he says.

Gillian Chair Quilted big leaf maple 40″ x 25″ x 25″

The chairmaker’s goal, according to Bob, is to distribute a person’s weight over the widest area possible—thighs, buttocks, legs and back—rather than allowing it to be concentrated on a few bones, which is what typically happens when a person sits. There are a variety of ways to do this, Bob says, noting that tractor seats, Adirondack chairs and horse saddles all perform ergonomically well in their own way.

“Each person’s ‘angle of repose’ is unique—and very personal,” Bob explains. That’s why he prefers to fit each chair to its person, either in his shop or at one of the half-dozen craft exhibits he attends per year. Although most people fit comfortably in Bob’s standard-size chairs, he can make 12 different adjustments—leg height, seat depth and arm length to name a few—to create that ideal angle of repose. He pays particular attention to lumbar (lower back) support. “Sometimes 1/4″ makes all the difference,” he notes.

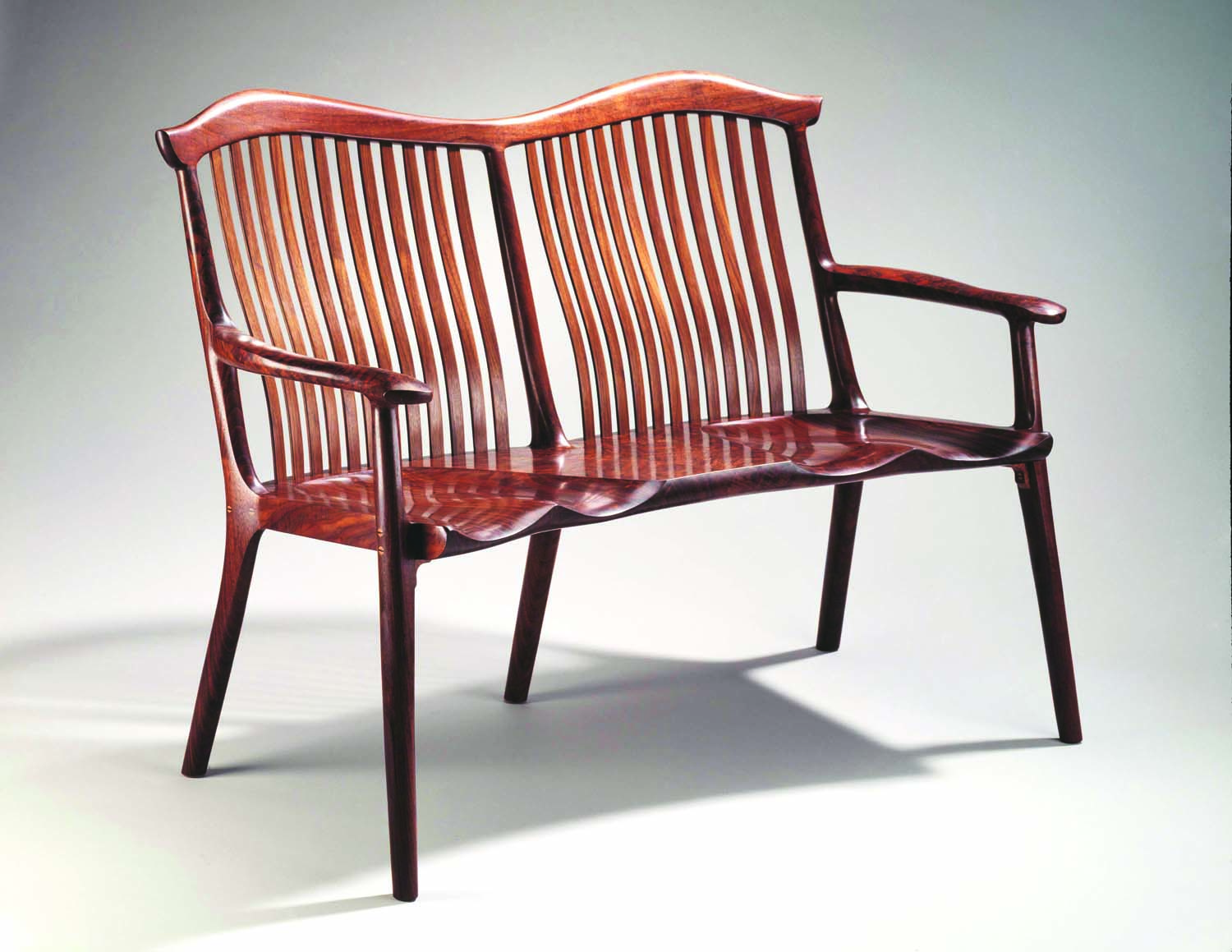

St. Paul Settee California walnut 38″ x 56″ x 28″

For simple dining, Bob recommends a fairly upright chair to provide back support, a comfortable hand position, and better orientation to the top of the table. For those who prefer two-hour dinners—during which they’ll kick back from the table, slouch a little and cross their legs—a different type of chair is better. “Part of building a chair is asking the customer the right questions,” he says.

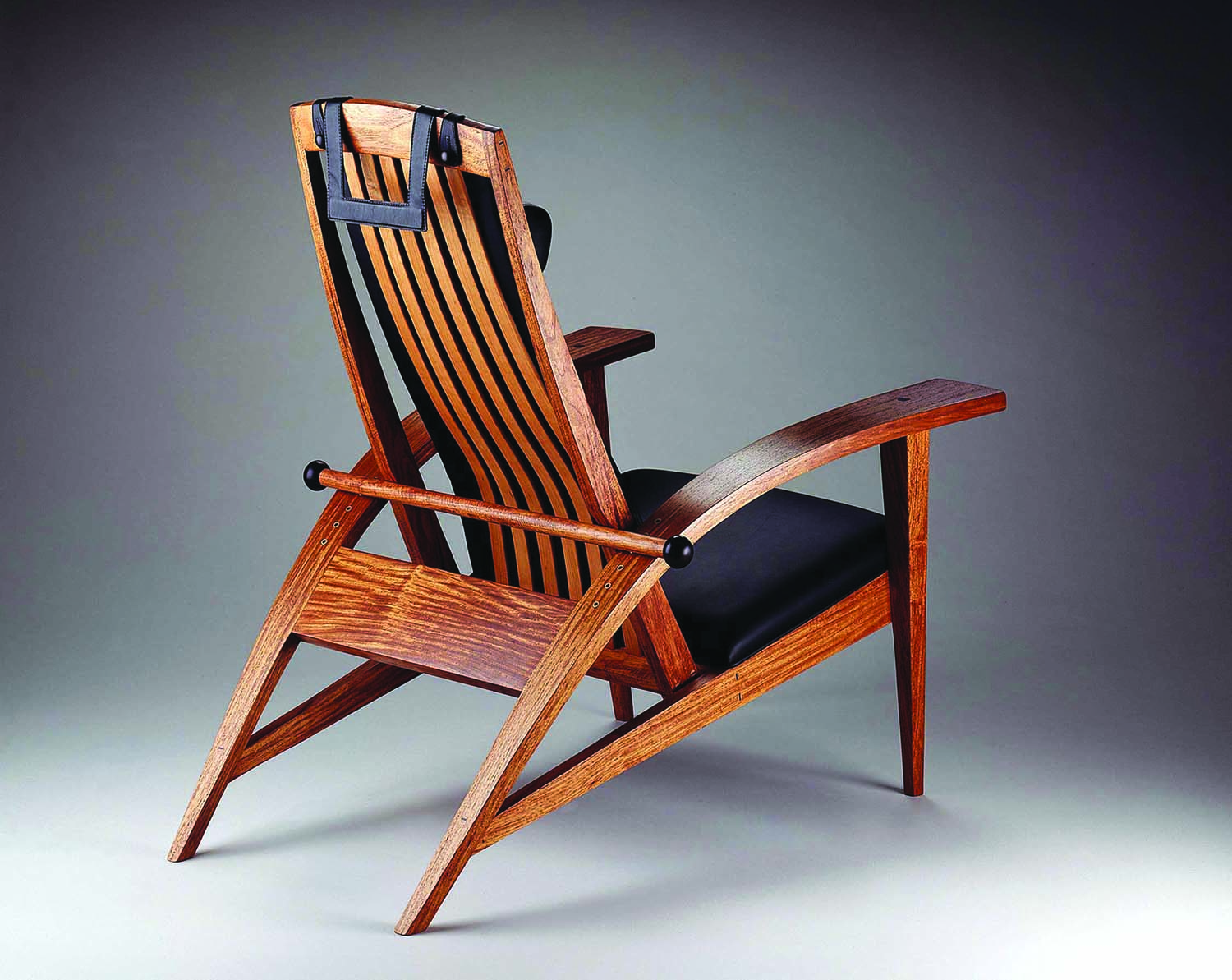

Bob encourages would-be chairmakers to think in terms of flares, curves and tapers. “The human body isn’t shaped like a box,” he says, “so chairmakers have to think ‘outside the box.’

Martinez Recliner Narra 40″ x 36″ x 46″

Start with something tangible; something real to sit on,” he recommends. “Go to a thrift store and find a chair that appeals to you. Buy it, tear it apart and then play around to personalize it: Widen the seat. Shorten the back legs. Change the arm positions or the back.”

From chain saw to mirror finish

A sinfully smooth and luxuriously comfortable contoured seat is one hallmark of an Erickson chair. Once the seat’s profile is marked on the top and front edge of a blank, Bob starts the shaping process with the least likely of tools—a chainsaw. Using a deft touch and 40 years of experience, he scores a series of tightly spaced kerfs. Then he rakes the saw back and forth to create the seat’s rough depth and contour. He switches to an angle grinder to “get rid of the lumps” and refine the shape and then finishes with a random-orbit sander.

Tashjian Chairs Front chair: Bubinga, leather Back chair: Maple, leather 40″ x 25″ x 29″

“It sounds crude,” Bob says, “but it works efficiently. In about 50 minutes I can have a seat that’s pretty close to being done.” Bob’s trademark curved back slats are bent-laminated using boards resawn into 1/8″ thick pieces and custom-made bending jigs.

Mirror-like finishes are another hallmark. Bob stresses it’s the surface preparation before the finish is applied that makes the difference. Typically, a rocking chair receives eight to 10 hours of sanding before its inspected in direct sunlight—by a different person. Then it’s sanded some more. Finally, the surface is polished using a grinder with a random-orbit head and worn-out 400 grit paper. The actual finish consists of three or four coats of tung oil thinned with a citrus-based solvent.

Westport (Adirondack) European elm 42″ x 36″ x 26″

An environmentalist, Bob dries most of his wood in a solar kiln. He loves using local hardwoods, specifically California walnut, Pacific madrone and California black oak. The power for Bob’s shop—as well for four nearby houses and another wood shop—is supplied by an array of 37 3′ x 5′ solar panels. “It’s a rare day we need to kick on the generators,” he explains.

Passing the wooden baton

Bob’s 34-year old son Tor has been involved in the business to varying degrees since he was 12 years old. But over the past two years, he has taken the reins. Though one might anticipate a degree of discord between father and son, business founder and successor, a person dropping the reins and the one picking them up, there appears to be none.

“There are some differences,” Bob says. “For instance, I’m a lot sloppier. But Tor has skills and interests that complement mine and it makes things more exciting and creative. Everything is getting better, from the finishes to the joinery. These days I come into the shop and Tor tells me what to do. I like it—I get to do the woodworking without all the other responsibilities.”

Though they’ve set their sights on upping production to 100 pieces per year, Tor stresses he and Bob will never lose sight of their primary goal—to learn from each piece in order to improve the product and the process while creating one of life’s great pleasures, one by one.

To see more of the Ericksons’ chairs and other furniture visit ericksonwoodworking.com

Spike Carlsen is the author of Woodworking FAQ and other books. His newest offering, The Backyard Homestead Book of Building Projects (Storey), will be available the spring of 2014. For more information visit www.spikecarlsen.com or follow him at www.facebook.com/spikecarlsenbooks

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.