We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Sealers. Many products are marketed and sold as sealers. The purpose, however, isn’t to seal. All finishes seal. It’s to provide easy sanding. The only finishes that are difficult to sand are lacquer and alkyd varnish, so these are the only finishes where a special sanding sealer makes sense.

An explanation of this most confusing of finishing treatments.

In the late 1980s, I hosted a local call-in radio show dealing with finishing and restoration. I remember one caller explaining that he had applied four coats of tung oil; he asked what he should use to seal the wood!

OK, so he was probably using wiping varnish falsely labeled “tung oil,” as I’ve explained many times, but four coats of any finish will seal wood quite well. Just one coat, in fact, is enough unless the finish has been excessively thinned.

Clearly, this fellow misunderstood the term “sealing.” But he’s not alone; there’s probably no term in finishing that’s more misunderstood.

A Little History

In the 19th and very early 20th centuries, there was no discussion of sealers and, so far as I can determine, there were no products marketed as sealers. The likely explanation is that almost everyone, including furniture manufacturers and painters, used shellac, which is fairly easy to sand.

But in the 1920s nitrocellulose lacquer was introduced and replaced shellac in furniture factories. Unlike shellac, lacquer is not easy to sand because it gums up sandpaper, causing small lumps called “corns.” Because the first coat should always be sanded to remove the roughness, manufacturers created an easy-to-sand finish, which they called “sanding sealer.” The name is logical enough when you remember its purpose.

Varnish has a similar problem of gumming up sandpaper, so as the market for this finish grew, sanding sealers were developed for it, also.

Sanding Sealer

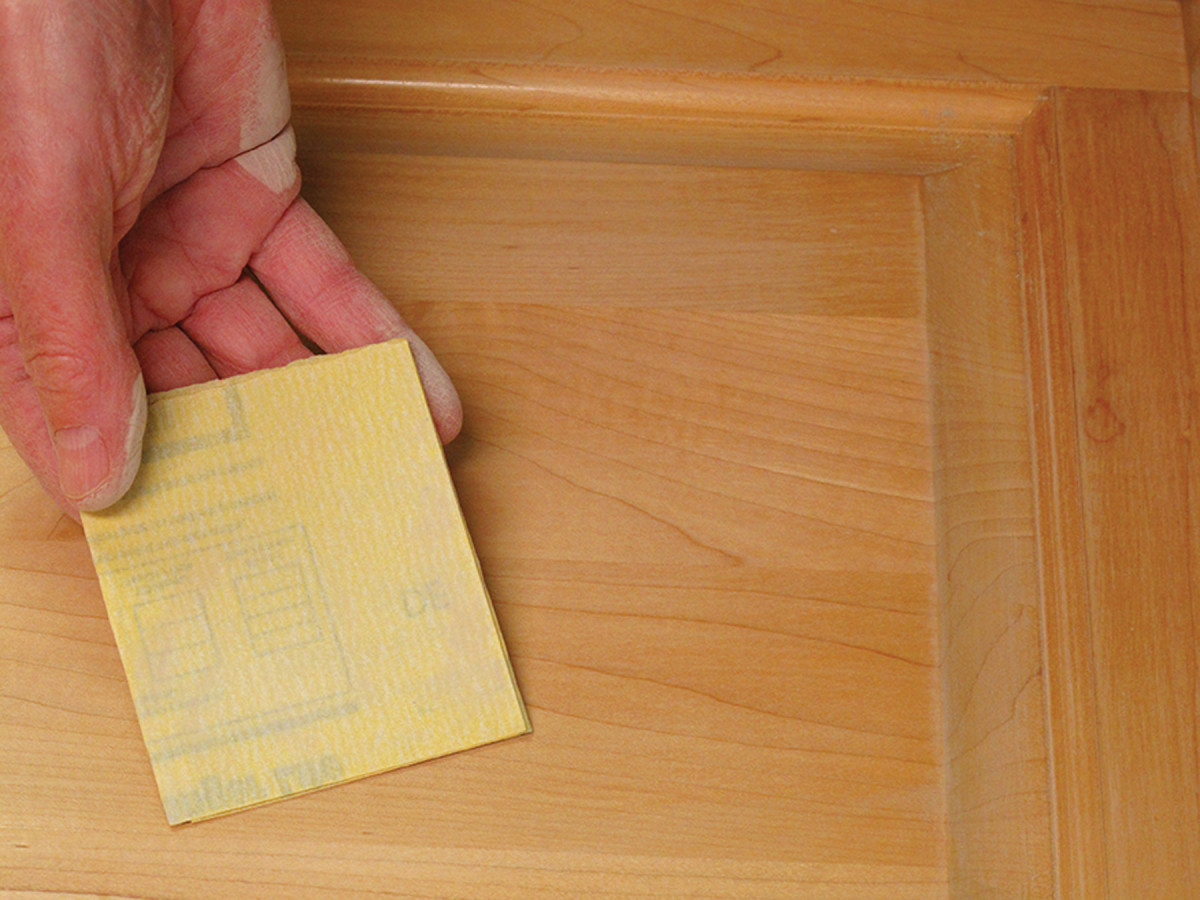

Lacquer. Nitrocellulose lacquer is difficult to sand because it gums up sandpaper causing little lumps of build-up, called “corns,” that scratch the surface. This happens even when using stearated sandpaper, as I’m doing here.

So what is it that makes sanding sealer different from the finish itself – lacquer or varnish? It’s the addition of zinc stearate to the finish. Zinc stearate is a type of soap. Think about what would happen to the dried finish film if you added the characteristics of hand soap to the finish.

The film would be slicker, so it would be less likely to clog sandpaper. This is good. But then consider the negatives.

■ The film would be less moisture and liquid resistant.

■ The film would also be softer, so it would scratch easier.

■ The film would crack easier because of reduced plasticity.

■ Any finish applied over the sanding sealer might not bond as well.

Sanding sealer. Sanding sealers for lacquer and alkyd varnish contain zinc stearates, a type of soap. The stearates make the finish easy to sand, but they weaken the finish by making it less moisture resistant, less scratch resistant, less plastic so it cracks easier, and they weaken the bond of many finishes.

These qualities are easy to picture once you know that zinc stearate is soap. Sanding sealer is therefore a trade-off between easier sanding and these four negative qualities. The conclusion is obvious: You put up with the more difficult sanding of lacquer and varnish unless your project is large, in which case the time and effort saved, together with the savings on sandpaper, are worth the trade off.

So factories and cabinet shops typically use lacquer sanding sealer, but there’s seldom a need for you to use lacquer or varnish sanding sealer unless your project is large. You can make the sanding a little easier by sanding with stearated sandpaper.

Polyurethane

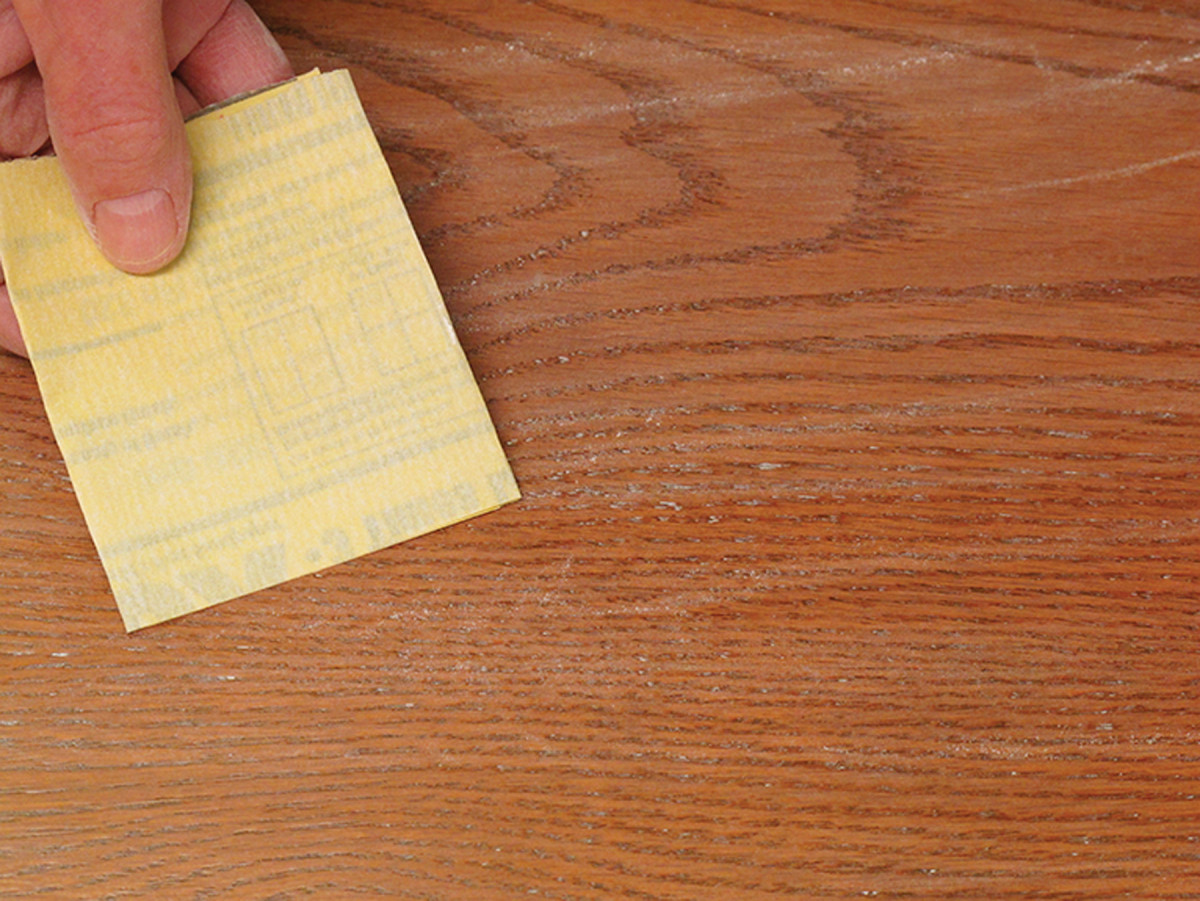

Sanding polyurethane. Polyurethane varnish dries hard and is easy to sand, so no special sealer is needed. In fact, using anything other than the polyurethane itself as the sealer weakens the total protection and durability of the polyurethane film.

If you have been finishing for a decade or longer, you’ve surely noticed that polyurethane varnish has largely replaced traditional alkyd varnish in the stores. Polyurethane cures harder than alkyd varnish and doesn’t bond as well to soapy sanding sealer. If the finish takes a hard knock, the polyurethane can separate.

As the market for polyurethane grew, manufacturers became more aware of this problem and began cautioning against applying it over a sanding sealer. But woodworkers had been conditioned to the need for a special sealer, so shellac was increasingly promoted. After a while, it became apparent that polyurethane didn’t bond well to shellac either because of the wax it contains naturally.

So Zinsser (Bull’s Eye), the only remaining supplier of liquid (as opposed to flake) shellac, created a dewaxed version called SealCoat, which they marketed as a sealer for polyurethane. It works well enough, but consider how absurd this is.

Polyurethane sands very easily, meaning it powders and doesn’t clog sandpaper. So no special sealer is needed. A first coat of shellac, in fact, can only have the effect of reducing the protection and durability of the total film. Why would you want to do this?

Water-based Finish

Sanding water-based finish. As with polyurethane, water-based finish dries hard and is easy to sand without gumming the sandpaper. So there’s no need for a special sealer under water-based finish.

Beginning in the early 1990s, water-based finishes became widely available. Water-based finishes also dry hard and sand easily. But the market was conditioned to need a separate sealer. So manufacturers provided a water-based sanding sealer. Whether this was because of their own ignorance of “sealing” or because they just wanted to sell you another product, or both, you can decide.

They did, however, come up with quite an ingenious reasoning for the sanding sealer. They claimed reduced grain raising. Water-based finish is slightly alkaline, and alkalis increase grain raising. So the sanding sealers were made, or at least claimed to be made, more acidic. This reduced the durability, but it was supposedly worth it to reduce grain raising.

I was never able to tell any difference in grain raising. I have to assume that others had the same experience (or lack of it), because manufacturers seem to have given up on this explanation altogether. Some, targeting the woodworking market, still offer a water-based sanding sealer, but you don’t often find it in paint stores or home centers. There’s just no need for it.

Thinning

Wooden boats. The wooden boat community, especially, believes it’s best to thin the first coat of finish about half to get a better bond to the wood. But there’s no evidence for this. It’s water getting under the paint or finish that causes it to peel.

Thinning a finish (varnish or lacquer) also makes it easier to sand because the thinner film hardens faster. So you sometimes see instructions to thin the first coat half with the proper thinner.

But the explanation is rarely easier sanding. Instead, it’s better bonding. The wooden-boat community, especially, buys into this explanation.

Though deeper penetration leading to better bonding may seem to make intuitive sense, I’ve never seen any evidence for this. The reason finishes peel isn’t because of lack of penetration. All finishes bond well. It’s because moisture gets underneath the finish, and the best way to keep moisture out is with a thicker build. Thinning the first coat reduces the total build unless you apply additional coats.

Summing up, it’s best not to use sanding sealer or shellac for your first (sealer) coat unless all your coats are shellac or your project is large and you’re finishing with either lacquer or alkyd varnish. And there’s no reason to thin the first coat.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.