We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

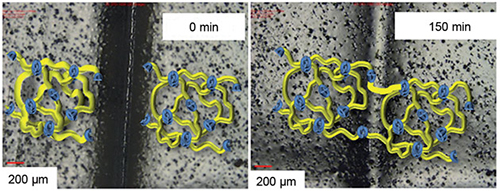

A scratch in paint fills in fairly well in 2 1/2 hours, at which point the molecules crosslink and become solid again.

Smart coatings fascinate me. In an earlier post I told you about a paint that uses nanotechnology to cause pee to bounce off walls back onto the shoes of the perp. In another post I told you about a coating that self-heals when exposed to heat or UV light. Here are a few more smart coatings I’ve come across.

Researchers at the University of Reading in the U.K. have developed a self-healing polyurethane that is unique in that it fills in damage at low temperatures, in contrast to several others that work only when heated. Low temperature healing makes this coating not only useful in paints and finishes but also for healing cuts in the human body.

Scientists in Ireland have developed a water-based coating that can be baked onto a surface to become 99.9 percent resistant to superbugs such as MRSA, E. coli and other fungi. This coating works on glass, metallic and ceramic surfaces without the aid of UV light, so it is great for indoor surfaces – for example, those in hospitals. But it can also be used on many surfaces people touch a lot, such as handrails and door handles. Scientists are working on incorporating their technology into paints and plastics for use on many other surfaces, especially cell phones where bacteria can live for up to five months.

A nanotechnology coating developed in Israel at Ben-Gurion University of the Negev impedes the growth of surface bacteria on metal and could be used as an anti-fouling agent in coatings applied to submerged ship hulls and bridge structures. It could also be used on medical implants and surgical tools to prevent infection.

And one last example (having nothing to do with woodworking but which will benefit all of us), researchers in San Diego, using slugs as their inspiration (they noticed that slugs come out of the ground at night with no dirt on their bodies), have developed a coating that exudes a silicone substance that is so slick that ice can’t adhere to it. The ice simply slides off. The silicone substance is secreted from the coating when temperatures fall below freezing, and it retreats back into the coating when temperatures rise above freezing. Obvious use: wings of airplanes to eliminate the long waits for deicing before takeoff.

Want to learn more about finishing from Bob Flexner?

Want to learn more about finishing from Bob Flexner?

Check out his book “Flexner on Finishing,” at shopwoodworking.com

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.