We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Three configurations. Spray guns are available in three configurations: siphon-feed with the cup under the gun, gravity-feed with the cup on top of the gun, and pressure-feed where the finish is fed to the gun through a hose connected to a separate pressurized pot. To illustrate the three configurations, I’m using the Apollo Atomizer spray gun, which is unique in that it can be set up in all three configurations and it can run off either a turbine or a compressor.

As I’ve explained many times in Popular Woodworking, you can achieve a near-perfect finish using a rag or brush: You can apply a wipe-on/wipe-off finish such as oil, wiping varnish or gel varnish; you can sand a brushed finish level and cover the sanding scratches with wiping varnish or gel varnish; or you can sand a brushed finish level and rub it to the sheen you want using fine abrasives.

But spray guns have some important advantages over brushing or wiping. The most obvious is application speed; applying a finish with a spray gun is much faster than brushing or wiping.

Spray guns also allow you to use fast-drying finishes to build a thickness rapidly with minimal dust nibs and make it possible to apply a finish film that is almost perfectly level (no orange peel) and to “tone” the wood.

Toning is spraying a finish with a little colorant (pigment or dye) added to tweak or adjust the color of the wood – whether stained or not. Toning can also be used to create highlights and other decorative effects.

Toning is spraying a finish with a little colorant (pigment or dye) added to tweak or adjust the color of the wood – whether stained or not. Toning can also be used to create highlights and other decorative effects.

The downsides of spray guns compared to brushes and rags are greater cost, increased waste because of overspray, and considerably more complexity to keep the tool in good operating condition.

The downsides of spray guns compared to brushes and rags are greater cost, increased waste because of overspray, and considerably more complexity to keep the tool in good operating condition.

So how do you choose a spray gun if you decide you want to take advantage of its benefits?

It’s actually quite straightforward. First, you decide on your source of air: compressor or turbine. Second, you choose a spray-gun configuration: siphon-feed, gravity-feed or pressure-feed. Third, you decide on quality – that is, how much you’re willing to pay.

And finally you choose a brand. Because competition keeps all manufacturers on the cutting edge of the technology, this is not as complicated as you may think.

Source of Air

Compressors. Compressors big enough to supply spray guns sometimes come with wheels but are otherwise not easily portable. Turbines are small and fairly light so they are very portable. This compressor is 5 hp, produces 15 CFM and has a 60-gallon tank. The turbine is three stage – the smallest that atomizes adequately.

Your first choice is between a gun that runs off a compressor and one that runs off a turbine.

It’s important to emphasize that almost all compressor-supplied spray guns sold today produce the same soft spray, called HVLP, or High-Volume Low-Pressure, as do turbine-supplied guns. Practically speaking, there is only HVLP anymore.

Choose a compressed-air spray gun if you already have a compressor that produces at least 7 or 8 CFM (about 2 horsepower) and has a 20-gallon or larger air-storage tank, or if you need a compressor to operate other tools such as a sander or nail gun.

Choose a turbine spray gun if you need portability or if you’re short on space; turbines are small. Turbine spray guns are usually sold together with the turbine, but you can mix and match if you like because the connections are standard.

A compressor gives you more control over the air to the gun than a turbine does because you can increase the pressure as much as you want (though going over 10 pounds per square inch at the air cap breaks the definition of HVLP and can be illegal in some areas). But the air produced by a turbine is dry so there’s no need to insert moisture-removing filters as there is with compressors.

Configuration

Spray guns that operate off each air source are available in three configurations: siphon-feed, gravity-feed and pressure-feed. All three work well, but for slightly different situations.

The siphon-feed configuration has a material cup attached under the spray gun. In the old high-pressure guns, a vacuum draws the fluid up through a tube into the air stream where it is atomized.

Atomization. The biggest difference between inexpensive and expensive spray guns is the quality of atomization they produce. The finer the atomization of the liquid material, the more level the surface produced—that is, the more reduced the orange peel. The spray pattern on the left (made by an inexpensive spray gun) has a much poorer atomization than the spray pattern on the right, which was made by an expensive spray gun. This is evident from the much larger dots around the edges of the pattern on the left.

But high-volume air in HVLP guns doesn’t create enough suction to do this. So the cup has to be pressurized through a tube running from the gun body to the cup. Some of the air is thus siphoned off from the airflow, which can cause poorer atomization and increased orange peel if the air supply isn’t adequate.

Though most under-the-gun cups are now pressurized, manufacturers still call them siphon-feed.

Gravity-feed guns, with the cup on top of the gun, don’t need to be pressurized. The fluid flows into the atomizing air stream by gravity alone. No pressure is needed, though some turbine-supplied guns do pressurize this cup to increase the fluid flow.

Having the cup on top of the gun has the advantage of eliminating the possibility of dragging the cup across a horizontal surface if you aren’t careful.

But you can fit a siphon-feed spray gun into an interior cabinet space much more easily than you can a gravity-feed gun, and a siphon-feed gun is more versatile because it can be converted to pressure-feed simply by replacing the cup with a connecting hose to a separate pressurized pot.

The pressure-feed system, with its separate pot that is pressurized by compressed air, is usually limited to production situations where a high volume of work is being finished. But not having a cup attached below or above the gun frees the gun to get into small spaces and even to be used upside down. You may find that having these options is worth the extra effort involved in cleaning the pot and connecting hose.

Most turbine guns are siphon-feed. Gravity-feed guns seem to be more popular with finishers using compressors, probably because this is the configuration used by auto-body finishers. This is the bigger market, so most available compressor guns are gravity feed.

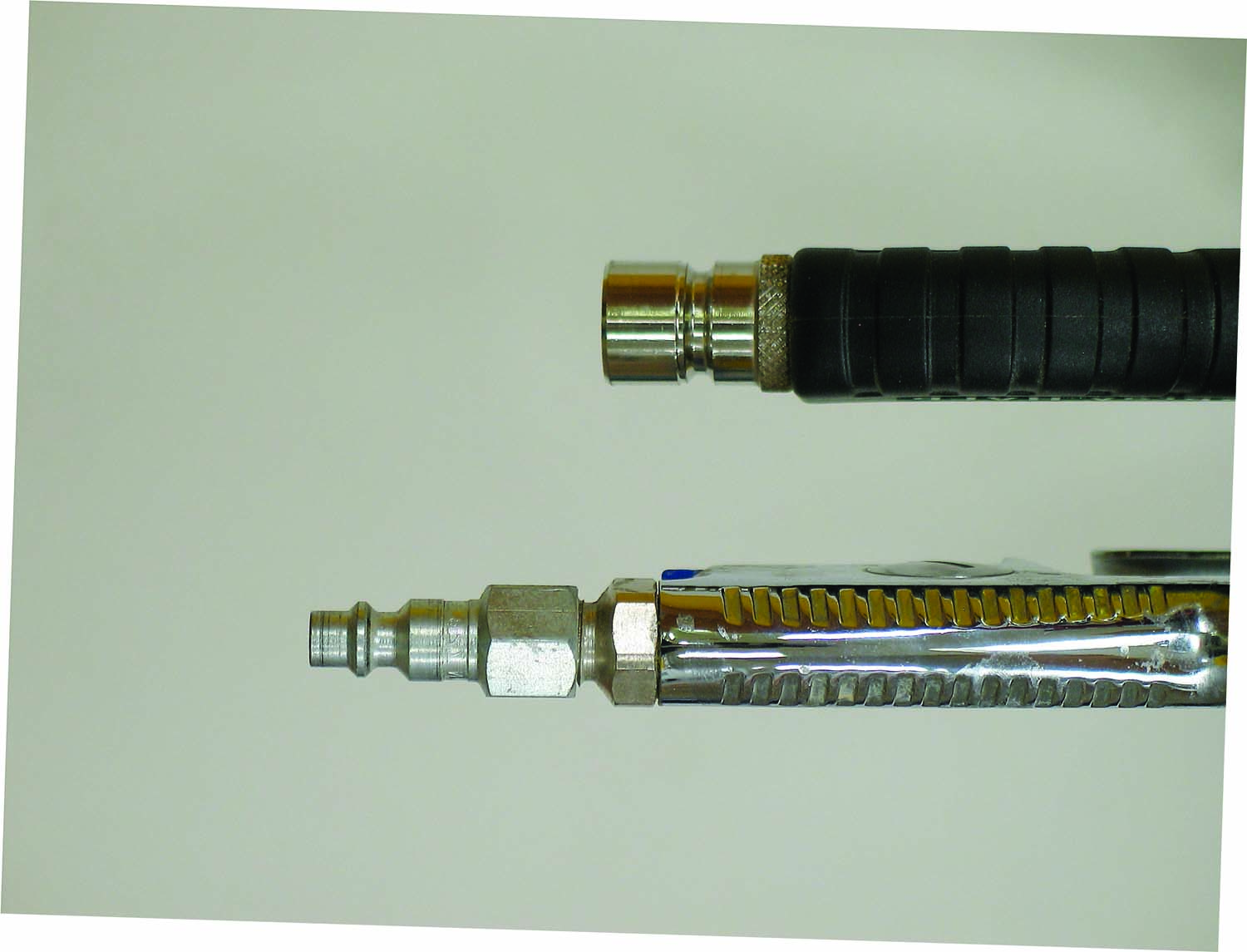

Air inlets. Quick-connect air inlets differ for compressor- and turbine-supplied spray guns. The air inlet on top is for turbine air; the one on the bottom is for compressed air.

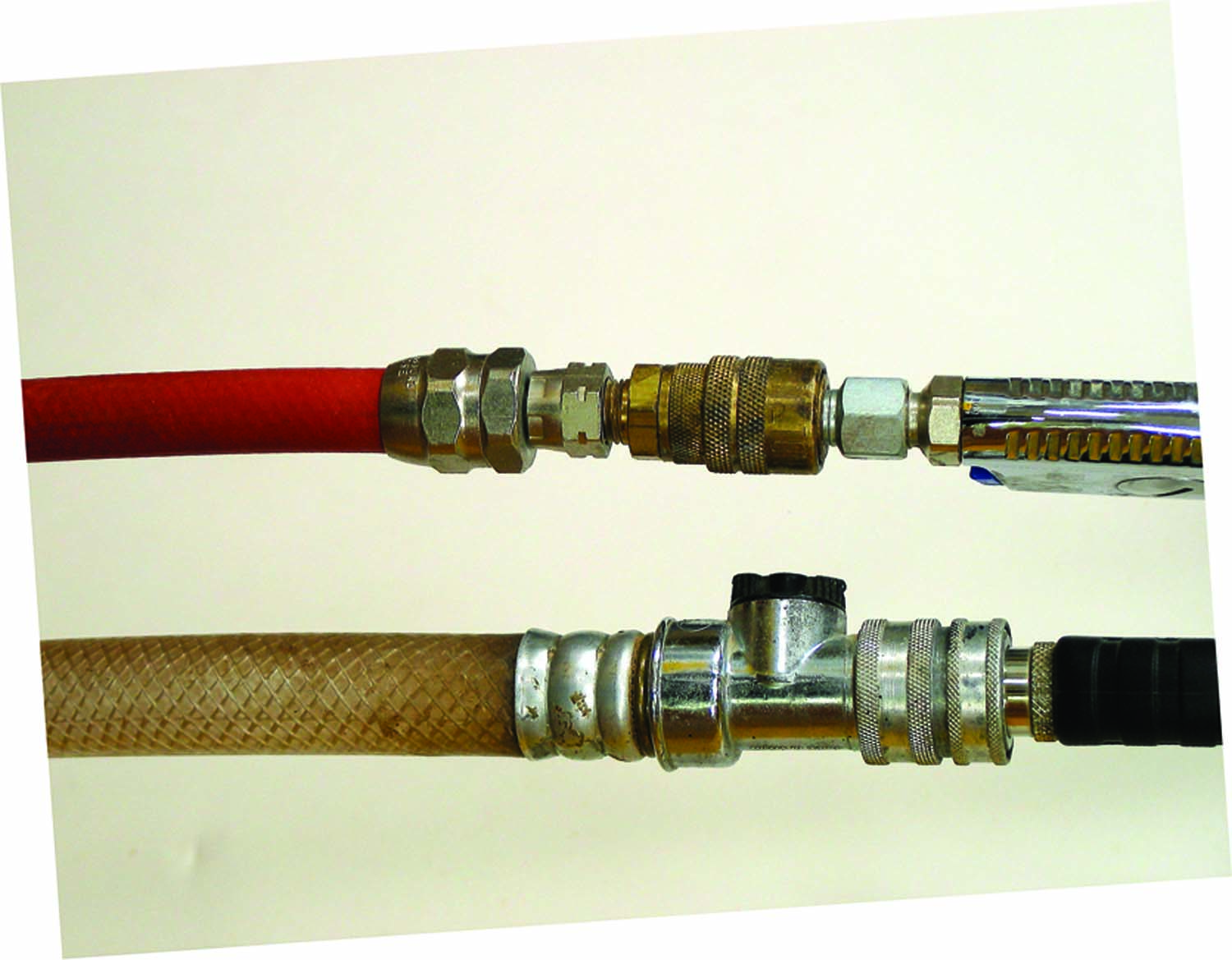

Hoses. Air hoses also differ for compressor- and turbine-supplied guns. The red air hose is for compressed air. The amber one with a larger diameter accommodates the high volume air produced by a turbine.

Quality

Just as with woodworking tools, always buy the best quality you can afford. Quality in spray guns translates primarily to better atomization leading to reduced orange peel. It also means tighter control of the spray pattern, more accurately machined parts and the use of more damage-resistant metals.

Brands

Once you’ve decided on quality, you need to choose a brand.

There’s not a big difference among brands in any given price range. So the key factor you’re looking for, after you’ve decided how much you want to spend, is service. You will usually get faster service from a local distributor than from mail order.

For compressed-air spray guns, I recommend you shop at a local auto-body supply store. In my experience, non-chain stores are more knowledgeable about spray guns than the national auto-parts chains.

Find out from the clerks which brands the local auto-body guys use and choose from among those brands. The clerks will understand the subtleties of these brands and the store will most likely stock parts.

These stores also carry very inexpensive “knock-off” spray guns, or you could buy one at a home center or Harbor Freight. These guns produce fairly good results, but the orange peel they produce is more evident because the atomization isn’t as good.

For turbine-supplied spray guns, you should also look for a distributor in your area. Paint stores that target professional painters sometimes carry turbines and guns.

Otherwise, check web sites of the brands you are considering and choose among those that provide the most helpful information and easy parts ordering. Many suppliers to woodworkers carry one or more of these brands.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.