We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Rust, the mortal enemy of steel and iron can be removed a few different ways. You can remove rust by eroding it with abrasives and steel brushes, you can use chemicals or acids, you can submerge rusted objects in a bath of baking soda and water and reverse the corrosion through a process called electrolysis. And if this is not enough, I have recently learned about a cutting edge technology that uses a laser to incinerate rust away.

Sandblasting will remove rust quickly. It will also erode other surfaces if you don’t mask them off. I sandblasted these piano stool legs to remove the rust from the iron talons feet, but also to strip the finish off the old wooden leg. I did not mask off the glass balls so they turned etched-gray.

How do I choose to remove rust? It depends on the object, the amount of rust and the time that I have.

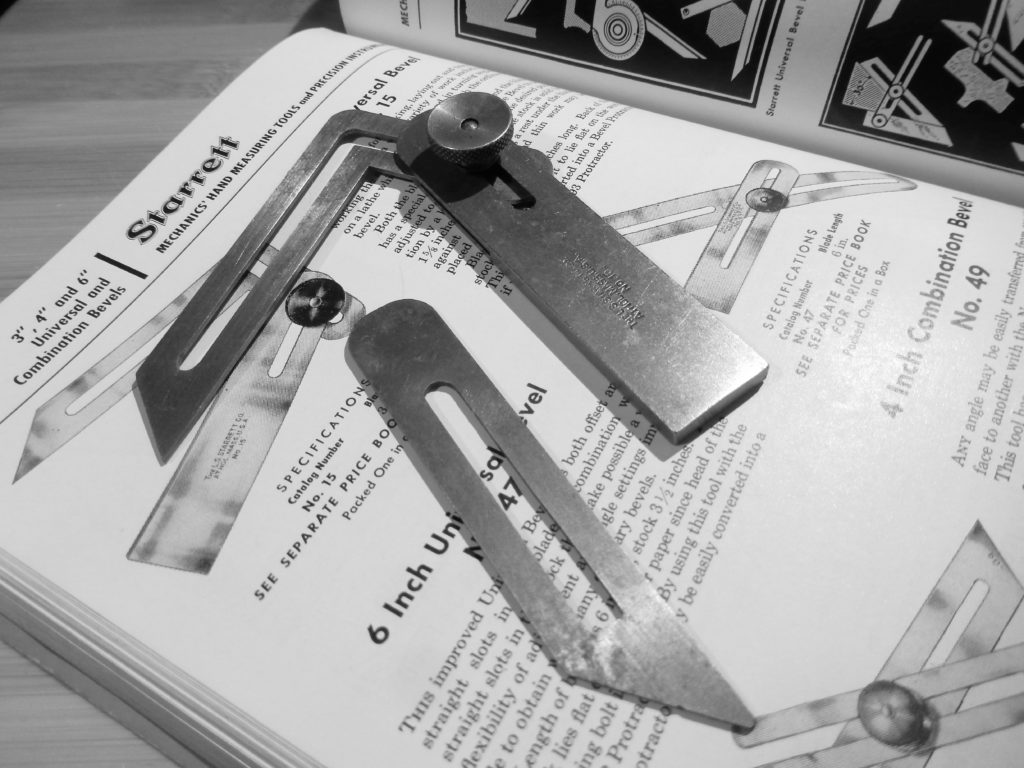

To remove rust from garden tools, sheet metal, steel furniture, wrought iron and simple hardware pieces – I would use sandpaper, abrasive pads or sand blasting. Whenever I’m dealing with intricate shapes, delicate ornamentations, objects that have threads (such as nuts and bolts), precision measuring tools, and cutting tools I choose the chemical way. The former is an aggressive and rapid removal technique that not only eliminates the rust, but if we are not careful, can erode the steel and iron surfaces near and around it. Abrasive media tends to round over corners and edges. This is the reason why I prefer not to incorporate abrasives when I’m dealing with tools such as drill bits, rusted squares, sliding bevels, rulers or any other object when factory generated precision may be compromised and will be hard to rehabilitate in a woodworker’s shop setting. In contrast to the abrasive approach, removing rust via a chemical reaction is a slower process that will affect only the rusted areas and leave the remaining surface mostly unharmed. This way, we reduce the risk of inadvertent removal of unaffected areas of steel which consequently will hurt the tool’s accuracy.

Removing rust with chemicals

As far as I know, we have two main options: acids and dedicated pH neutral chemicals. Over the years I’ve experimented with 5% vinegar 20% vinegar, citric acid solution and a material called Evapo Rust. Among the four, Evapo Rust, and other commercial products of its kind such as Rust-Oleum Rust Dissolver are the only one with a neutral pH level. That means that it is only working on the rust, and that you don’t have to worry about neutralizing the acid residues possibly left on the surfaces after the rust removal processes ended. You just need to wash with water and dry the objects. If you choose to use acids, many recommend neutralizing the treated surface (after scrubbing the rust off and washing it) via a secondary immersion of the object in a solution of baking soda.

Before subjecting an object to acids or chemicals make an effort to wash and scrub away any traces of oil and loose rust. Use dish soap solution and a stiff brush to do so.

Vinegar

5% vinegar is probably the cheapest and the most available means for removing rust. You fill a container made of plastic or glass with vinegar, then submerge the object and let the vinegar do its job. Check the de-rusting progress and scrape the rust off with a brass brush, a “retired” credit card, a piece of wood, etc. – materials which could remove the loose rust but are less likely to scratch steel and iron. In some cases, I use steel wool too, as it is equal in hardness to the scraped surface. By mechanically removing the loose rust you will allow the chemical reaction to access the remaining surface rust.

Immersing the parts in Vinegar. I used a concentrated 20% vinegar bought on amazon.com.

When you see that most of the rust has been affected by the vinegar, buff of the black patina that formed on the metal during the process using a cloth or a very fine polishing media (very fine steel wool can work too). Then rinse the object in water.

After a few minutes, I took out the parts from the vinegar and cleaned the metal surfaces with (0000) steel wool, avoiding as much as possible rounding over the edges of the bevel. It seams like the owner fabricated a makeshift straight blade that can be inserted into the bevel. Starrett does not supply it with this bevel.

Now immerse the parts in a baking soda solution, rinse in water again and dry it. You can use paper towels followed by an air blower and when that is done, you can put a light coat of oil on the object (if you intend to keep the raw steel or Iron look). Alternatively, apply a protective coat such as “Gun Blue” or wax to prevent rust from reoccurring.

Then I placed the parts in a baking soda and water solution. One teaspoon per cup of water is fine.

After rinsing again with water and drying the tool, I cleaned the threaded hole with a coiled up paper towel. Then I cleaned and dried the blade housing with a folded cardboard. We need to be creative and create solutions to the challenges that we face.

I poured a drop of oil on the threaded stud and another on the surfaces of the bevel and spread the lubricant to protect from future rust. Then I reassemble the bevel. It works and looks quite fantastic.

Using 20% vinegar would give you the same results but faster, and if you want to play with making your own acid, try the citric acid route.

Citric acid in the form of powder can be bought online and in some stores. I dilute one unit of citric acid in 10 units of water and this would get me to an approximate PH that is higher than 20% vinegar, around PH 2 or 1.5. And if we mixed citric acid in less water we could create an even more potent acidic solution. By the way, it is possible to buy vinegar at 30% concentration on Amazon and other websites stores.

There are situations where I can’t or don’t want to immerse the object in acid or rust removal solution. For instance, if I physically cannot find a container big enough, or if the rust is only in a few spots and there is no reason to subject the entire object to acid. In these cases I use a gel-like rust removed such as Naval Jelly which allows me to confine the rust remover to the contaminated areas. The application is much the same. You smear the jelly on the rust and wait until it does its magic. To further learn about your chemical rust removal options I recommend reading Chris Schwarz blog on removing Rust, Zinc and Black Oxide with a toilet cleaner called ’The Works’.

Next week I will talk about strategies to to have more control while removing rust with abrasives.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.