We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Shellac is available in several colors and in liquid or flake form.

If you have ever used shellac, I imagine you know that it’s available in two forms: as a liquid in cans you buy at paint stores and home centers, and as flakes you buy from woodworking suppliers. Though it’s more work, the advantage of dissolving flakes (in denatured alcohol) is to ensure the shellac you use is fresh. The fresher the dissolved shellac the quicker it hardens and the more water-resistant the dried finish.

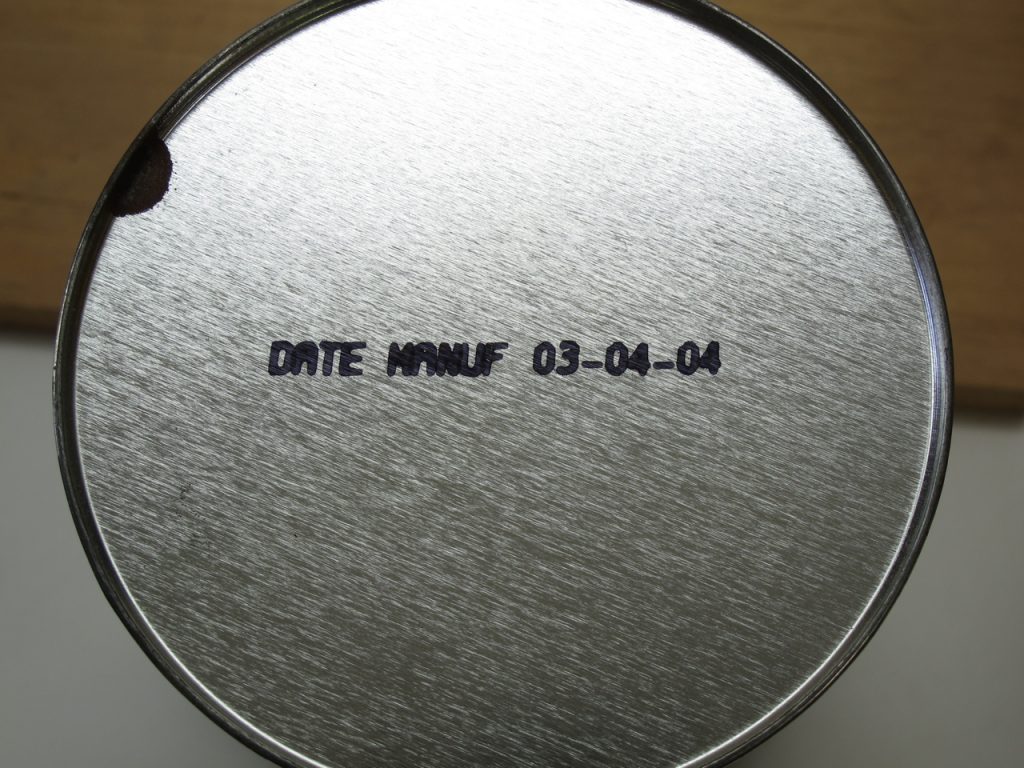

Unfortunately, the sole remaining supplier of already-dissolved shellac no longer supplies a date of manufacture (they used to, stamped right on the can), so you have no idea how old the shellac is – that is, how long the can has sat on a shelf or been stored somewhere. When finishing important surfaces, it’s best to dissolve your own flakes.

Dissolved shellac used to be dated. It no longer is.

When you do this, be sure to stir, not just shake, fairly often until the shellac is dissolved, at least once an hour. Otherwise the flakes will soften, settle, and stick together at the bottom of the container. They will form a lump that will be difficult to break up.

Be sure to stir every hour or so until dissolved.

Though this tip may sound silly and obvious, I know from my own experience that it’s not. The first time I dissolved shellac flakes, I simply combined them with the alcohol and left the jar overnight. Next day I had a fairly hard lump at the bottom, and I thought there was something wrong with the flakes. It took me a while to realize what I should have done.

To make the dissolving go faster, you can reduce the flakes to powder (for example, in a blender) or place the container in hot water. With both methods you still need to stir, however, until the shellac has dissolved.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Bob, There is still a date of manufacture…you just have to know the code..

Zinsser

The first number after the letter is the last digit in the year it was manufactured.

The second number corresponds to the month.

The third and fourth numbers relate to the actual day of the month.

There are magnetic stir plates without the heating element for just under $50. The heating element might be better in a colder environment.

Your guidance on constant stirring reminded me of a piece of equipment from my high school chemistry class. It is a magnetic stirrer. It is a plate that moves a magnetic field and causes a magnetic item in the liquid to constantly rotate, stirring the liquid. The speed of rotation is adjustable so you can fine tune how well the shellac is stirred. This is available on Amazon for a reasonable price.

That’s exactly what we use. Been using magnetic stir plates for shellac for years. You have to be careful of course but we even use a heated magnetic stir plate very low and it makes a noticeable difference.

For conservation work we need stir plates for other things anyway. Very beneficial tool.

We get fully dissolved shellac ready to use in 4-5 hours depending on the cut/ratio we are mixing.