We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

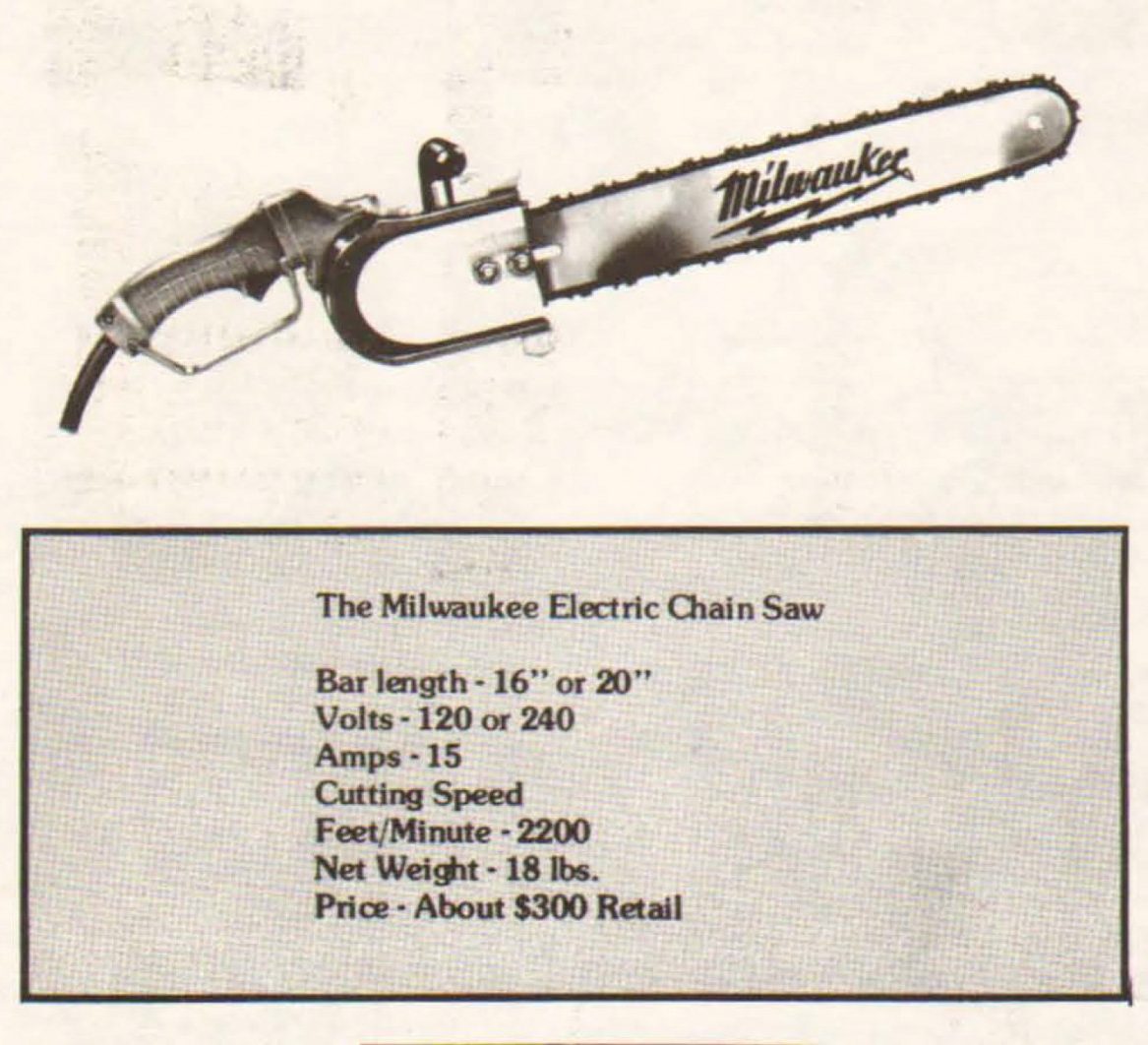

Problem Solver: The Milwaukee Electric Chain Saw

Editor’s note: This article originally appeared in the May 1981 issue of Pacific Woodworker. This particular model is obviously no longer sold in stores, but you may be able to find one on eBay if you feel like recreating the experience.

If you have ever thought about the use of a chain saw in your shop, but haven’t liked the dangers of gasoline models, an electric chain saw could solve your problems.

Many woodworkers who work on large architectural pieces, art compositions, or free-form furniture have found that using a chain saw can save them much tedious cutting work. The advantages of an electric chain saw are instant starting in any temperature, reduced maintenance, no time wasted in the mixing and filling of fuel, no exhaust fumes, and none of the dangers inherent when flammable materials are present. The only major drawback is that you are tied into a power source by an electrical cord, but this is a small price to pay for all the advantages.

One of the finest electric chain saws on the market is the Milwaukee Chain Saw. It shares all the advantages mentioned above, together with excellent Milwaukee quality construction. – -The motor is rated at 15 amps and has ample power for sawing through hardwoods. The Milwaukee Chain Saw is one of the only electric chain saws that offers the choice of a 16″ or 20″ bar length. Flush cuts can easily be made as there is no housing or bolt overhang. The saw feels very good to hold, as the handles are located with well thought-out placement. While running, the tool feels very positive with a quiet and smooth transmission of power.

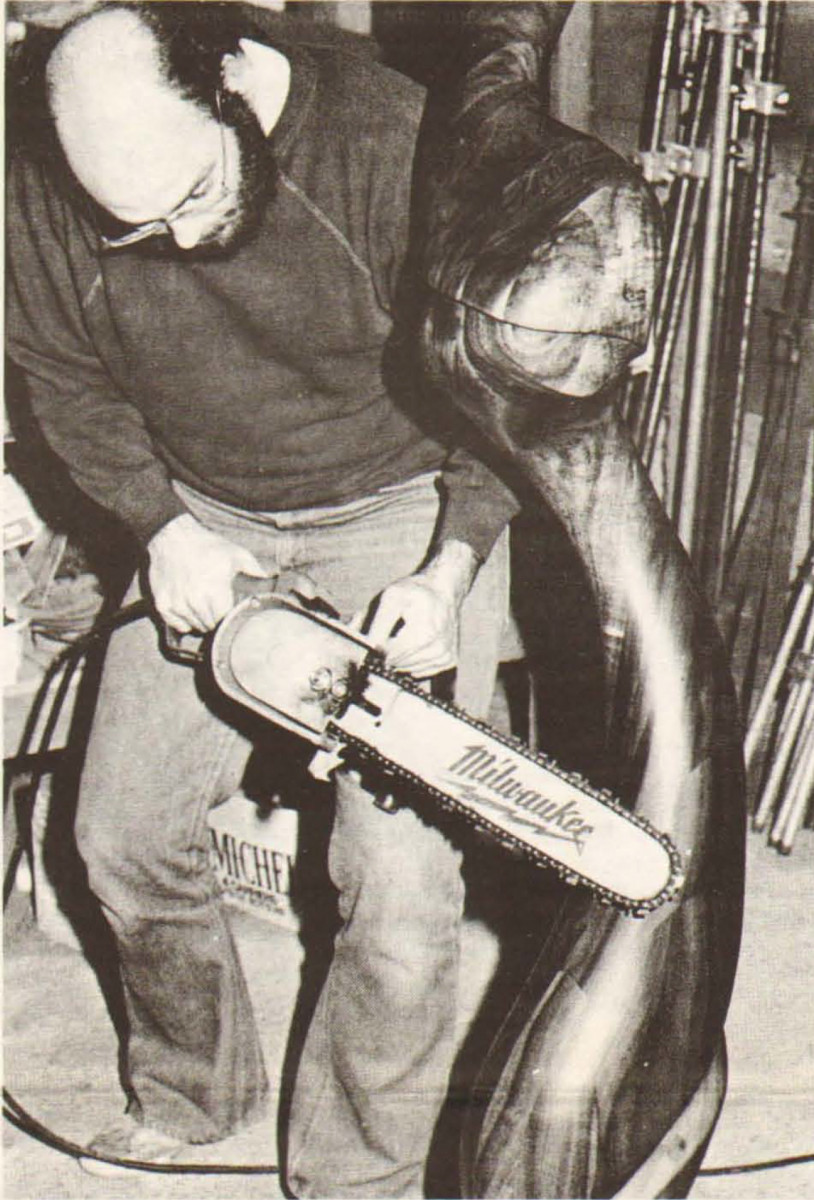

Charlie Cobb demonstrates on an almost completed banister how he used the Milwaukee chain saw to get the desired angular effect.

Charlie Cobb, a woodworker in Santa Rosa, uses a Milwaukee Chain Saw in the furniture and architectural designs that he produces for clients. Most of the work that Charlie does is custom fabrication using koa and he has been using the chain saw for about nine months. The chain saw is used to rough out the basic design and then numerous sanding steps are done to complete each project. The hassel of having to use different saws with different blades is done away with, which frees time to concentrate on the actual work.

He has done three major pieces, including the bannister he is currently working on, without the need to sharpen the chain. The glued lamination that Charlie uses in his work dulls the chain faster but there aren’t the normal chain saw hazards of cutting into dirt, rocks, or hardware in the trees.

Every shop does not have the need for an electric chain saw, but there are some specialized woodworking tasks that would be greatly simplified by the use of one. If you don’t want the negative side-effects of a gasoline powered chain saw, yet you desire this type of cutting ability, the Milwaukee Electric Chain Saw would be a good tool to investigate.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.