We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

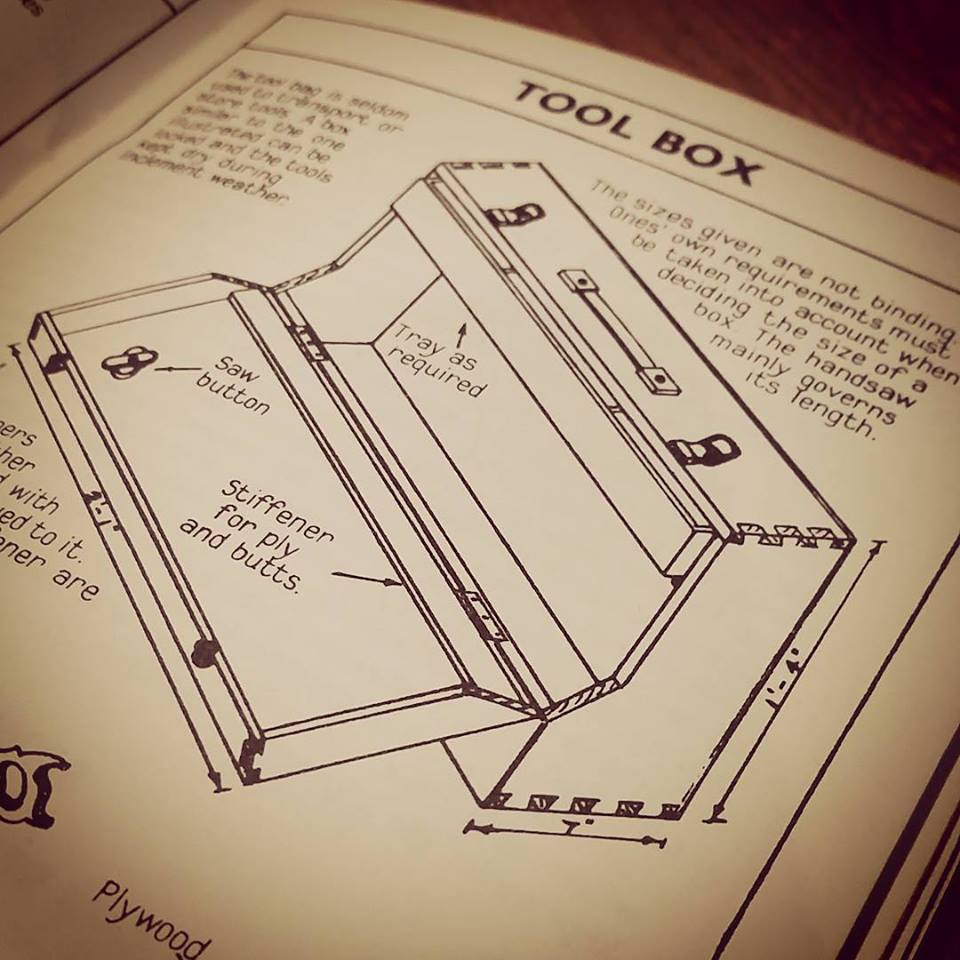

After posting this image of a tool box on Facebook, I soon had many comments such as, “Made one of these 30-odd years ago at college during my apprenticeship,” and “Made one of those in 1975 before I went to uni.” Freddy Roman had also picked one up. It’s not a common design within the books I have. I’m not sure exactly why that is, but I’d speculate that perhaps it’s so humble as to be overlooked in favour of chests, stand-alone units and wall-hanging cabinets. In addition, it typically uses plywood (a relatively modern industrial product) fixed over a wooden frame to keep things strong and light. A fellow apprentice made one when I was at college, too. I never got around to making one; I used an open plywood tote for many a year before “upgrading” to my current Stanley tool box.

I did find an example in H.F. Marfleet’s “Pictorial Guide To Woodworking Tools.” Please don’t feel you need to hurry to get a copy, but if you find one cheap, it’s good fun. It’s a book that is never afraid to tell you are WRONG in capital letters. It’s almost as if it’s written by a long-suffering woodshop teacher who had seen enough untidy benches and poorly maintained tools to last a lifetime!

I’m going to be making the tool box from Beech – mainly because there are a few boards of it hanging around our shop; also, it’s a nice, easy timber to work. That also raises another point: Many people mentioned (on Facebook) how within North America, beech is deemed unstable – but the European stuff we use seems pretty reliable. If you have any thoughts on that, I’d be interested to know. (perhaps it’s how the boards are milled and kilned, or perhaps it’s a variation of species?)

What this tool box is not is a “perfect solution” – but let’s face it: there never a perfect solutions to anything in life. However, it does offer a degree of portability for some essential tools, or a neat way to store a more pared back hand tool kit, for when more of the work is done with power tools. The construction methods are simple too – and they can be really simple if you stick with the tried-and-tested plywood, but if you want to make it as a bit more of a skill builder, use solid wood and add in a bit more joinery.

I hope to have a video up next time; more than likely it’ll be over two or three installments. I’m not going to do a heavily detailed build and I warn you there will be heavy use of FFWD where I deem it appropriate – but I will endeavour to share some sizes and reasons for choices within the video, too. I’m also trying to source a better mic so I can try to improve the video experience a touch in the short term before I can get a halfway decent camera. Anyway, if you’ve used or made a tool box like this feel free to leave a comment below.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I’ve been using one similar to this since 1974.Also similar to the one Saint Roy featured on an episode of his show-the episode is available from Popular Woodworking videos-season 21 episode 3. There was a good how-to in Fine Homebuilding magazine Dec1996/Jan1997 issue,written by Scott Wynn. On mine the tray pivots out to about thirty degrees(just enough to allow full access) rather than slides out like a drawer,which I find more convenient-it stays attached to the box,lessening the chance of it getting upset,lost,or “borrowed”. Some people say this type of box is inconvenient to work out of when working at a bench. I made my bench a little wider,then set the box on the bench at the back-works good for me-I still have two feet of bench space. It’s more convenient than a cabinet mounted to the wall over the bench imho. I’ve been thinking about building another with multiple drawers to store some of the tools I’ve acquired since getting more into handtoolwork,so I’m looking forward to your build-up.

Roy Underhill had a plan / show on one of these a few years ago. He called it a 1940’s carpenter’s box. He used to have a plan online, but it seems to have gone 404. Ted’s Woodworking might have a copy 🙂

If you look at the first illustration you should have all the dimensions you need. Basically it needs to be long enough to fix your panel saw to the back of the lid and thin enough you can carry it under your arm on the bus. All other sizes are optional. I would suggest either ½” or ⅝” pine for the caracas and ½” ply for the front and back. It needs to be right but strong as this a a box for taking on site. Some people put a handle on the top to carry it.

Thats a standard British joiners toolbox popular in the 1940s and 1950s. You see loads of then at yard sales.

I actually have two of these. Both having been made by my dad, a carpenter. One is a more crude one and the other much more refined with three trays instead of one and it also has those brass outside corner protectors at each outside corner. He has since passed and I treasure that toolbox. And still use it. I am currently looking for a replacement handle though since it was made of leather and the leather has disintegrated long ago. Its been tough to find a suitable handle. The box stores two Disston hand saws (one rip and one cross cut) nicely as well as various essential tools like hand chisels, door hinge jig, brace and bits.

As a retired builder in the UK I can say that this design of toolbox is far from unusual here. I have seen many similar ones during my career.

Regarding the comment that the rarity may be due to the best material being plywood for lightness, well ply has been around a good many years; far longer than I have. (Wiki mentions a patent going back into the 18th century but larger scale manufacture seem to have got going in France in the mid 1800’s)

I think the popularity of this design lies in its simplicity and ability to be adapted to suit the owner’s needs. It’s also closed and capable of being locked; regrettably a necessity these days.

JohnN

made one of these back in 1973 or so ; made of pine and 1/4 ply with box joints two’ full size drawers& saws hang on door, misplaced when moving house

My dad and his brother Lloyd both had one I think their father made them for them. I’m 69 so you can see they’ve been around for a long time.

I have one similar to this that I bought used close to 30 years ago. It’s larger: 31 1/4 x 13 1/4 x 6 1/2. No dovetails, just rabbeted corners on 5/8″ pine frame and 1/4″ fir plywood panel sides. Heavy brass corners (8) let in. Single latch and a steel handle; piano hinge on the door. Four separate drawers/trays on the inside (2 rows of 2 each). It has served me well over the years.

It somewhat reminds me of a fishing tackle box I had many years ago, though mine was metal. But the design/appearance are very similar.

I very much appreciate your regular use of FFWD. I can be so tedious watching videos that show every action in real time.

I made one of these 17 years ago based on a plan in Fine Woodworking. The author had made his to be a worksite tool box. His was made from Paulownia. I couldn’t find Paulownia in East Tennessee so I used red oak and Baltic birch. It was my first set if dovetails, I didn’t bother to cut any practice ones…I should have..but they look pretty good I must say. I added a set of drawers on the inside and used the inside of the door for saws, etc. The bottom holds 3 hand planes and a 2 ft. level protected under the door hinges. I still have it.

I made two of these toolboxes about 15 years ago — one for each grandson at age four. I made the toolboxes of walnut, finished them with several coats of oil finish, and then added brass campaign hardware to the corners. The tool boxes turned out beautifully. I then stocked them with a tool kit appropriate for young children and gave them as birthday gifts. Nice projects; nice gifts.

Great work on the videos!

Thanks.