We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

At my day job as wood-shop manager at Robert Lighton Furniture in New York, I often need to fine-tune furniture parts before I pass them over to our skilled sander, then on to the finishers. We design our furniture in the United States, but have them hand-made from reclaimed wood in India, mainly from old buildings posts and beams. In most cases the furniture arrives to our Brooklyn shop and requires only minor adjustments and fittings such as hardware, shelving, and leather-tops on both desks and cases of drawers. Sometimes whole components have to be reconstructed due to damage during shipment or because of a client’s specific requests that can not be addressed by the Indian craftspersons. This week I worked on an tall teak armoire. I anticipated that it would be an easy job: adjusting the drawers, installing the lock and the escachuin, and adjusting the doors and the hinges. What I did not expect was a surprising discovery: planing teak can wreak havoc on your plane’s blade and sole. I have been working with teak for a few years now and over time I noticed that it shortens the normal life span of the keen edge on my tools. In my view, teak resembles and feels like the tropical equivalent of our walnut in terms of its look and density. But unlike walnut, teak has a negative effect on our edge tools. Over the years I have learned to expect shorter intervals between honing, and I read that this is because teak is embedded with small particles of silica.

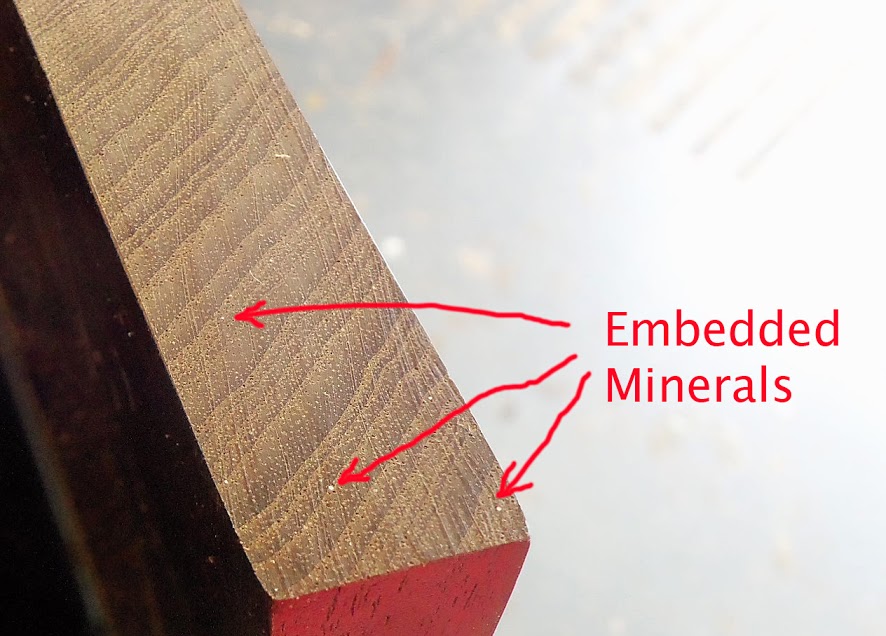

O.k. fast forward to Wednesday of this week. I finished installing the lock, adjusting the drawers and the door hinges. The only thing left for me to do was to trim the door stiles which were too proud and did not allow the doors from closing properly. I pulled out my Lie-Nielsen low angle block plane and started planing the teak’s end grain. At first it all went well but then I started feeling that the plane and the surface it left behind was not doing that well. I saw lines on the end grain and I thought that perhaps I ran into a small metal particle too small to see, but big enough to nick my blade. So I lifted and turned the plane over and I could not believe my eyes. The plane’s sole was scarred with cris-cross scratches, as if I was planing No 80 grit sand paper. After giving the teak end-grain a close look I saw the cause of all this. Small white particles of minerals (or the like) poke-a-dotted the surface. These were undoubtedly the guilty party in all of this. Are these “gems” the infamous silica particles I have read about? Or, perhaps I discovered a new species of wood contaminant un-known to the world of woodworking science?

I really don’t know the answer, but I do know that I had to spend a lot of time sharpening and honing my plane’s blade after this incident and I also know that from now on from now on I will look at teak in a totally different way than before. Those white minerals are like the icebergs that sank the Titanic. We should take their threat very seriously.

Here is the Armoire I worked on:

And here are picture of the minerals and the scratches they caused:

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.