We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The difference between a good hammer and a great hammer is significant. Most hammers at the hardware store are but one step above a rock tied to a stick. As a result, I’ve always bought vintage hammers with wooden handles, which are cheaper, better made and have the right details for a furniture maker.

Now Gramercy Tools, the brand of Tools for Working Wood, in Brooklyn, New York, have come out with two new American-made hammers that have many of the right details that I like. While they are more expensive than your typical vintage hammer, I bought a pair of the Gramercys to give them a try and a close look.

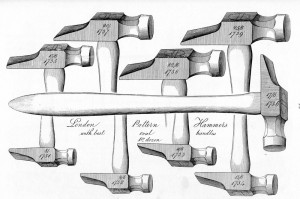

First, some background on the form. There have always been hundreds of different patterns of hammers for different trades. Check out my visit to the Fulton’s hammer museum here for an eyeful. Sometimes a hammer is named for its job – framing hammer, slater’s hammer etc. Sometimes it is named for some geography – London-pattern, Lancashire etc. The boys and girls at Tools for Working Wood took the latter route – hence the name: Kings County pattern. So points for the name.

The tools are “cross-pane” or “cross-peen” hammers, so named for the flat duckbill bit sticking out the back of the head. The pane is used to start tacks, brads and nails that are pinched between your fingers. You’ll also find a dozen other uses for the pane, such as knocking the iron in a moulding plane firmly against the wall of the escapement. So kudos for the pane.

The striking face of the Kings County hammers is domed – a nice feature for furniture makers. The dome allows you to easily sink a nail’s head flush to the surface without dinging it. This is harder to do with flat-faced hammers. So yea for the dome.

According to the designers of the hammer, the heads are differentially hardened, like a lobster. That means a ductile and soft interior and a harder exterior. This is one reason good old Maydole hammers are a joy to use and prized. This feature makes the hammer a long-term survivor. Again, points to Gramercy.

The handles are traditional hickory and octagonal in cross-section. I prefer octagonal handles, but the Gramercy hammers are a little skinnier than the hammers I use. The larger Gramercy weighs almost 12 ounces and has a handle that is .95” x .71”. My equivalent Brades is 10.2 ounces and has a handle that is 1.15” x .93”. The difference might seem slight, but it is quite noticeable. The slender handles don’t surprise me. Whoever designs the Gramercy tools favors slender handles and totes – take a look at the company’s dovetail saws.

The other thing that catches my eye on these hammers is the narrow neck below the head. The company says the handle is “deceptively strong,” so I will reserve judgment. I will say that I have twice broken the arms of the company’s bowsaw, which is also hickory. It’s a great saw, but you do have to be careful with it. I’m not really concerned about the little Gramercy, which weighs 5.6 ounces. Its .35” x .42” neck probably won’t see much abuse, as it is intended for headless brads, tacks and adjusting your other tools. The big Gramercy has a neck that is .45” x .45”, and some people will use this for driving 4d and 6d nails for carcase construction. My Brades, by way of comparison is .5” x .75” at its narrowest and is strapped in iron.

This raises an important point: I wouldn’t use my Brades or the big Gramercy for either 4d or 6d nails. They are too slow. For carcase construction, I much prefer a hammer with a 16 oz. or 18 oz. head. It drives 6d nails in half the number of strokes of the Brades or big Gramercy.

So all this is to say: If you do buy the Gramercy hammers, which are very nice, use the small one for adjusting tools and driving small brads. Use the big Gramercy for driving finish nails, such as cut headless brads for attaching trim, and clout nails for attaching cabinet backs. Asking it to drive big 6d nails is out of its pay grade in my opinion.

This weekend I put both hammers through their paces driving a bunch of wire and cut nails into dry and hard yellow pine. I found both hammers to be well-balanced and responsive. The domed faces are absolute perfection. And the decorative filework on the heads is over the top and gorgeous. I wish the handles were a tad thicker to fill my hand, but that is my only significant complaint.

It takes an immense amount of guts to make a hammer that requires a lot of handwork in the United States and compete against hammers that cost a small fraction in comparison. And so for that, Tools for Working Wood earns my respect and a salute. If you can afford them, like the way they look and like to support domestic manufacturing, then head over to Tools for Working Wood to get on the waiting list for the next batch.

— Christopher Schwarz

Love nails? Welcome to the club. I wrote a lot about nails in Woodworking Magazine, which we published from 2004-2009. You can own all 16 issues on a searchable CD for less than $40. It’s a great bargain on a load of pure woodworking information. Visit ShopWoodworking here for more information.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Just how many hammers does ONE man really need to drive a nail ??

I have two (2) — just in case one walks off. But buy a good one !

The Guy that built my house had two too ….Good house.

Like wives, I can’t use but one at a time or the first one will leave.

Ever notice how many pencils you carry around ? Get one good one.

Then, Maybe I just don’t think about hammers as much as you do.

Let’s talk about something useful, fruitful, educational to all for a change.

No more hammers or work benches please !

Bones

I got to try the prototypes while visiting Joel’s store last August and must say it was exciting to be given the chance to drive some nails with a newly hand-made hammer. I like the slender handle which reminds me I am not using a framing hammer :). Congrats to Tools for Working Wood for the new Kings County pattern hammers!

Daniel

On the naming of hammers: you’ve missed out the Birmingham screwdriver (aka Liverpool screwdriver, Manchester screwdriver etc depending on your local prejudice in the UK.)

I am surprised that in your review you did not consider that having a slender handle on the hammer was actually a good thing.

Nice to know there are quality hammers with slender handles. A hammer that fits a man’s hand is not very comfortable or effective in a woman or child’s hands.