We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

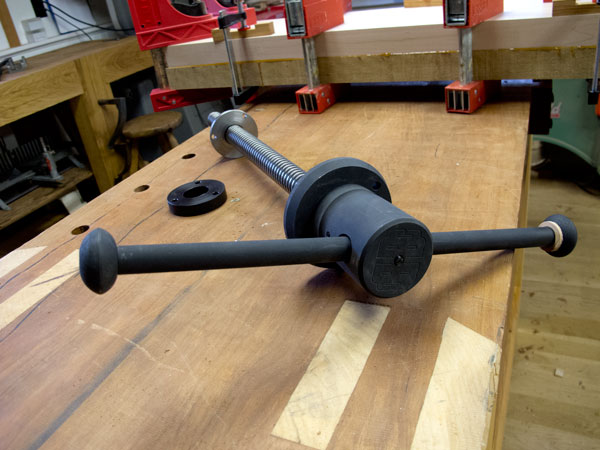

I started making the wooden vise chop for a new leg vise for my Holtzapffel workbench (featured in “The Workbench Design Book”) using some crazy new hardware from Benchcrafted: the Classic vise screw and the Crisscross.

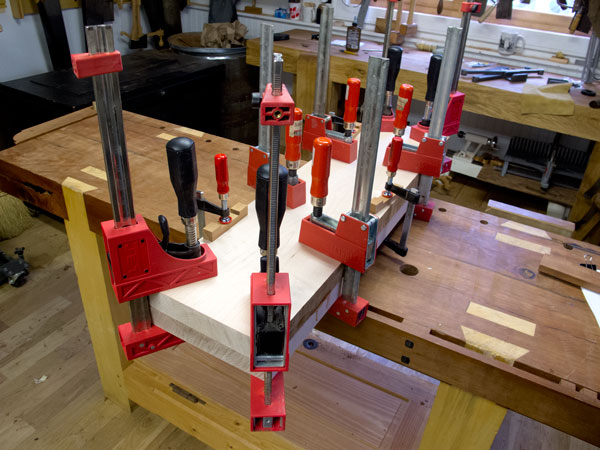

The only downside to the Crisscross part of the assembly is that you need a vise chop that is quite thick – 3” is a good thickness. I don’t have any maple in my shop that thick, so I laminated the vise chop from two 1-3/4”-thick slabs of soft maple.

I prefer soft maple (whenever possible) because it’s cheaper, easier to work and (in my experience) more likely to be figured. Plus, few people can tell the difference between soft and hard maple. They are both plenty hard.

After laminating up my chop, however, I realized I’d made an error. I used hide glue to laminate the chop instead of yellow glue. The problem is that I have a SawStop, which has flesh-detecting technology. Even when hide glue is fully cured, it sets off the Saw Stop. It’s like having a little layer of hot dog inside.*

So I’ll have to finish shaping the chop with a handsaw or a band saw.

— Christopher Schwarz

* This is a total lie. It’s actually like having a layer of horsemeat inside your lignum. Wait. Aren’t hot dogs horsemeat? And fly parts? I forget. Oh, and hide glue doesn’t set off your SawStop, either.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Chris, I am starting to put together the materials to make a Holtzapffel bench according to your design, and this post brought up a question. Did you find any downsides to the big twin screw vise after using it for a few years? Or is this retrofit just an opportunity to try out some nifty new vise hardware? Thanks a lot!

This post is hilarious, you got chops man. I love a good joke!

One thing leaves me pondering though; I was about to give hide-glue a try,- now I am hesitating.

Where you serious about using yellow glue instead for this application?

IS hide-glue reversible on a chop this size ?

Just use the key and deactivate the system to make those cuts. when you finish reactivate the system.

Good point about soft maple and figure. I prefer to use soft maple for painted millwork, and out of every load I find a handful of figured boards, with 2-5 top notch ones for every 250 bf. As it doesn’t machine cleanly through the shaper and moulder, employees avoid it as “defects” because of the extra sanding it will cause them. My “stash” pile currently has 200 bf of curly “defective” maple.

Chris, you could have used the bypass on the SawStop!

Michael

Looks like Chris added a door to the bottom of the bench. And I see he added the tool rack as well.

Chris doesn’t need my defense, but I guess 7-thumbs knows it all (though the name might lead one to think otherwise).

I for one, probably would have wondered if building the vice from lamination would produce a weaker vice. And two, that soft maple will do if hard maple isn’t available, price or locale being a factor. Both questions are now answered. I want to see what other issues Chris runs into on this addition, as benches are something he’s put considerable time and effort on, and has some very useful insight into their construction and modification.

If folks aren’t interested in a particular editors post, why waste time complaining when there’s so much else here to read? Being a troll is something 14 year old boys do. It’s unbecoming behavior for adults (or anyone for that matter) here.

Horsemeat and flys? I was always told it was lips and a$$ holes. 😛

What was the point of this article? Nice to have a job where you’re paid to write this kind of stuff. Is PW getting desperate for really informative online articles?

Aren’t hot dogs horsemeat?

Well, perhaps you should use a Halal/Kosher Sawstop.