We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Let’s continue the story of my student Chad’s coffee table built at a live edge class at Peters Valley.

Let’s continue the story of my student Chad’s coffee table built at a live edge class at Peters Valley.

In this entry I will show how we found a convenient way to trace the shape of the shelf, cut it and connect it to the legs.

Because the shelf was intended to span an irregular trapezoid-shaped gap between the four legs, it had to be custom cut. We had to devise a way that would ensure maximum accuracy in tracing its dimension and cutting its shape.

First, Chad cut a piece of brown paper and trimmed it so it fit over the four mortises. Then he tacked in the legs – which pressed and stabilized the paper. Next, he traced the shape of the shelf and cut the paper pattern using a ruler and a knife.

Once the pattern was ready he laid it on top of the walnut slab, traced the perimeter and sawed the shelf off along the tracing lines.

Chad used a Festool Domino to cut four mortises in the face of the lower portion of each leg and in corresponding mortises at the end grain edges of the shelf.

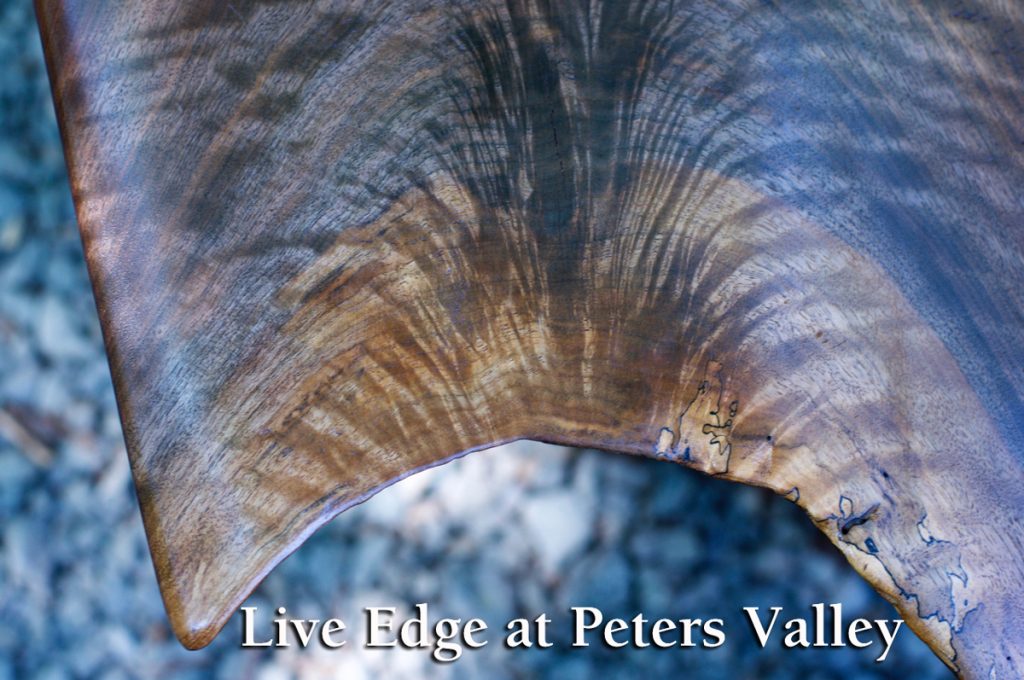

After gluing all the parts together the job was done, short of the finish work which he completed at home. This piece truly celebrates live edge design in its essence, as attested by the images below.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.