We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Coming (very soon!) in our November issue is an article by Willard Anderson titled, “Make a Shapely Bowsaw.” Unlike today’s commercially available models, the antique example on which Bill based his saw has tapered handle holes through the arms, which helps maintain the sawing angle on the blade. You’ll find out how to make your own (and see a very cool X-ray of the handle-to-arm connection), and you’ll also read a bit about of the bowsaw’s history, and that the handles were made by the commerical firm of James Howarth and Sons (the curvaceous arms were likely user-made).

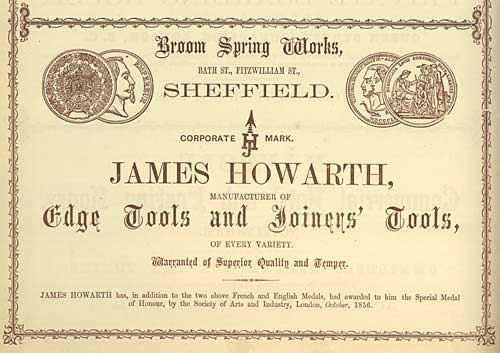

There was not, however, room in the print pages to write much about Howarth, so Bill has provided the image of Howarth’s trade card (above) and the information below about this highly respected 19th-century toolmaker and businessman.

Look for Bill’s story in the November 2011 issue – the digital issue will be available to subscribers the week of Oct. 3, and print issues will begin appearing in mailboxes the following week (both print and digital copies will be available at ShopWoodworking.com). The November 2011 issue will available be on newsstands Oct. 20.

James Howarth was born on the 19th of December in 1811 into a typical hard-working family. At the age of 12, he began working as a “second hand,” or “striker,” alongside his father William who was employed as an edge toolmaker by Mitchell Brothers in Furnival St. Sheffield. Howarth was clearly a devout Christian, as by his 19th birthday, he is recorded as being a lay preacher at his local Wesleyan Methodist chapel.

In 1832, Howarth was promoted to works manager and two years later formed a partnership with Henry Taylor in establishing the business of Taylor and Howarth in Fitzwilliam Street, Broomhall, Sheffield. The company became principal manufacturers of light edge tools, restricted in the first instance to the home markets, but the trade of the firm rapidly extended until they had direct business connections with leading continental states such as Canada, Australia, China and other distant markets. The partnership with Henry Taylor was dissolved in 1842.

James Howarth and sons went on to become exhibitors at the London Exhibitions 1851 and 1862, and in Paris in 1855, and received on each occasion prize medals of the first class. The Universal Society for the encouragement of Arts and Industry founded in 1851 reported on the goods exhibited at Paris. This society awarded its first-class prize medal to Howarth for excellence of his tools and elected him an honorary vice president of the society – an honor paid to no other British Manufacturer.

In 1857, joiners’ tools were added to the company’s line after it had moved to Bath Street at Broom Spring Works, Sheffield. In 1863, the firm became James Howarth and Sons, and it set up a steel division in Eyre Street, Sheffield, that enjoyed an excellent reputation for its steel quality.

James Howarth and his sons were all practical men and personally supervised all departments of their manufacture, giving close attention to the general workmanship as well as to setting and finishing their products.

The edge tools they made were from some of the best iron and steel available, while joiners’ tools such as squares, bevels, spokeshaves, gauges etc., were made chiefly of ebony and other expensive woods combined with brass and or steel. The company produced hammers from 1 ounce to 25 pounds, in an infinite variety of shapes, to meet the most varied requirements. The manufacture of skates was also one of the special features of Howarth’s business.

Using the very best materials and employing the most skilled labor, James Howarth and Sons produced goods of the very highest standard and had a reputation for excellence in the most distant markets. Upon the death of James Howarth, the firm was managed by his four sons James, Samuel, Edwin and John Howarth. The firm was discontinued in 1913, and its mark was acquired by Robert Sorby and Sons in 1922.

— Willard Anderson

From “The Illustrated Guide to Sheffield” (available in full on Google Books):

From “The Illustrated Guide to Sheffield” (available in full on Google Books):

Messrs. HOWARTH AND SONS.—Among leading manufacturers of edge tools and joiners’ tools are Messrs. James Howarth and Sons, of Broomspring Works, Bath-street. The business was commenced in 1835, by the present senior partner, who was joined by his sons in 1863. Messrs. Howarth manufacture light and heavy edge tools of all kinds, including every variety of joiners’ tools, hammers, skates, augers, &c. Restricted in the first instance to the home markets, the trade of the firm has rapidly extended, and they have now direct business connections with leading continental states, Canada, Australia, China and other distant markets, as well as with home consumers. They were exhibitors at the London Exhibitions of 1851 and 1862, and at Paris in 1855, receiving on each occasion prize medals of the first class. The Universal Society for the encouragement of Arts and Industry, founded in London in 1851, reported on the goods exhibited at Paris four years later. This society awarded its first-class prize medal to Mr. Howarth for the excellence of his tools—an honor paid to no other British manufacturer — and elected him an honorary Vice-President of the Society. Messrs. Howarth are all practical men, and personally superintend all the departments of their manufactory, giving the closest attention to the general workmanship as well as to setting and finishing. Edge and joiners’ tools, though made for the use of the same class of workmen, are separate and distinct trades. The edge tool, which is mostly a cutting tool,] is made of iron and steel combined, or of solid steel as already described ; while joiners’ tools, such as squares, bevels, spokeshaves, gauges, &c., are made chiefly of ebony and other expensive woods combined with brass or steel. The manufacture of skates is also one of the special features of Messrs. Howarth’s business. They make hammers from one ounce to 25 Ibs each in weight, and of almost infinite variety of shape to suit the most varied requirements. They also manufacture large quantities of steel ” toys,” including pincers, pliers, &c.—a branch in which they are almost the only Sheffield house engaged. Using the best material and employing the most skilled labor, Messrs. Howarth produce goods of a very high class, and have made a reputation in the most distant markets. They are also largely engaged in the steel, file, saw and other kindred trades. Our illustration shows the processes of forging and grinding at their works.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Most Excellent! I have a handful of Howarth tools and all are of the best make. These I’ll never sell off, they stay with me.

Tremendous!