We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

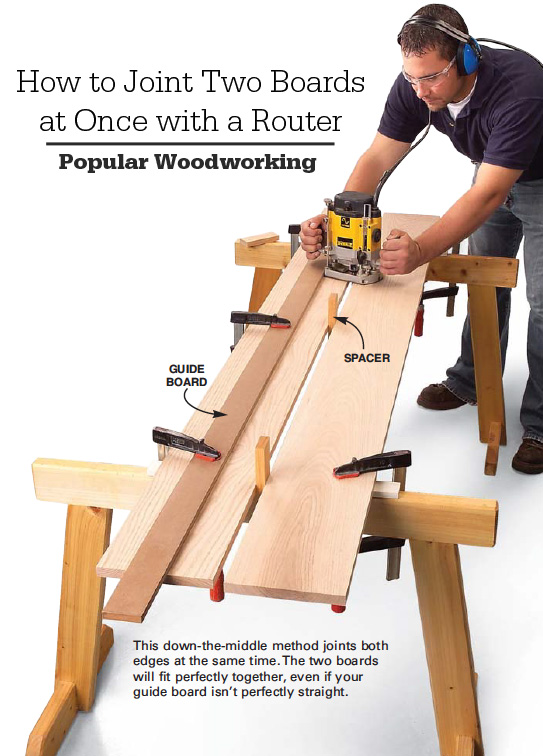

You can use a router to joint two boards at once. This is a really handy trick if you don’t have a long-bed jointer or you don’t have a jointer at all, and you’re working with really long stock.

The trick is to rout both boards at the same time, so the edges mirror each other. Bowed or not, they’ll always fit tightly. To set this trick up, mill three spacer blocks to 11/16 in. thick. Clamp the boards to a pair of sawhorses with the spacers between them.

Chuck a 3/4-in. bit in your router. Clamp the guide board so the bit takes an equal amount off both boards, about 1/32 in. Ride the router tightly against the guideboard, removing the spacers as needed. Any deviation or wandering from the router will be mirrored on the opposite board, providing a perfect fit.

– This trick first appeared in American Woodworker.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Amazing……..the efforts some people will go thru to avoid using a hand plane.

For as long as I live I will never understand why someone would want to work wood with a jointer. I can almost understand folks who prefer to use hand planes (almost). But all these work arounds with planer slides, circular saw jigs, and this contraption, are a recipe for frustration. Jointers aren’t sexy like systainers and are not ubiquitous like a tablesaw, but, frankly, woodworking was not fun until I bought one.

I’ve used this technique ages ago (as with all good tips, Family Handy’s AW borrowed this tip from somebody else), and experienced mixed results. I think the problem has something to do with setting and holding the gap: too little, and the bit doesn’t touch both edges; too much, and the bit works too hard. And if either board shifts, the cut is toast.

Consider the times…Back when the tip first appeared, higher powered routers and smooth cutting carbide bits weren’t as available as they are today. Nowadays, I’d try stacking the boards, clamping the straightedge on top (set for a super-light cut) and skim-routing both edges. (Using this method, the joint should fit nicely even if the straightedge isn’t perfectly straight.)

Option 2- Thanks to carbide-tipped blades, you might be able to obtain a glue-ready edge straight off the table saw. If the fence-side edge isn’t straight enough, try attaching on a straightedge with tacks or tape.

I see a several issues here:

1. If you have a router with a flat side, use it to register the router. If that guy rotates the router clockwise just a little bit, disaster!

2. The spacers should only be needed during setup. Once the boards are clamped, the spacers can be removed.

3. The initial spacing is fine, but if your edges are not relatively straight, it may take a second pass, after resetting the spacing.

This method would seem to work fine as long as the spacers aren’t deflecting either board, i.e. wedged tightly netween them. If they are then the boards will move when the spacers are removed, messing up the rest of the cut.

It seems to me that the spacers are unnecessary and should be left out. If anything, use 3/4″ spacers (maybe T shaped so they don’t fall out) BEHIND the cut for stability.