We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I’m editing the November 2013 binder today and have just turned the page to the first article in the “feature well” (the section in the middle with no advertising, that follows the up-front columns). And I decided I needed a break before tackling it (hence this blog post).

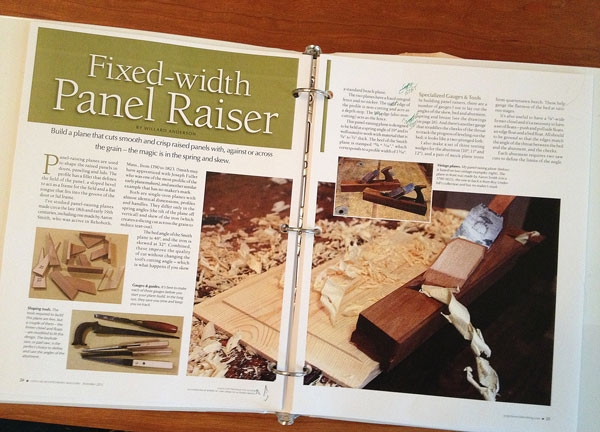

As always, the first feature is the cover story – and for November, it’s a detailed, step-by-step article by Willard “Bill” Anderson on making a fixed-width panel-raising plane. (You may recall Bill’s excellent “Make a Shapely Bowsaw” from the November 2011 issue and “Rule Joints: by Hand & Power” from the August 2012 issue – or perhaps you’ve had the pleasure of a class with him at The Woodwright’s School.)

“Fixed-width Panel Raiser” is a complete brain twister – and no doubt many some people will think we’re crazy for printing it. (Heck – I think we’re crazy for printing it…but I’m a wild and crazy gal. Once in a very great while.) This will, I think, be the most challenging build we’ve ever published (despite it’s relatively small size).

I now have a much richer understanding of how skew and angles combine to make a blade cut wood and reduce tear-out. And I now have a greater understanding of why custom-built planes command a high price; every penny of that price is earned. (That, by the by, is an excellent reason to learn how to build your own.)

I don’t know how many of you will actually make this panel-raising plane (though I hope you will, and that you’ll share pictures of your plane). And I don’t know if I’ll ever build it. But I do know that reading and editing the article several times has scrambled my neurons for the better.

I hope you’ll feel the same. Let me know in mid-October when the issue comes out.

Now that’s quite enough procrastination; back to editing.

— Megan Fitzpatrick

@1snugthejoiner

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I too would like to commend the author for the article and Popular Woodworking for printing it. It is so refreshing to be challenged! I have started trying to make this plane, hoping like others, to improve my woodworking skills.

That said, I am wondering if anyone else is as confused as I am by the drawings. Looking at the “Plane Schematics, TOP” on page 27, for example, the angle labeled “Skew” is shown as being 32 degrees, as also discussed in the article. I know and accept that the drawings aren’t advertised to be to scale, but that angle does not look as though it is properly defined. From the convention I remember from HS geometry, the drawing indicates that this angle is measured from the HORIZONTAL line (the long edge of the plane) to the bed, but the reality seems to be that the ‘skew’ refers to the skew from the perpendicular (a VERTICAL line not shown) to this horizontal plane. Shouldn’t the angle indicted in the drawing actually be 58 degrees? The same question applies to the SKEW GAUGE on page 26.

Can anyone confirm my interpretation or, if anyone has actually used the drawings to build his/her own plane, that the drawings are correctly labeled? I am only getting started and this little issue is making me lose confidence in my ability to complete this project.

Thanks!

Holy cow! I can see why your head is hurting. I just got my November issue of PW with the panel-raiser plane. I’m a retired engineer and my head is also hurting, but this won’t keep me from building this plane. Like I said earlier, that I completed a half set of H&R’s plus two snipes bills and they will seem easy as compared to this panel-raiser plane. Fortunately for me, I have all of the recommended tools plus the two floats that I also made for the H&R project. It will be interesting to see the gallery of pictures of subscribers panel-raising planes.

The beauty of the printed word is that thoughts, processes, and techniques are not as likely lost with the passage of time and memory. Therefore publish with the knowledge you have provided information which still may be read and enjoyed perhaps centuries from today.

I just finished making a half set or H&R’s plus a pair of snipes bills, so why not give a panel raiser a try? Oh, by the way, I don’t recommend using osage orange for boxing it is a real pain.

There is a block of oak sitting in my basement already reserved for this.

If only they would fix the VIP program, I might get to see that issue…

Still out of stock Ma’am.

Best regards,

Albert A Rasch

Thanks for this Megan it looks like it will be great! If you print it, we will follow!

I have two (left and right) panel-raising planes made by Leon Robbins at Crown Tool before he passed away. I bought the first one in the 1980’s directly from him out of his converted back porch workshop and I got to see the construction and sharpening jigs–I wish now that I had thought to ask if I could take pictures. His planes were laminated with a hard maple core and sides out of curly maple, all stained a nice dark reddish color. They work wonderfully! They do not have a nicker so on some woods, you need to run a cutting gauge around the panel first.

It doesn’t look like the Jimmy White, the new owner at Crown Tool is making panel raisers anymore, which is a shame. I would imagine that CNC grinding the blades would be the way to go now–the wooden parts would be fairly easy to make in the laminated style of plane.

–Brian

Bring it!!!

Sounds like a great article, can’t wait to give it a try

Given what a good panel raiser typically goes for on eBay this may be the only way I will ever be able to have one. I guess I need to start scrimping and saving for some good plane makers floats. I’ve been looking for a good excuse to buy some. Looks like I found it …

I’m looking forward to getting that issue. Thanks for the post.

Jim

Come on October!

This looks fantastic, I’ve been thinking about making one of these for some time now.

Is this made from a laminated blank, Krenov-style, or is it made from a solid billet?

I’m sure I’ll build it. A few years ago I started using an old Type 45 Stanley to make beads on the edges of various projects, and there’s great satisfaction making these types of decorative shapes by hand. It’s a whole different esthetic that gives me a sense of accomplishment and pride in my woodworking skills.

I’m up for it, I’ve wanted to build a panel raiser for a long time, and to get the how to from Bill Anderson and Pop wood is just the ticket. I hope I can understand it 🙂