We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Sanding sealers. These are available for alkyd varnish and lacquer for the purpose of speeding production because these finishes gum up sandpaper; sanding sealer powders when sanded. To understand this product, put the emphasis on “sanding,” not on “sealer.”

To master finishing, you need to understand the basic terminology.

All technical fields have their own vocabulary. You’ll have difficulty mastering any technical field without understanding its vocabulary. Here are some of the most commonly used finishing terms and their meanings.

Sealer (sanding sealer) is the first coat of any finish. The first coat penetrates, dries, and seals the pores so the next coat of finish (or any other liquid) has difficulty penetrating into the wood. The sealer coat also locks raised wood fibers in an upright position causing the surface to feel rough. To achieve a smooth final finish, you should sand the sealer coat smooth before applying additional coats. Special sanding sealers are

made for lacquer and alkyd varnish that are difficult to sand. Sanding sealers don’t clog sandpaper as easily as these finishes.

Finish is a substance that changes from a liquid to a solid after it has been applied to the wood. The purpose of a finish is to protect the wood and enhance its appearance. By adding colorant to a finish (usually called a binder in this situation), you can make a stain, glaze, toner or paint.

Film finish is any finish that can be built (by repeated applications) to a hard, thick layer, or layers, on top of the wood. The key requirement for a film finish is that it must dry hard. This is in contrast to so-called “penetrating” finishes, such as oil, which don’t dry hard. Alkyd and polyurethane varnish, shellac, lacquer, water-based finish and catalyzed (two-part) finishes are all film finishes.

Washcoat. A washcoat is a highly thinned finish applied to blotch-prone woods (see top half of birch panel above) to partially seal the pores to reduce the blotching. A washcoat can be made from any finish. Wood conditioner is a washcoat made by thinning oil or varnish. The trick for having success with it is to let it dry thoroughly before applying a stain.

Washcoat is any finish thinned with two or more parts thinner to partially seal the wood and prevent uneven stain penetration (blotching) on soft woods such as pine and tight-grained hardwoods such as cherry and birch. So-called wood conditioners are oil or varnish washcoats. To be effective these (and all) washcoats have to be allowed to dry thoroughly before a stain is applied. A washcoat can also be used between coloring steps with minimum build to prevent the colors from

running together.

Thinner (mineral spirits, naphtha, lacquer thinner, alcohol, water) is any evaporating liquid that can be used to thin a finish, stain, glaze or pore filler to make application easier.

Solvent (mineral spirits, naphtha, lacquer thinner, alcohol, water) is any evaporating liquid that dissolves a dried finish, stain, glaze or pore filler. Often a solvent for a solid substance is also the thinner for that substance in liquid form.

Sheen. The degree of gloss a completed finish produces is determined by the sheen of the last coat applied. This is obvious in this example where I applied two coats of satin varnish to the left half of the panel, then one coat of gloss to the left quarter, and two coats of gloss to the right half of the panel, then one coat of satin to the right quarter.

Sheen is the degree of gloss in a dried finish. Most film finishes dry to a gloss sheen unless flatting agents (gloss-reducing solid particles) are added. Semi-gloss, satin, matte and flat varnishes, lacquers, and water-based finishes have had flatting agents added. These finishes must be stirred before use to put the flatting agents into suspension.

Stain changes the color of wood. There are two types of colorant used in stains: pigment and dye. Pigment particles are opaque and resemble colored earth. They settle to the bottom of the can and must be stirred into suspension before using. Applied to wood, pigment lodges in recesses, such as pores and sanding scratches, large enough to hold it and remains there after the excess stain is wiped off. Built up on wood, pigment obscures the wood like paint. To glue the pigment particles to the wood, a binder (oil, varnish, lacquer or water-based finish) must be included in the stain. Dye is transparent. It dissolves rather than suspends in the liquid. Once dissolved, dye remains in solution. It can be combined with a binder, or simply dissolved in a liquid and applied.

Glaze. A glaze is a wonderful decorative product used to produce all sorts of effects, in this case definition and depth. The procedure for doing this is called “glazing,” and is always done over a sealed surface so the glaze can be manipulated (partially wiped off) without staining the wood.

Glaze is a stain that has been made thick and resistant to flow so it stays where you put it, even on vertical surfaces. Gel stain, for example, makes a good glaze. You can use a glaze to darken or change the color tone of wood after the wood has been sealed. You can leave a glaze in the recesses of carvings, turnings and moldings to give the appearance of age and three-dimensional depth. You can feather out a glaze to highlight certain areas, such as the centers of cabinet doors. Or, using special glazing tools, you can make patterns in a glaze that resemble wood grain or marble. When the glaze is dry, protect it from being scratched off by applying one or more coats of a clear, film finish.

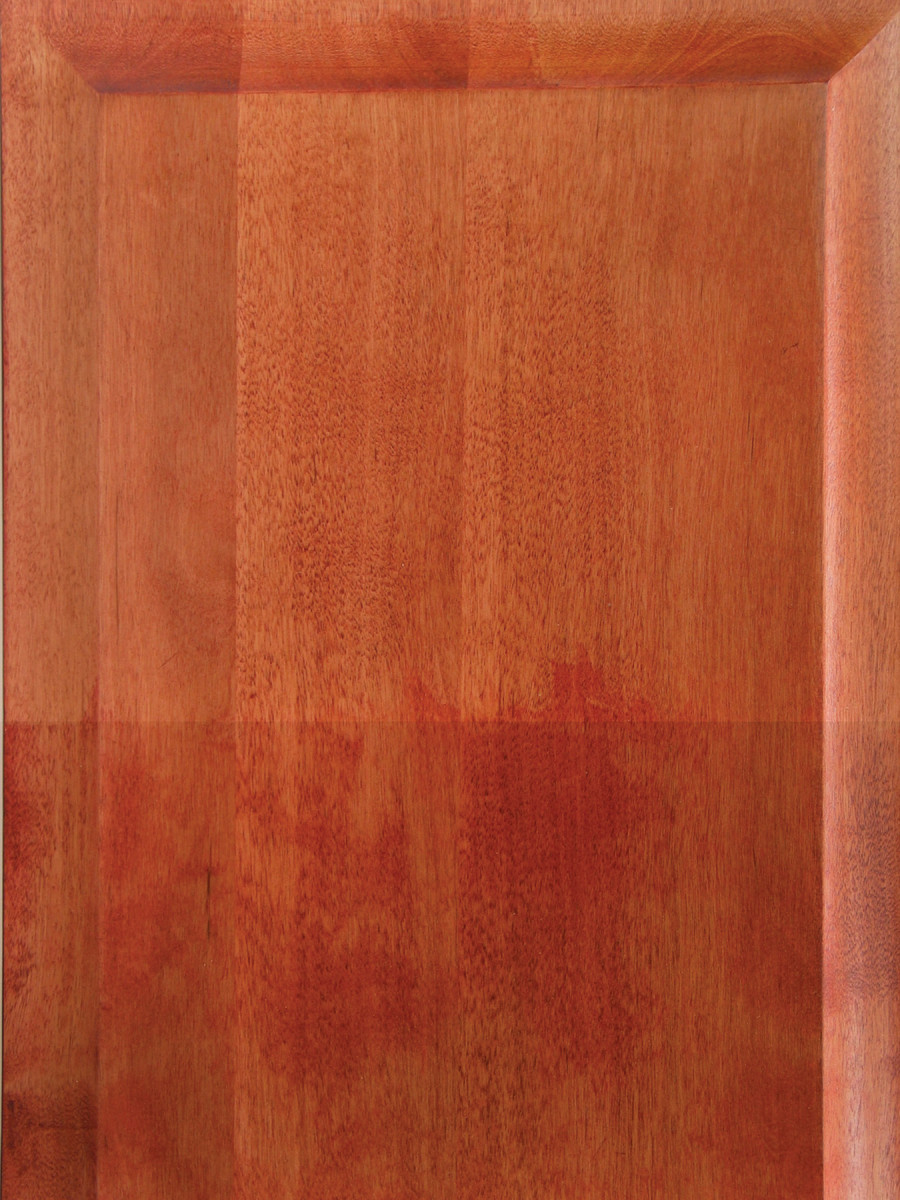

Pore filler. Filling the pores of large-pored woods such as mahogany and walnut creates a more elegant look, especially in a raking light. The filling can be done directly on the wood to stain and fill in one operation, or over a sealed surface, as I’ve done here (right half).

Pore filler is essentially a glaze with silica (fine sand) added to provide bulk. Pore filler is used to produce a mirror-flat effect by filling the pores of porous woods such as quarter-sawn oak, mahogany and walnut before the application of a film finish. Pore filler doesn’t take stain well, so pigment should be added before application. You can apply pore filler directly to raw wood to fill and stain in one operation, or you can apply a different colored filler to a sealed (and stained) surface to highlight the pores, as I’ve done on the right half of the panel.

Toner is finish, usually lacquer, with dye or pigment added and sprayed. To provide better control, thin with up to six parts thinner. Toner adds color in very thin layers without penetrating into the wood. Toner can be used to change or adjust a color after the wood has been sealed.

Shading stain is a toner used to change or adjust the color of certain parts of wood without affecting other parts. Shading stains can be used to blend sapwood to heartwood and to highlight certain parts, such as the centers of cabinet doors, by darkening the surrounding areas.

Rubbing and polishing is the procedure used to level the surface of the final coat of finish and raise or lower the sheen. Various abrasives, including fine sandpaper, steel wool and rubbing compounds, are used. Sandpaper removes dust nibs, orange peel, brush marks and other imperfections in the surface. Steel wool and rubbing compounds (fine abrasive powders in a liquid or paste) raise or lower the sheen.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

This is a great reference on finishing! I’ve used almost all of these in my woodworking projects – and introduced myself to dye when I was color matching a complex maple entertainment center. Thanks for sharing.

E.D. Tryon

The Home Woodworker

Very Good lorry transport near me