We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

It’s always fun to attend shows like the recent Association of Woodworking & Furnishings Suppliers event in Las Vegas. Not only do you get a look at new or improved products that are ready to launch, you have a chance to see what’s on the horizon. Yesterday I got a glimpse at two machines that could lead woodworking further in the electronic age.

Next Wave’s Computerized Router Table Fence

The first creative product is a computerized, programmable router fence developed by Next Wave Automation; it will be released exclusively through Rockler starting in late September or early October. Why do we need a computerized, programmable router fence? Well, truth be told, it’s probably overkill for most of us. But if you’re the kind of woodworker who loves technology and wants to create precise and repeated joints, this machine does have appeal. And the price ($599) makes it a reasonable investment for techno-woodworkers.

The Next Wave system uses a tight-tolerance worm drive to precisely move the fence in relation to the bit. To zero it to the cutting diameter of your bit, you first insert a digital touch plate between the fence and the bit. Once the system has locked down that exact distance, you can program the fence for one or more cuts spaced specific distances from your cutter. You can save up to six fence positions in the system’s permanent memory in case you want to come back later and do another run of specific parts.

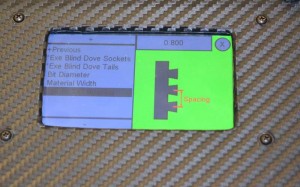

What’s really cool about the system is that it comes with a series of apps that takes the guesswork out of cutting dovetails, box joints and dados. For example, if you’re cutting dovetails and you want to precisely space them on a board, you can simply plug in the diameter of your bit and the width of your workpiece and the system’s program will automatically determine spacing and set up the cuts. You can see the screen readout for dovetail spacing on the adjacent photo.

Now I realize I’m talking heresy to those of us who think spacing out dovetails with a pair of dividers is just fine, thank you. But still, this is a fascinating technology.

The folks at Next Wave say they’ll be adding apps for more operations in the future and because the system has a USB drive, it will be easy to add apps or update system software. They’re also looking at other applications for their fence system, including tying it into a router lift and possible using it on a table saw fence.

TeknaTool’s Smart Drive Drill Press

TeknaTool’s Smart Drive Drill Press

Imagine a direct drive drill press that can run full out at 5,500 rpms with virtually no vibration. Imagine a drill press that can sense if your bit is mis-chucked or your hand is too close to the spindle and automatically shuts down before you or your workpiece is damaged.

TeknaTool demonstrated a prototype of a machine that will do this and more, and the first generation could be on the market in nine to 12 months.

The new drill press uses the DVR Intelligent Variable Speed Drive that TeknaTool has been using so effectively on the Nova Smart Drive Lathe for the last few years. The core is a direct-drive motor with a computerized controller. It can be programmed to start slow to prevent your bit from tearing your workpiece as you begin a cut and then speed up to a predetermined speed as it senses load. It can sense when your bit is about to break through the back of your workpiece and slow down to reduce tear-out. It can tell if your bit is dull or damaged by the resistance it’s creating while cutting. And it can sense and shut down the unit if you’ve accidentally left your chuck key in the chuck or if your shirt sleeve is in danger of wrapping around the spindle.

The system also comes with a program that will determined the right speed for each operation based on the type of bit you’re using and the species of wood you’re drilling. And like Next Wave’s computerized router table fence. the drill press will come with a USB drive so you can upload new programs or software fixes. Here’s a photo showing the digital screen.

The system also comes with a program that will determined the right speed for each operation based on the type of bit you’re using and the species of wood you’re drilling. And like Next Wave’s computerized router table fence. the drill press will come with a USB drive so you can upload new programs or software fixes. Here’s a photo showing the digital screen.

While some of the programmable features seem like overkill to a seat-of-the-pants woodworker like me, even I can appreciate the value of the computerized safety features this system offers. TeknaTool expects to have a direct-drive motor retrofitted onto a belt-driven drill press in nine to 12 months and a fully operational direct-drive drill press in 12-18 months. If all goes well in these applications, the company sees future possibilities for using the technology in table saws and other critical machines.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

MikeyD,

I think you might have misread bsrlee’s post. He didn’t say that the circuitry lasted only a few months, he said that the _production runs_ were only a few months long. After that, you can’t fix anything.

For example, My Beloved and Darling Wife’s iPad 1 works perfectly well, but it is obsolete. She can’t upgrade the applications she uses in her classroom.

OTOH, her old mechanical sewing machine ($800 in 1974) works just fine.

Judging by people’s past experience with DVR lathes (and things like digital sewing machines), when the controller fails you get to chuck the whole machine and buy a new one. The production life of the control circuitry is measured in months and new model boards are usually not compatible with old model hardware.