We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Screw-driven vises are not modern inventions. The earliest screw-driven vise that I know of is this Italian vise that is circa 1300. I am always looking for earlier vises because the screw mechanism has been around since Archimedes, though his screw was originally used for irrigation.

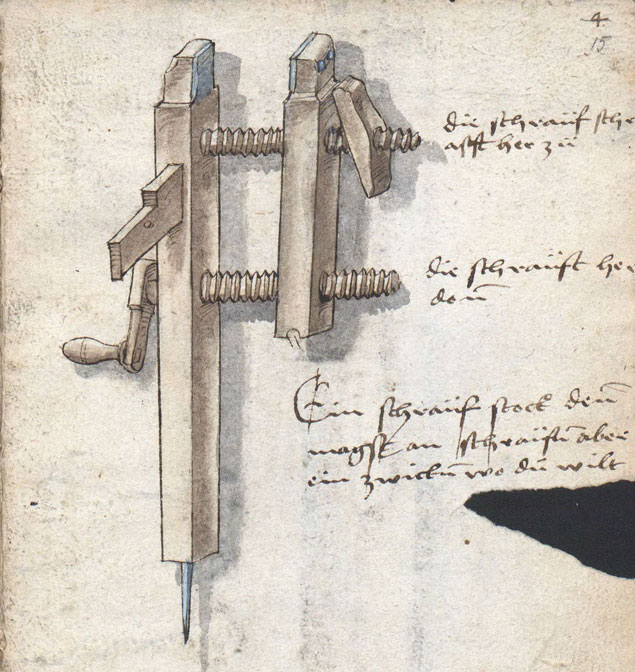

This year I have been delving deep into a codex that was written in 1505 by a patrician named Martin Loffelholz. The 76-page proto-book is filled with hand-colored drawings and descriptions of tools, weapons, locks and even a love potion. With the help of some German friends (thanks Görge Jonuschat!), we have transliterated and translated much of the codex.

I’m currently writing a book about the workbenches that Loffelholz illustrated in the codex, but there is a lot of other great stuff in there that I’m going to share here.

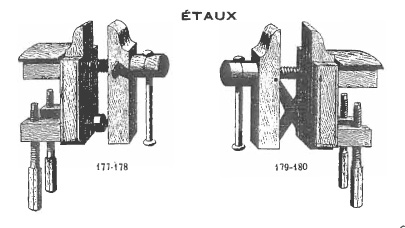

Exhibit A is from page 33 of the codex and illustrates a portable vise that can grip stuff when it is above the work surface. Such a vise is great for close-up work (think: saw sharpening) and was a common fixture in shops in the 19th and early 20th centuries. Check out this version from Old Salem’s workshop. The vise also appears in catalogs from the early 20th century, such as this one from La Forge Royale.

The Loffelholz vise is a bit of a puzzle. Did Loffelholz invent it? Or (more likely) is it something that he saw in a workshop and drew in his codex? The translation of the text that goes with the drawing is as such:

Top text: “This screw tightens from this side.”

Middle text: “This screw from the other side.”

Lower text: “A Vise you may screw or pin to anything.”

So we can say that the vise is portable (the pointy pin on the end of the chop is a dead giveaway). And that it screws from both sides. It reminds me of a handscrew especially in that it tightens from both sides.

Also worth noting: the vise has metal jaws. And the garter-looking thing is a mystery to me. I’m at a loss as to why the vise would need a garter there, unless it was the device that engaged the top screw. But that would be weird because the vise would seem to work better if the top screw were fixed in the front jaw.

The only way to answer these questions is to speculate wildly on an internet message board. No. Strike that. The only way to answer these questions is to build the thing.

The boys at Benchcrafted are building a vise similar to this, which they call their Hi Vise. But it’s more like the modern French versions than the 1505 version. So I might have another project ahead of me that will fail (again) to benefit my family. Eating off a bench – or a vise – isn’t easy.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

I had to google “garter” to see what it meant outside the lingerie world, but didn’t come up with anything, really…? It just seems to mean some kind of elastic band? (English is a second language of mine by the way.) But if it refers to the thing on the top screw it should be a quick-release.

The protruding flat piece on the side however is harder to say something about. It seems so thin it shouldn’t be of much help to hold the vice. Can’t tell from the picture, but is it a wedge of some sort? It lines up just underneath the top screw anyway, maybe it locks the screw? Also, the facing end of the little step on top looks wider than the end closest to the viewer, so maybe it’s tapering that way too? I’m inclined to say it’s an error in the drawing, but if not that wedge/taper could be to fasten it in a slit of some kind.

As you experiment by building this thing, please consider the possibility that the garter-looking thing may be a quick release mechanism.

I just bought two more of your books through Dictum. Thank you for making beautiful things.

The top screw is fixed in the front jaw, I don’t see any other way it could work? The top rear vise would have a clearance hole and then lightly tighten the garter to clamp the piece and then crank with the lower handle to open up and add some pressure to the upper clamp. Sort of like ‘Jorgensen?’ double handle screw clamps. I think that is what you are asking? Do you think your Loffelholz workbench book is going to make him the next Roubo? Thanks for all your crazy hard work!!

I’m wondering if the thread pitch used didn’t let the vice stay tight as you worked and that the garter was really a means of securing the top thread once the work piece was in place to keep the vice from loosening up.

If you needed to extend your gripping ability past the end of your bench you could drive in the spike and use the “garter” to stabilize the top, by clamping it in a face vice on the bench. If that is the answer it generates more questions though. Why the step down? Why the hole that is shown? Maybe unrelated, why the ” cove” groove in the bottom of the other chop? Also are the two lines shown coming down from that just marks without meening? Not sure, but is it possible that the cove is like a modern drafters way of showing a break-away and maybe that side actually is the same as the other jaw?

Hi Christopher,

Sorry to hijack this thread, but I don’t know how get in touch with you a different way. I have a heavy tapered plane iron that is stamped “A LUNESCHLOSS.” I’ve been trying to find some info on a Luneschloss tool company/maker, and haven’t found anything. The closest I can find is a storied Solingen swordmaker, “P.D. Luneschloss.” Any chance you have any information to add?

My guess is the garter thingy is a pistol grip type handle to make it easier to set the spike.

The Loffelholz illustration has left hand threads. Since you didn’t comment on this, is it to mean that this was the common/preferred way to tighten?