We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

As patternmakers are the Jedi Knights of the woodworking world, their workbenches are always a little different.

Usually you’ll find some sort of vise that has more adjustments than usual. A typical patternmaker’s vise is the Emmert. These vises are gorgeous – read all about them at The Iron Hand website. I think these vises are overkill for most furniture-makers, unless you do a lot of sculptural work and need to rotate pieces in unusual ways. Some chairmakers also swear by these vises.

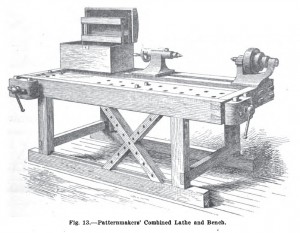

The workbench that holds the vise can also be a bit different. Take a look at the illustration above from the February 1908 edition of Carpentry & Building. This bench incorporates a lathe into its design, which is probably why the bench has sled feet.

There are two details of this bench that are quite interesting for us furniture-makers. First, check out the sliding deadman – sometimes called the board jack. It’s a simple sliding “X,” which is a pretty ingenious design. Because of its wide stance, you wouldn’t have to move it left and right as much as a board jack made from a single plank.

There are two details of this bench that are quite interesting for us furniture-makers. First, check out the sliding deadman – sometimes called the board jack. It’s a simple sliding “X,” which is a pretty ingenious design. Because of its wide stance, you wouldn’t have to move it left and right as much as a board jack made from a single plank.

My only concern would be that the joint at the middle should be perfect and tight. If this joint came even a little loose, I suspect it would wreak havoc with the way the jack slid left and right.

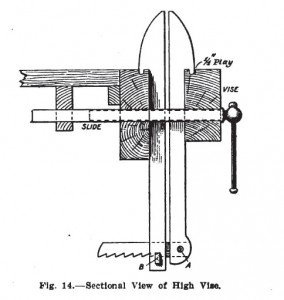

The other interesting detail of this bench is its accessory “high vise.” This is a leg vise that can be installed in a face vise or end vise. It brings the work up higher and allows you more freedom in positioning your work. I’ve seen “high” vises like this in several furniture shops, including the Moravian shop at Old Salem in Winston-Salem, N.C. Read that story here.

— Christopher Schwarz

P.S. Thanks to Jeff Burks for digging up this article for me. You can download the entire 1908 article about patternmaking by clicking here.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

One of the big reasons I subscribe to Popular Woodworking is to read whatever Chris Swarz writes. He does a great job writing a feature or just a comment on something. It is like visiting with an old friend.

Do you know if motor to lathe was mounted on bench behind lathe? I have not been able to find the standard method to drive these pulley type lathes.

I visited a pattern maker a while back because he said he was getting old and wanted to sell all his tools complete as one set in their fitted trays. We had a great eight hours taking out each tool; cranked chisels; cranked gouges; special hand made phosphor bronze detail planes and so many other specialized tools that I had never seen or heard of.

I am glad that he decided not to sell them but at 85 years continue with his woodworking and I hope it keeps him going for many more.

I noticed that a workbench had a lathe onside of the table is it true they did?

I made a high vise from 2×8’s with beveled corners at the top. The have to be just wide enough to be supported by the two gliders in my face vice. The smaller the stuff you work on, the harder the wood.

The high vice is very similar in design to a smaller mild steel one I made in the first year of my apprenticeship 42 years ago. Mine is used in tool making and is meant to sit in the jaws of an engineering vice we called it a secondary vice, it is used to hold small pieces when tool making.

I saw an x-shape deadman on a bench at Sturbridge Village (mid-19th century renactment village in MA) a couple summers ago. But not as wide as the one in the drawing.