We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

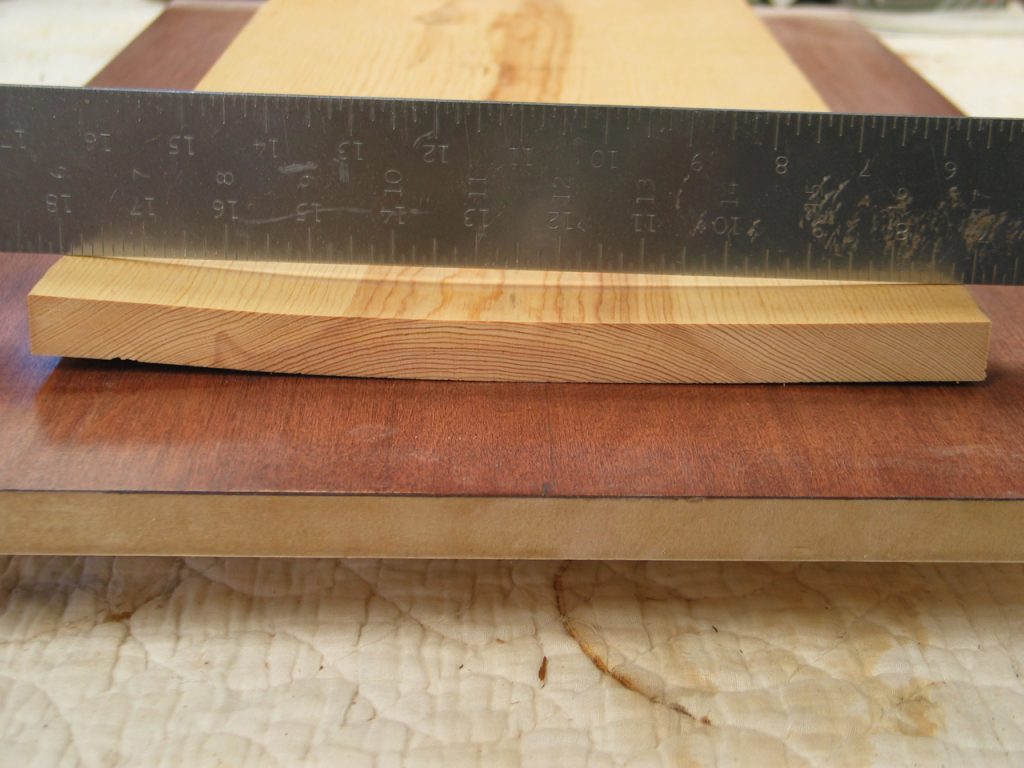

A typical pine board with inadequate kiln drying, so it shrunk and cupped on the outside of the rings as it dried more.

In my last blog post I wrote about the real cause of warps (compression shrinkage) from the continuous wetting and drying out of one side of the wood, whether or not the wood is finished on both sides.

Thinking about this, it may have occurred to you, as it did to me, that it might be possible to correct warps by wetting and drying out the bowed side of the wood. You would cause this side to shrink so the panel would flatten out. So I started experimenting with some warped boards. I shared my experiences with a friend who restores furniture in New England where he sees lots of antique furniture with wide, single-board tabletops. He also began experimenting.

I’m going to describe some of the techniques we developed, but I want to caution that this is a work in progress. We are still learning. We have no hard and fast rules. Correcting warps seems to be more of an art than a science because there are too many variables and no way to have a “control” to compare to. But we have had some successes, and I would say that in all cases we were able to make the warp less than what it was at the beginning.

The first step is to turn the board over so it’s bowed on the topside.

Then thoroughly wet this side with soaking wet cloths to make it swell.

To encourage compression shrinkage of the bowed side, you can add clamps.

Keep the board clamped while it dries thoroughly, which takes many days.

When the wood has dried thoroughly, it should have flattened noticeably.

This is the board after more than a year. The warp doesn’t come back.

You may be able to encourage the flattening by adding weight to the bowed side.

My friend has also tried adding steam to the bowed side to deepen the moisture penetration.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

Hi Bob, interesting stuff! I came across this article when trying to find a solution to my cupping workbench top. It’s reasonably hefty, 1800mm, 600mm, 70mm and made with 50mm wide solid wood planks laminated together. I’ve recently moved it into a new space which is much dryer and it sits under a window and catches the afternoon sun on the top. Only the top is oiled so i would have expected it to cup the other way but hey presto, just as you’ve described it’s cupping upwards! I’m trying to work out a feasible way to use your corrective methods on such a large piece. Would you have any suggestions for what I could try? Thanks, Aaron.

Can you explain why the towel is applied to the side that has swollen? Should it not be put on the side that is dryer so that it swells to equalize the moisture? I realize what you did worked, it is just unclear to me why.

My high school Industrial Arts teacher, back in the mid ’40’s, taught us how to take the warp out of boards by watering down the concave side and then heating the back side with a propane torch. Takes a while & you have to be careful not to scorch the wood, but it works.

I have have had luck placing cupped boards bowed side up on dew covered grass in direct sunlight, and leaving it lay for several hours. Works for me.

This is what I was taught too, way back. With one more step. Once the panel is flat, clamp it down to hold it flat while it dries. The problem is that according to the wood-technology theory of compression shrinkage, and my experience too, you’re making the warp worse over time. I wonder if you have checked the results of your attempts after a year or more? That’s the reason I showed the pine board after more than a year.

I have straightened cupped cabinet doors by soaking them thoroughly in hot water then clamping them flat with alternate clamps and placing them in the sun to dry, turning them over several times as the unit dries.