We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I like good ideas. I wrote “The Homemade Workshop: Build Your Own Woodworking Machines & Jigs” to show regular woodworkers the potential of a little creative thinking. Whether it be full-on homemade woodworking machines, or simple workshop hacks, there’s always a certain satisfaction that comes with implementing a new idea. Here are a few practical workshop ideas you may not have thought of:

I like good ideas. I wrote “The Homemade Workshop: Build Your Own Woodworking Machines & Jigs” to show regular woodworkers the potential of a little creative thinking. Whether it be full-on homemade woodworking machines, or simple workshop hacks, there’s always a certain satisfaction that comes with implementing a new idea. Here are a few practical workshop ideas you may not have thought of:

Get an electric pencil sharpener

My relationship with my electric pencil sharpener borders on weird. I remember using it in one of the first videos I made for YouTube, then turning to the camera and saying “If you don’t have an electric pencil sharpener in your shop, why are you even in this business?” I meant it then, and I mean it now. Today’s craft is dominated by power tools. We mill our wood, cut our wood, shape our wood, sand our wood and even finish our wood with tools that plug in. I can’t even use a screw driver without feeling like some sort of caveman. So why would I manually twist a little sharpener on the end of my pencil, risking wrist strain or tendinitis, when I can stick it in a hole and let a machine grind it to a perfect point in two seconds? We’re not living in the middle ages, folks. Get with the times!

Don’t throw your trash bags away

Before you laugh at ol’ Captain Obvious, hear me out. Trash bags aren’t just for trash anymore. You can slip one on each leg, secure at the knees with duct tape, and use them to keep your son’s feet dry at the bus stop while simultaneously ruining sixth grade for him (thanks, dad). Or you can use them in the workshop the next time you mill stock for a project. Jointing and planing may make a board flat, but they also expose the moist middle of your project’s parts. As that moisture dissipates it can lead to cupping. So if you won’t be assembling your project immediately, place your parts in a trash bag. This will minimize moisture changes and keep your stock flat.

Steal a rubber spatula

Years ago, my wife caught me with the rubber spatula in my hand and cake batter on my face. You can imagine how embarrassing that was, especially since neither of us had recently made a cake. She looked at me, I looked at her and I quietly said “I need this.” I wasn’t just talking about the cake batter. I find rubber spatulas to be excellent glue spreaders, especially on large areas. And the best part is, the dried glue peels right off of it. I still use that spatula all the time, as well as a few other sizes I’ve picked up at dollar stores.

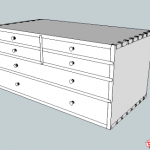

Save those CD spindles

This idea may be getting a little dated, but I still buy those big stacks of blank CD’s that come on spindles with twist-on plastic covers. The thing is, I don’t buy them for the CD’s. I buy them for the spindles. If you break the center post off, you can fasten the base to the underside of a cabinet and fill the bowl-shaped cover with bolts, screws, snack mixes, you name it. They hang upside down and make excellent storage containers because you can easily see what’s inside. Now, if I could only find a use for all those blank CD’s that come in them…

Hoard inline roller skates

One of my best ideas came to me while lying on the pavement gasping for air with skinned knees and a bruised ego. I discovered that I had been using my inline roller skates the wrong way. Rather than trying to impress the neighborhood ladies with my “blading” skills, I could remove the wheels and harvest the bearings. Every pair of skates yields sixteen sealed ball bearings of about three quarters of an inch in diameter. That’s the perfect size for all sorts of applications, from homemade band saw blade guides to tracking mechanisms for horizontal routing machines. If you don’t have a pair of inline skates laying around, you can usually pick them up for about five dollars at yard sales and flea markets. If you need ideas on how to use them, along with all sorts of other cool homemade woodworking machines, might I suggest picking up a copy of “The Homemade Workshop?” I know the author. He’s definitely someone you should check out!

James Hamilton is the man behind the popular Stumpy Nubs Woodworking website. He makes it his mission to find and share new and innovative ways to streamline workflow in the shop. His book “The Homemade Workshop” is available now at shopwoodworking.com.

James Hamilton is the man behind the popular Stumpy Nubs Woodworking website. He makes it his mission to find and share new and innovative ways to streamline workflow in the shop. His book “The Homemade Workshop” is available now at shopwoodworking.com.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

James Hamilton said: “Now, if I could only find a use for all those blank CD’s that come in them…”.

Jeff Polaski answers: “When I have to drill a hole straight into a flat surface, not having a drill press, I start the pilot hole, place the CD shiny side up with the center hole over the pilot hole, and drill straight down using the 360 degree view of the drill bit to line up the bit with the reflection so that the bit and the reflection are totally in line with each other.”

Also check the local dump / transfer station. Sometimes, there is a “swap” pile that may have used roller blades. To clean the bearings, soak them in naptha over night and scrub with an old toothbrush.

I have a couple of other common items that I keep and use in the shop. The first is the above mentioned toothbrush. Great for cleaning and scrubbing machine tool parts, faux finishing, etc. Put them in the dishwasher or in a 10-20% Clorox solution to clean before using, if you’re paranoid about the germs.

The second items I keep in the shop are old plastic key cards, credit cards, gift cards, etc. They make excellent glue spreaders and shims. I usually notch them w/ a pair of diagonal cutters, or a saw, to provide an even distribution of glue, similar to a notched mason’s trowel. They also work well for mixing small batches of epoxy and paint.