We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The Dremel 3D45 is a particularly easy-to-use 3D printer. Easy to learn. Easy to run.

With prices dropping rapidly, there’s a lot of interest in 3D printers these days. Since a 3D printer can make useful things for woodworkers, it’s a time for an introduction and product review. Though, I use them a lot, reviewing 3D printers is not my specialty. From a woodworking writer’s perspective, I’m more interested in investigating how woodworkers can use them and exploring new uses for these amazing digital tools. I’ll leave more detailed reviews to reviewers who specialize in 3D printers. If you need more information about 3D printers and techniques and want to dive deeper, here are three YouTube sources that I recommend: Tom Sanladerer, Maker’s Muse, 3D Printing Nerd.

The Dremel DigiLab Collection of Digital Tools

Dremel is a name known to woodworkers and just about any type of craftsman or hobbyist. Their rotary tools are so well known that the name Dremel has almost become a verb. These handy tools are sure to be found in the toolboxes of jewelers, model builders and nearly every woodworker who has a use for a small, precise tool for detail work, carving, sanding, grinding or engraving. Dremel rotary tools are simple to use, inexpensive and can be found at any home improvement center and woodworking store.

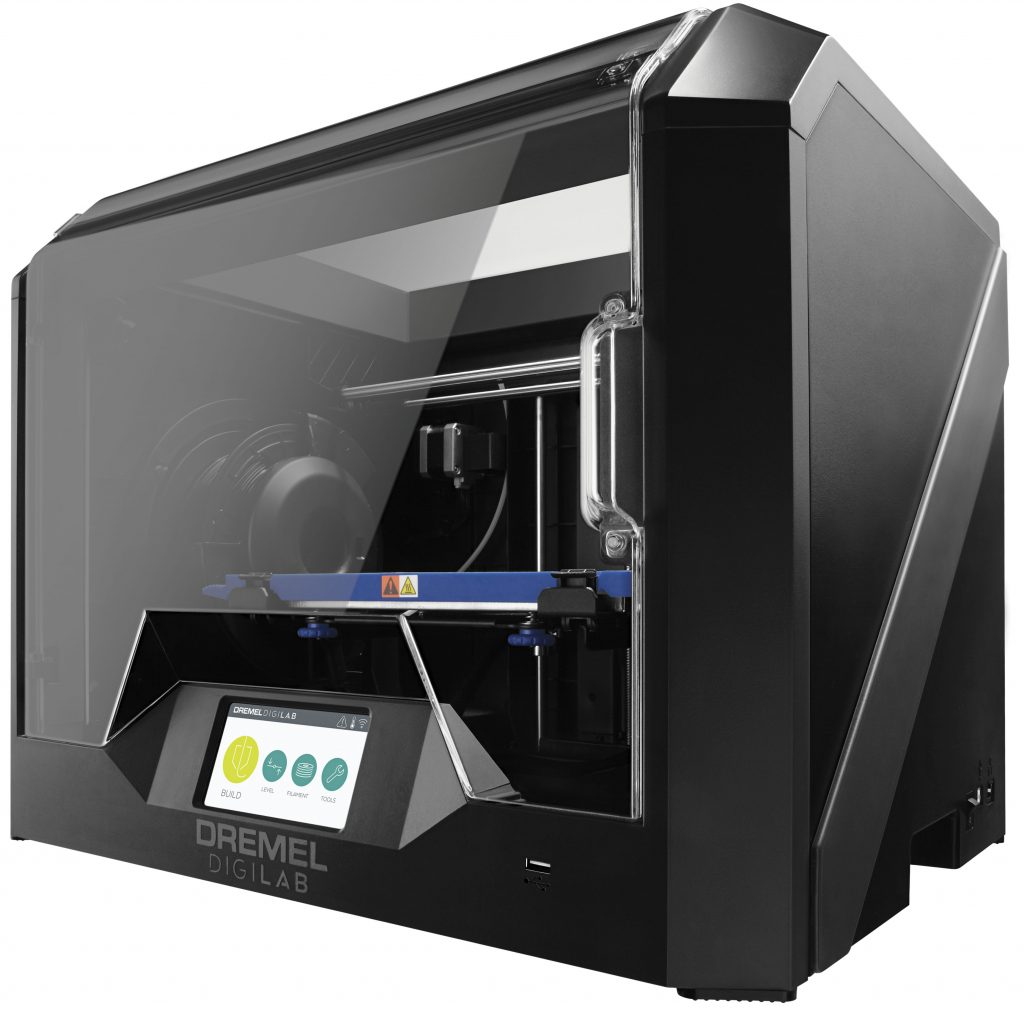

A few years ago, Dremel began to look beyond the small power tools they’re known for to assemble the DigiLab collection of digital tools. They started with a series of 3D printers and recently they added a Laser Cutter. The company began with entry-level 3D printers and have expanded their line to include a new printer capable of handling more challenging materials: ABS plastic, PETG, and Nylon. Unlike the PLA plastics that are commonly used in 3D printing, these materials add toughness, strength and/or flexibility. They also happen to be appropriate materials for making useful things around a woodworker’s shop. Dremel’s new printer is the DigiLab 3D45 and with its ease of use and added capabilities, I thought it would be of particular interest to woodworkers, so I requested one for review. Let’s have a look.

3D Printing

First a little 3D printing background. There are over a dozen major methods of doing 3D printing. The 3D45 and other Dremel printers use what is called a Fusion Deposition Modeling (FDM) printer. FDM printers use filament in the form of wire, rolled onto spools that are made from a variety of plastics and other polymers. The printer feeds the material through an extruder that heats and precisely dispenses it in very thin layers, one on top of another to ultimately form the intended three-dimensional object. This printing method is the most popular 3D technology. The result is over the last few years, FDM printers have become much more common and prices have dropped rapidly.

3D printers cost anywhere from $2-800 for imported kits that are often challenging to get working right, to thousands and well beyond for engineering prototype capable machines. What the Dremel 3D45 offers are many of the most desirable capabilities and features of engineering-type machines at a price of $1799. The nearest comparison to the 3D45 in size, capability, is the MakerBot Replicator+ at $2499.

As with any 3D printer, it’s important to look beyond price alone. In this case, the Dremel 3D45 comes with important bonuses: it’s a very simple 3D printer to use and it just works. The printers simplicity and it capability to work with new materials are the reasons why I wanted to review it for Popular Woodworking readers.

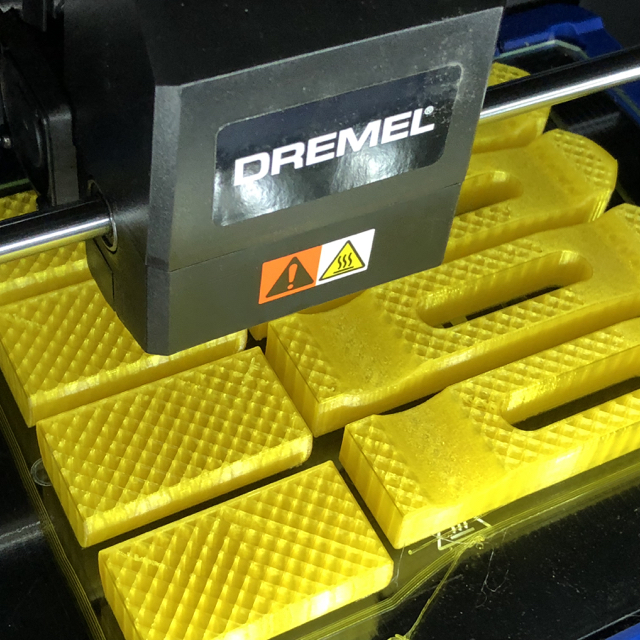

There are a lot of things woodworkers can do with a 3D printer. In this photo, I’m printing out clamps for holding work down on my CNC.

Testing different clamp design and construction. 3D printing is simple and cheap. That makes it easy to try out designs to see what works best.

3D Printer Considerations

Besides price, there are other things a buyer should keep in mind before purchasing a 3D printer. The first is the size of the print area or print volume. The 3D45 has a 25.5 x 15.5 x 17.0 cm (10 x 6 x 6.7”) build volume. There are bigger printers out there, but for woodworkers intent on making project components or shop needs and for most general 3D printing, this is a very useful size. The next thing to look at is the temperature ranges of the nozzle and bed. This affects the materials a printer can handle. The Dremel can print materials from common PLA to PETG, ABS, Nylon and even TPU — a flexible plastic. Unless you’re an engineer making rugged prototypes from more exotic materials that require higher temperatures, this a good range of materials to work in.

The important detail to consider is something often overlooked: the design and construction of the printer. These are important factors that affect the quality of your prints. Besides stability, there are advantages to different printer design formats. Many 3D printer designs work well, but some designs have particular advantages. The Dremel 3D printers use a fixed, overhead X/Y design with a moving Z or vertical axis inside an enclosure feeding filament through a direct drive extruder. This format requires good engineering and solid product design. The advantage of this design is that it delivers consistent layering from the bottom to the top of a print. Building all this inside an enclosure requires design, engineering, and manufacturing commitment.

The Dremel 3D45 comes complete with everything you need including ABS like plastic and nylon filament.

The Dremel DigiLab 3D45 Idea Builder

Because the Dremel is built inside an enclosure, the 3D45 is able to control the temperature within its workspace. Drafts and temperature changes are some of the reasons that it’s difficult to print temperature-sensitive materials. Without an enclosure, prints in Nylon or ABS often warp or pull off the print bed. Again, these are desirable materials for producing components for jigs, fixture components, and clamps. Another feature is the Dremel filters the air as it exhausts the enclosure. This is particularly important for printing ABS plastics that can have a noticeable smell when hot.

The 3D45 uses a color touch screen interface. It’s attractive and responds well to the touch, but I found that the type font too small and light for the small screen and some menu options hard to get to.

A Particularly Friendly Printer

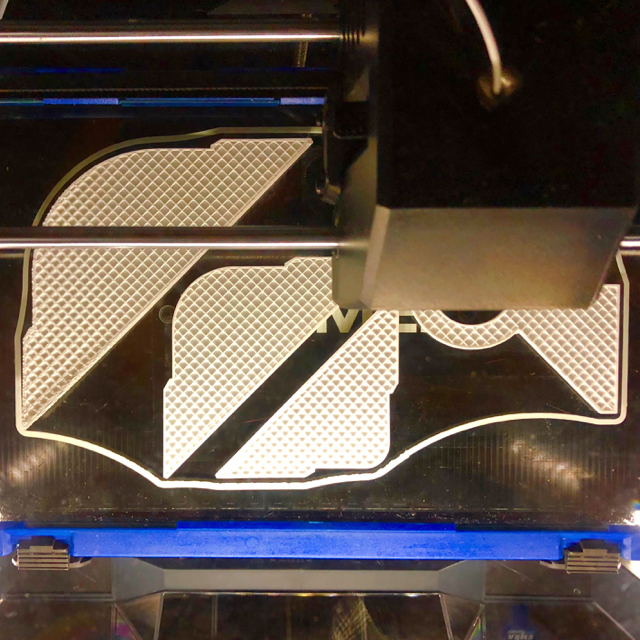

I’ve been using 3D printers for a while and the Dremel 3D45 is the simplest and easiest printer to operate I’ve used. The most common 3D filament is PLA (polylactic acid), a bio-degradable derivative of corn or other plant starches. With a little practice, most 3D printers can handle it well. On the Dremel, perfect results with PLA happen the first time. Even better, right out of the box, I was also able to make excellent prints in ABS and nylon. This almost never happens. Usually, a lot of fussing of temperatures and settings is involved dialing in these materials. On the 3D45, it’s easy.

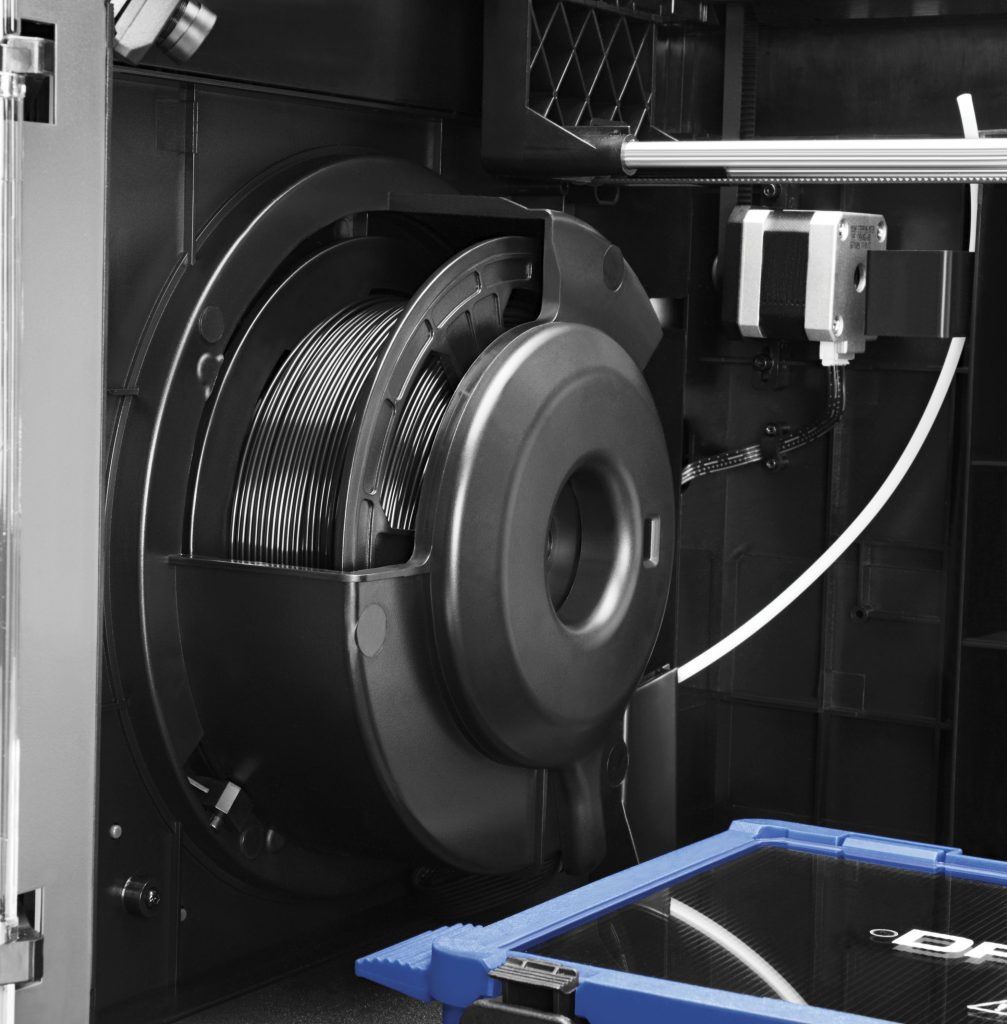

How does Dremel do it? They’ve taken a number of approaches to achieve perfect results. For some materials, the temperature-controlled enclosure is important, but Dremel has taken control a step further. They’ve tuned the printer along with Dremel’s own printing materials to simplify and automate the process of 3D printing. With Dremel brand filament, each reel comes with an embedded chip that talks to an RFID reader inside the printer enclosure. Once loaded, the printer recognizes the filament and adjusts the print settings accordingly. This makes 3D printing very easy and the consistent results speak for themselves.

Though generally excellent in quality, Dremel filament comes with a few trade-offs. The most obvious is the reels are smaller with only 1/2 Kg of filament compared to the norm of 1 Kg spools. There is also a limited range of colors and material types. This makes the cost of Dremel filament about 1.5 – 2 times more than you might pay for comparable materials from other sources.

Though there are several advantages to the Dremel brand filament, you’re not limited to using it. When using a third-party filament, you won’t get all the automatic setting and fine-tuning the Dremel printer offers.

How well do other filaments work? In practice, I found that the printer works fine for other brands as long as the filament is of good quality. By that I mean, super cheap, imported filaments could be more troublesome and require tuning, bed adhesive, etc when compared to better quality filaments. To various degrees, this is also true with other 3D printers. But, with the better quality filaments I prefer priced from $15-$30+ a kilogram, I had no trouble printing them on the 3D45.

The filament is loaded into the Dremel enclosure from the side through this door. It works great for Dremel branded filament, but there’s no easy way to use the larger reel sizes common to third part filaments.

Inside view of a filament reel in is the holder. Inside is an RFID sensor that detects the filament loaded into the 3D45. This allows the printer to automatically set all the settings needed for a specific filament type (PLA, PETG, ABS, Nylon, etc). Neat!

The Enclosure

Using third-party filament on the Dremel printer comes with a few practical trade-offs, thanks to the design of the enclosure. The case is designed to only handle only Dremel filament reels inside the case. The reels are small and every other reel I tried, will not physically fit inside the enclosure. That makes using loading and handling alternate filaments awkward and inconvenient. So, users of third-party filaments will have to come up with ways to hold spools and dispense filament from outside to inside the printer. It took 3 or 4 attempts before I came up with a working solution. I’m hardly alone. There are a number of free designs for reel holders for Dremel printers at thingiverse.com, but even then, I found most solutions far from elegant. I ended up using a simple roller setup to feed filament from near the reel opening on the side of the printer.

If it was my printer, I would tackle this problem and create a design for a reel dispenser to work outside of the printer and feed filament via a port through a hole drilled in the back of the enclosure. Though it would certainly work, a far better solution is for Dremel to design future enclosures to hold all standard reel sizes inside the case. Or, at least come up with a more accommodating solution to handling third-party filaments. Their well tested filaments combined with the printer’s auto-detect features make a convincing case for using Dremel branded filament. These automatic features make 3D printing simple and are worth the cost for many users. But, the availability of many amazing filaments for 3D printers is helping drive growing 3D printer sales. To take advantage of it, Dremel needs to find a way to make using third party materials less difficult.

Ease of Use

Ease of use is one of the 3D45’s best features. Besides delivering excellent results in a range of materials, Dremel has gone out of their way to make interacting with the printer easy and friendly. As a digital tool, I would not call 3D printing difficult, particularly when compared to CNC machining. But, when starting out 3D printing can be a bit fussy until you get the hang of it. Not so much with the 3D45. Dremel’s combined solution of well-engineered printers, matched materials and simplified operation have gone a long way to making 3D printing simple and easy.

To prepare a design for printing, all 3D printers use computer programs referred to as “slicers”. They’re something like the CAM software that CNC users use. These programs prepare your 3D files and set up the machine for printing. Compared to CAM software, slicers are much easier to use. You only have to make a few basic decisions regarding materials, speed, and quality and away you go. Dremel’s filament detection system makes it even easier. So, all you really have to do is make a choice of the quality level of your print and go. It’s that simple.

The software is Cura based, easy to use and is able to make create custom printing profiles. In other words, you can save optimized settings for a favorite filament and select them as needed without having to fuss and enter new settings each time you print. A few clicks and you’re printing.

Once your files are ready to print, Dremel gives you choices on how to load the file into the printer. You can put the print-ready file (its a Gcode file, just like CNCs use) onto a flash drive and plug it into a USB port on the printer. Better yet, via a WiFi connection, you can wirelessly send a print job from your computer. As a bonus, the 3D45 has a built-in camera so you can watch your printer remotely as it’s doing its thing. With the Dremel, I could sit in my living room with a laptop and send print jobs to the printer in my basement. These are features I came to enjoy and miss on my other printers. And if you have a number of printers, referred to as a printer farm, you can manage all the printers remotely.

Speaking of watching, if you didn’t already know, watching a 3D printer do its thing is equivalent of watching paint dry, only much slower. 3D printing is not a fast process, it just takes a very long time, and the Dremel is no different. Depending on the size and complexity of a print, times can range from a few hours to a few days. It’s not hard to understand why if you analyze what the machine is doing. Dispensing layers a fraction of a millimeter thick just takes a lot of time to build a model. It’s just the way it is. I often watch the first 5 minutes of a print to ensure the first few layers are going down correctly, then once satisfied, I leave the room not to return many hours, or sometimes a day later.

Other things I like on the 3D45: The touchscreen interface on the printer. Most 3D printers, even some expensive ones use one button controls and LCD screens. The Dremel uses a color touch screen. Because the printer is connected to wifi, it also keeps in touch with Dremel cloud servers to keep the software up-to-date. And, through the Dremel online service you can access other features and models to print.

The Dremel is printing out a set of corner rounding templates that I can use with a router to perfectly round over corners.

The Dremel 3D45 as a Tool

I’ve never met a woodworker who wasn’t a tool aficionado. We all seem to like high-quality, well-made tools. Certainly, woodworkers who use digital tools like quality tools, too. So, from a tool person’s perspective, how well does the Dremel 3D printer measure up? Quite well, actually. Unlike many cheap, imported printers that often feel a bit spindly and are fussy and need a lot of fiddling to get right, the 3D45 is a solid product. Though there are some excellent, industrial grade machines out there for a lot of money, in its price range the Dremel is the first 3D printer that could be fairly considered a fully-designed and engineered consumer product. Many 3D printers look like and are a collection of parts. Not the Dremel. Unlike lesser printers, the 3D45 uses many custom-molded, cast and extruded parts in its construction and it looks and feels like a complete product. Add the simplicity of use and the quality and consistency of the prints it delivers are the result.

A word of warning about 3D printers and woodworking. 3D printers don’t mix well with the dust we create in a woodworking shop. Hot plastic is like a magnet for any kind of dust. It only takes a single spec to ruin a print. If you get a 3D printer, I strongly recommend that you don’t locate it in your shop. Keep it in your house or office. My printers are located in a spare room. Fortunately, unlike CNCs which are seriously noisy, most modern 3D printers are quiet when running and the Dremel with its Trinamic drivers and stepper motors is particularly quiet.

Conclusion

The Dremel 3D45 3D printer is a good tool made by a company known for making good tools. I got a lot of use out of the review unit making jigs, clamps, design prototypes and other 3D designs before returning it. With designed-in simplicity and a focus on getting good results quickly for newbies, it’s an easy 3D printer to recommend. If you’re thinking about 3D printing, the Dremel 3D45 printer is worth your consideration. This is a 3D printer that just works. And, it’s easy to use —something you can’t say about many other printers.

For woodworkers, the 3D45’s ability to work with a wide range of materials that can make more rugged parts for use in the shop is definitely a bonus. And, consider this: unlike pretty much every tool we use in a woodworking shop, this is a tool that every member of your family can use, safely. Pick a design (there are literally millions of free designs available online at thingiverse.com), pick a filament color, click, print. Who knows, maybe the younger members of your family can teach you a trick or two.

Recommendations

Things I like:

- Solid engineering, design, and construction.

- Emphasis on ease-of-use.

- Easy-to-use temperature controlled enclosure with two easy access doors and filtered ventilation.

- The enclosure makes the printer safe from little fingers touching things they shouldn’t touch. This is one of the reasons that Dremel 3D printers are so popular in schools.

- Color touchscreen interface.

- When using Dremel filaments, the auto-detection features make 3D printing very easy.

- Semi-automatic bed leveling

- Removable glass print bed

- The online setup, support site, and technical support are excellent

- Each printer is calibrated and tested before shipping

- Enclosed power supply and electronics.

- Uses state-of-the-art components like Trinamic motion control drivers for consistency, accuracy and quiet operation.

- Cura-based software slicer is capable and easy to use

- This is a networked printer with Wifi connections and an HD camera. Makes managing one remotely easy.

Things that could be improved:

- The enclosure design makes using third-party filaments awkward and challenging.

- Feeding the filament into the printer is like threading a needle. A port to the PTFE tube would make it easier.

- The filament feed path is convoluted. Occasional broken filament at the top of the extruder because of sharp turns are the result.

- The touchscreen interface design could be better. It looks as if it was developed on a large screen and scaled down. The screen’s typeface is too small, too light and difficult to read for a small touchscreen. Some menu sections are hard to find. A preview of the object to be printed would be a great addition.

- The removable glass print surface works great, particularly for printing ABS and Nylon. But, removing prints from a glass bed is always a challenge. A coated spring steel or flexible print surface that pops off prints would be a great option.

- Inability to adjust temperatures and other settings on the fly without pausing a print.

- The printed manual is just like the ones that come with every Dremel or Bosch power tool. I have dozens of Bosch power tools, so that’s not a compliment. 3D printers deserve better-designed manuals that guide new users through basic procedures and exercises.

Related Posts

Additional Resources

- Digital Woodworking on Instagram

- Personal Work on Instagram

- Digital Woodworking YouTube Channel

Popularwoodworking.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com and affiliated websites.

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.