We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

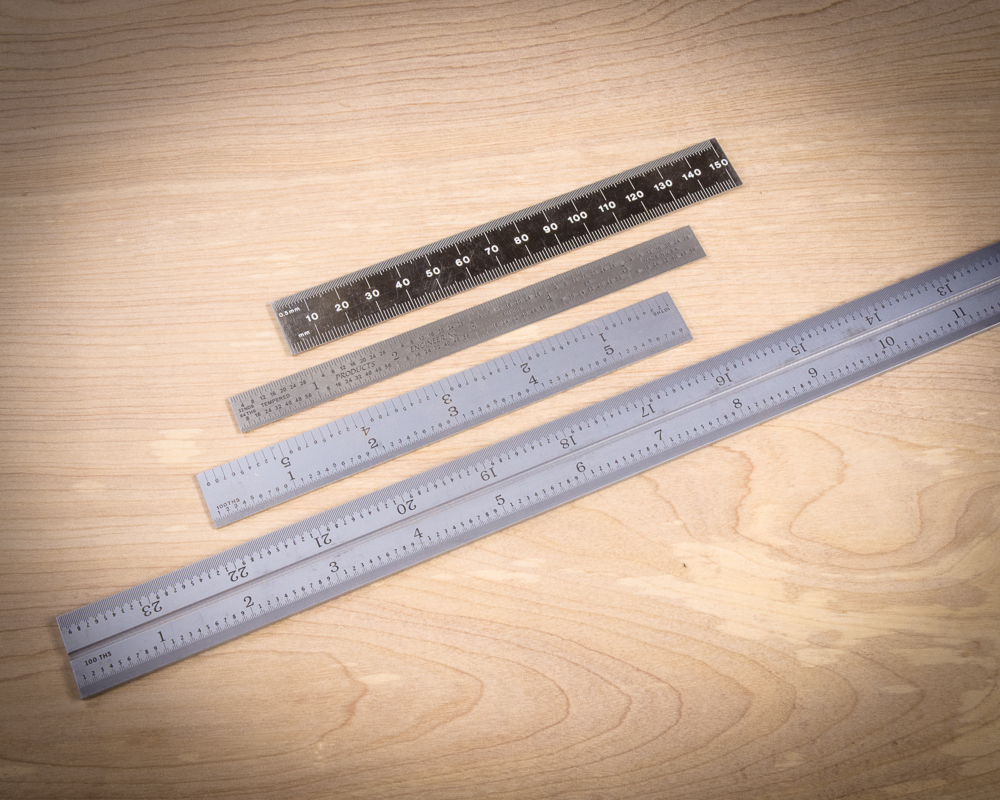

My daily rules. The one in black is metric. The small stainless rule is kept in my apron pocket, 6″ and 24″ PEC rules are in 5R format which is in 10ths and 100ths of an inch — decimals are very helpful if you use CAD and CNCs. Easier than constantly converting inch fractions.

Tapes and Rulers

Early on, I remember reading somewhere that you should never rely on measuring tapes in a woodworking shop. Only use your rulers, never tapes. Though I understand the conclusion suggested because tapes are heavily used and vulnerable, I thought it seemed an odd idea. In practice, I neither agree with nor follow that rule. Because I make furniture — where many part dimensions are longer than most rules, I find that using them too impractical and inconvenient in most situations.

I also don’t believe in the concept of “good tapes” and “bad tapes” though I know a lot of woodworkers that do. Only “good tapes” are allowed in my shop. I go to a lot of trouble to qualify all my measuring tapes and check them regularly. If something isn’t up to snuff, it’s immediately removed from the shop. Using the same thinking, I spend whatever time it takes to tune table and miter saws, jointers, planers and sanders and other fixed tools so they all match my standard setting instruments, that way I can rely on them. My point being, that after qualifying and testing every tool and measuring device in the shop, I rely on all of them because they’re all the same. I need to know that everything involving measurements in my shop agrees with the other and can be trusted. Doing this makes life so much easier. They way you do this is by using standards set by your most accurate tools: precision rules.

Precision Rules

Like many woodworkers, I have rules of various sizes. My most used models are 12” to 24” long Starretts or PECs. I always buy the thick, heavy versions. I have a few 36” and 48” PEC rulers that come out as needed and some even longer straight edges. In my apron pocket, I carry a 6” rule. In another pocket is a 6” combination square. For a long time, I would buy my rules in what’s called 4R configuration. This is the most common format for woodworkers. That means 8th and 16th front and 32

For a long time, I would buy my rules in what’s called 4R configuration. This is the most common format for woodworkers. That means 8th and 16th front and 32nd and 64th on the other side of the ruler. 16R rules take this one more step to 64ths and128ths. That gets really hard to see. Lately, I’ve been assembling a set of 5R format rules which are 10ths and 100ths on one side because these are the units I use in CAD and for CNC work. It’s just so much easier to do things in base 10 if digital is involved. This is the standard ruler format for the aircraft industry and I have to say after using it for a while, I really like it. I also have metric rules, and a few combined E/R rules. To avoid confusion with other rulers, I try to buy metric rulers with a distinctive or reversed black finish. It works.

Tape Measures

Anyone that’s worked with me or taken my classes will tell you that I’m a bit obsessive about my tape measures — so, as you read ahead consider yourself warned. It’s simple, really. I like to trust my tapes. Only good tapes are allowed to live in my shop. I expect them to be as close the accuracy of my very accurate rules as possible. I also consider it critical that all the tapes in my shop are tested so that I can trust whatever one I happen to have in my hand at the time. To do that, I have a picky process in place for selecting my tape measures.

When I’m in production mode, building a lot of furniture, I rely on two matched tapes in my shop. One is always in an apron pocket — my shop apron is home base for me. The other is a floater that moves around key locations in the shop. As a furniture maker with a large backlog of orders, I often work with an assistant who also carries a matching tape. The key word here is “matching”. All tapes are the same and tested regularly against my standards: Starrett rulers.

Tape Choices

There are all kinds of tape sizes and configurations and choices, but when it comes to personal preference, I’ve found for furniture work, a 16’ long by 3/4” wide tape, with measurements on both edges, is perfect for US-based furniture making. With this selection, I’m inferring that we’re stuck with the Imperial system for measurement and materials, for the time being at least. I’ve found that this model is long enough to measure imported and domestic hardwood lumber commonly available up to 14’ long, yet wide enough to have a decent standout, doesn’t get damaged as easily as smaller tapes and yet, compact and light enough to comfortably fit in my apron pocket.

I’m not a fan of unnecessary size, bulk or added cladding on a tape. These added features are for contractors and carpenters, not woodworkers. A furniture maker’s shop is just not the same as a job site where dropping a tape from a ladder is inevitable. Besides, I don’t drop things. Also, I prefer bright colored tape measures over shiny metal ones that are also heavier. As parts and sawdust pile up on shop surfaces, a left-behind tape is hard to find. I’ve found that color really helps. Next, I only use thumb lock tapes. I have yet to find any form of a spring held tape to be anywhere close to reliable and I’ve tried a lot of them.

When you’re out buying tape measures, take along a precision ruler to test each tape.

Buying Tape Measures

How I select my tapes is a process in itself. It’s fair to say that I don’t exactly buy off the rack. For years, I would go to local home centers and woodworking stores with a trusted Starrett ruler in hand to try each tape before I buy. As I enter the store, I just walk up to the manager, ruler in hand and explain to them what I’m up to and head back to appropriate aisle. Once there, I find the model I’m after and start testing. I put on a strong set of reading glasses and if the extended length doesn’t align dead center with my 12” and 18” ruler marks, I move on. I also check the pushed in position. Finally, I carefully check the hooks and rivets to see if something is bent or out of alignment. Unfortunately, over the last 15 years, I would say only 15-20% of the tapes I try, pass these tests. If I find good ones, I buy and use tapes in sets, so I purchase 2-4 at a time.

Back at my shop, I double check the new recruits with even longer very accurate Starrett and PEC rules — just in case. Finally, I use a Sharpie and write the purchase date on the back of each tape to serve as a reminder to recheck accuracy, periodically. Once a tape is no longer up to snuff, it’s marked with an X and immediately removed from the shop to spend its retirement life on garage/household/property owner duties. Unfortunately, my retirement community has really grown over the last 20 years. How big? Let’s just say, I’m not wanting for tapes and could possibly equip a major commercial construction project. I’ve got tapes scattered everywhere. Drawers, glove boxes, gift wrap room, exhibition setup boxes. Everywhere.

Though I’m very careful with all my tools, my measuring tapes typically are on duty only for 6 months to a year or so before they fail qualification. Famous brands, lesser knowns, new brands, I’ve tried them all. Barely stretched tapes or bent hooks, slightly worn rivets or rivet holes or the rare kink are enough for me to retire a tape to less-critical tasks if it no longer meets my standards. That’s the way it’s been for decades…until recently.

Best tapes measures I’ve ever used. All test perfect and stay that way thanks to excellent design. Readability is outstanding. Tajima tape measures come in various configurations. My personal preference is 16’/5-meter in bright yellow — so I can easily find them under piles of sawdust.

Being so picky about measuring tapes, I pay a lot of attention to design, engineering, casting, construction and every little detail that goes into tape measures. About six years ago, I qualified and brought home two well-engineered Fisco Class 1 grade (this means a minimum accuracy of .3mm over 2 meters) tapes made in the UK that had an added feature: a bump stop or shock absorber to protect the blade and hook when it comes crashing home. The tapes also have very rigid hooks and bigger rivets. I first thought the bumper was a gimmick. It is not. Even after years of use, those two tapes are still in my shop and remain accurate to this day. There’s a lesson, here that I’ve taken to heart in my search for new tapes.

A few years ago I started buying a Japanese brand of tapes called Tajima and I’ve never looked back. They are not easy to find, but US distribution is starting to pick up. With family in the Berkeley, CA area I visit regularly, I buy my tapes from the Hida Tools store. They specialize in Japanese woodworking tools. Wonderful store for woodworkers. So many temptations.

Tajima tapes have most rigid and best hook and rivet design I’ve ever seen, a true shock absorber to cushion retraction and the best readability and construction of any tape I’m aware of. As a bonus, they’re compact, colored bright yellow and come with out-of-the-box perfection. They cost a bit more than the tapes you’ll find at a home center, but for me, at least, they’re well worth it. For the first time, every tape I’ve purchased is perfect. I’m so enthusiastic that I now buy cases of them and have shared many with students and woodworking friends.

Tape Preferences

With the introduction of CNCs in my work and a growing focus on fine art, my preferences in tape configurations have also changed. Tajima tapes come in various versions and and lengths. I’ve moved from my standard 3/4’ – 16’ tape to a 1” wide, Tajima D-TA-H5-16BW, which is a very compact combination 16’/ 5-meter tape.

When it comes to measuring systems, I’m kind of mid-evolution. My established collection of furniture designs are imperial —I’m not going to change what I’ve already created. Art, sculpture and new furniture designs are moving in the direction of metric. Some CNC work is metric based, so these tapes help. As a bonus, if you regularly use a combination tape, you’ll find that staring at both measurements starts to tune your brain to convert between the two systems. There’s an added benefit. Sometimes when taking a measurement that falls inconveniently between numbers, say 11-1/8” and 11-1/16”, having metric nearby gives another set of marks to use when transferring a measurement.

With added focus on fine art, my work habits have changed, too, so I now keep four tapes active at a time, one in my apron, the others around my shop. After a lot of use, I’ve found that Tajima tapes are a delight to use and I’ve yet to retire a single one. What can I say? After decades of searching, I’ve finally found tape measures I really like. It looks like my long journey to tape measure perfection is finally over. If you’re a picky woodworker like me and rely on your tapes a lot, check them out.

Next up: Tools for precision work. Calipers, micrometers, dial indicators and more.

Additional Resources

- All posts on Precision Instruments, click here

- Digital Woodworking on Instagram

- Personal Work on Instagram

- Digital Woodworking YouTube Channel

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.