We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

Meet the artists from the December 2017 issue

How five masterful makers integrate CNC and CAD technology into their woodworking

In the December 2017 issue of Popular Woodworking magazine, the article, Digital Artistry gives the readers a peek at what five professional woodworkers are doing with digital tools in their shops. Each has an extensive traditional woodworking background and many years of experience before they added digital tools like CAD software and CNC machines. All five are friends who meet regularly as a group, to exchange ideas and techniques as we explore this new digital world.

For the print article, I thought it would be more useful for readers if each woodworker would introduce themselves, say something about their backgrounds, their work and how they got started using digital tools. To do this, I sent out a survey to each member of the group with a series of questions.

With the space limitations inherent to print publishing, only a few quotes from each questionnaire made it into the final article. With so much information collected, I thought Popular Woodworking’s readers would like to hear more about each woodworker’s world. So, in this series of posts on Digital Artistry, I’ll share each woodworker’s survey answers with our online readers.

This post is about Seattle area furniture maker, Bob Spangler. Bob is a long time woodworker with an extensive line of beautifully designed contemporary furniture. He’s a long time CAD user and has had a CNC in his shop for less than five years.

A video interview with Bob in his shop…

So, here is Bob Spangler in his own words…

Bob Spangler

Bob, tell us about your woodworking history

Bob, tell us about your woodworking history

I began woodworking in 1973 after working as a Landscape Architect. I found that working with my hands and creating objects that I could touch and sense was extremely gratifying.

Describe what you do as a woodworker

I am mostly a custom furniture maker working in domestic and exotic hardwoods. My work has been included in National shows, public art projects, various publications, competitions and private collections. On larger scale projects, I have collaborated with other artists and design committees. My work is influenced by studying classical American furniture styles, their construction techniques and carving methods, a continuing interest in Asian furniture and the “Northwest Style” of furniture design

Describe your workshop

Describe your workshop

My shop is 3,100 square feet and over the years I have accumulated the tools that I need to do the job at hand.

How and when did you get started using digital woodworking tools? And, why?

My interest in CAD began in about 1994 while working as an Instructional Technician in the Art Dept at the University of Washington. Along with the students their we all began using this as a design tool. Since then I have continued to design with CAD but using it mostly as a presentation tool. I could accurately draw a new design, rotate it to any angle, scale it, etc and then render it and present it to a client. in 2012 or so I developed an interest in CNC routers, mostly to stay “current”. At that time I had no particular project that I needed to use it on. But I did see an over-crowded attic full of the old jigs for various pieces of furniture and realized that CNC files could be stored in much the same way as an attic full of jigs but in a much smaller space. I was also becoming so overloaded with jigs from years of furniture making that I was starting to forget how to actually use these older jigs. CNC files could also help to solve that problem.

How do you use your digital tools?

How do you use your digital tools?

After using the CNC router for a few years, I am continually finding new ways to use it in furniture making. I use the CNC almost exclusively for joinery. I do, however, envy a friend of mine that uses his in a more artistic and creative way by 3D carving. I think my history of being a member of Northwest Gallery of Fine Woodworking and creating furniture in the studio furniture movement that emphasizes quality and perfect joinery has influenced me in the direction of using my CNC for joinery. I am finding that I use it more and more all the time and my joints are perfect.

How did you learn how to use these tools?

Like my woodworking career, I have learned to use the CNC router with the self-taught method. I don’t necessarily recommend this method, it just seems to be in my stars.

What are the challenges you have/had with these tools?

The challenges I have had with the self-taught method are it is an extremely slow way to pick up all the tips for running the machine. I have been using a handheld router for over 40 years but I have never thought about how fast am I actually moving the tools over the surface or what rpm am I using since the handheld router did that for me. The CNC demands answers. It is actually a dumb machine but smart enough to ask questions. It asks a lot of questions, that I have mostly ignored over the years. Hold down is another topic in itself and that requires many different approaches depending on the pieces being cut. In the beginning of using the CNC, the various different pieces of software seemed overwhelming and I find new users often asking me how I learned to know all the math and programming needed to use a CNC. What I found out and most people don’t realize that it is not that difficult. It is a process.

What benefits are you getting out of CAD?

What benefits are you getting out of CAD?

The benefits that I get out of cad are the ease of altering a design and seeing the results that are accurately drawn quickly. Since I basically build a piece of furniture in CAD, I often find problems before I build whereas in the past that might not have been the case. CAD lets me get a drawing out to the client much quicker and I am pretty certain that it will work both in the design — I know it is to scale whereas a hand drawing might not be and also structurally. The client also likes to see these rendered drawings, I often draw some aspects of their actual room so they can easily visualize the piece in the space.

What benefits are you getting out of a using a CNC?

The accuracy and speed at which the CNC can do these tasks are fantastic. In some cases, I can do other things while the CNC is doing something else. I am finding more and more that I am designing with the CNC in mind. The CNC is a little like learning a new language. They always say that when you start dreaming in a new language you are starting to master that language. I am now starting to think — maybe not dreaming yet, as the CNC as my partner and how can we work together.

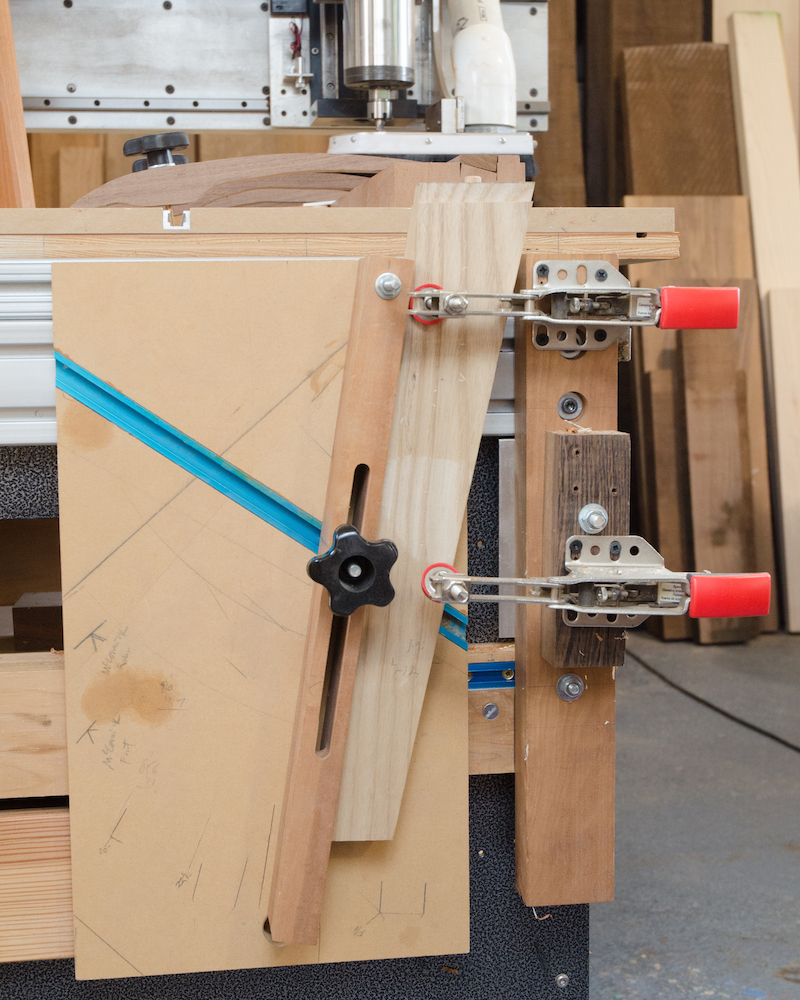

Can you describe your CNC?

My machine is a custom made machine by Carl Bruce, a Seattle area builder of custom CNCs with a 4’ x 6’ working area and it overhangs on the end for joinery. It has a 3hp water-cooled spindle which I find quite adequate for the jobs that I do.

What’s different?

What’s different or surprised you once you started using these tools?

What’s different or surprised you once you started using these tools?

When I first got my machine I talked with a friend of mine that already had a machine. He told me that I would continually find new uses for the CNC and he was certainly correct.

What can you do with these tools that you couldn’t do before?

I am not sure that there are things that I can do now that I could not do before I had a CNC machine. But I can certainly do them faster and more accurately than I could before. Now I can draw a form in CAD for bending and then cut the form. Now I know the form is accurate, I know what the radius of the curve is or the angle and if I need to I can then cut the negative of that as well. This was all possible before CNC but painful.

Has your process changed with these tools? How so?

Has your process changed with these tools? How so?

My process has changed since getting a CNC in that I think more about the process. Now, I might assemble part of something first and then cut mortises into a partially assembled piece. Or, I might cut an angled tenon on a chair leg rather than using a slot mortice as before. With the CNC my processes are continually changing.

Has your woodworking thinking changed by using these tools? If so, how?

With the CNC my designs are evolving more toward a simpler design, not that a simpler design is necessarily easier to build or design. I think that thinking this way is a result of using the CNC.

Describe how your work has changed since you have a CNC in your shop.

Describe how your work has changed since you have a CNC in your shop.

My work has really improved with the CNC.

What do you see in the future for your use of these tools in your shop?

Good question? It’s unlimited.

Final thoughts

Anything more you’d like to add?

Anything else you think potential digital woodworkers should know?

I think it is important for the new user to realize that you don’t need to know a lot of math or be a programmer to use a CNC. This is just another tool and will become a very useful tool for them.

I think it is important for the new user to realize that you don’t need to know a lot of math or be a programmer to use a CNC. This is just another tool and will become a very useful tool for them.

I would encourage new users to form a group — like we did, to help get up to speed and also just keep in touch.

I also think it is important for the new user to really think about what size of CNC machine they need. Do they really need a giant 4’ x 8’ or 10’ industrial machine?

Bob Spangler

Additional Resources

- Bob Spangler’s website click here

- All posts on the featured Digital Artists, click here

- December 2017 Issue of Popular Woodworking click here

- Digital Woodworking on Instagram

- Personal Work on Instagram

- Digital Woodworking YouTube Channel

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.