We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

The portable “Milkman’s Workbench” from the June 2013 issue of Popular Woodworking Magazine has attracted a lot of attention, judging from the e-mail piling up in my Inbox. The No. 1 question: How can I build the bench without wooden bench screws?

One answer: wedges.

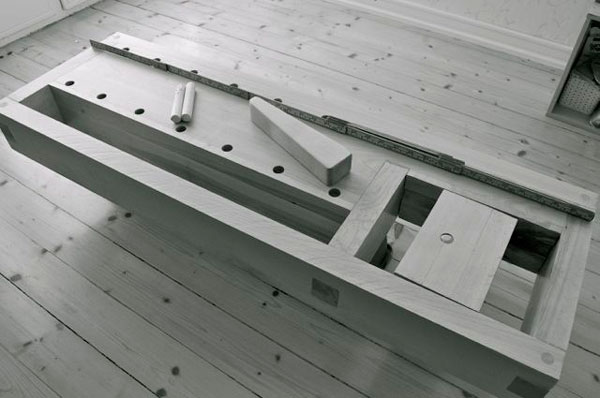

Reader Ilkka Sivonen of FInland built the bench without wooden screws. instead, all the workholding is handled by wedges with a 4° taper.

“To my surprise the wedges work great and provide good workholding,” Ilkka writes. “You don’t even need to tap the wedges with a hammer, a gentle push is enough to provide enough holding pressure. The downside is that you do need several sizes of wedges for different work widths, but at least they are easily replaceable if they break or go missing.”

Ilkka got the idea for the wedge-based system from old photos of workshops. Metal clamps were very expensive in the 18th and 19th centuries (and still are). So many woodworkers made panel-gluing fixtures that were powered by wooden wedges.

Ilkka also pointed out that the wedges shown in the photos are too tall for planing or mortising the books.

— Christopher Schwarz

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

The article in the magazine indicated one could use veneer press screws instead of the wooden screws. What size? One of the Amazon vendors sells Jorgensen 9″, 12″ and 18″. Woodcraft and Lee-Valley no longer appear to sell them.

Hi,

This is way kool but I would like to know who makes the kit that will cut threads large enough for the screws on the vices? All the ones I have seen are too small. Thanks.

I made a workholding attachment for my “Work Area” (it hardly qualifies as a bench) http://www.flickr.com/photos/wb8nbs/sets/72157625378050141/ and struggle with the problem of holding system height interfering with the tools. I have two solutions, raise the work by putting a spacer board underneath, or add a thin spacer board between the vise and the work long enough to clear the tools.

I have a Moxon style vise (inspired by Mr. Schwarz) for holding boards vertically.

Is the Inside, Vertical Face of the Front Frame also made with a corresponding 4 degree Bevel to match the 4 degree surface of the Wedges?

Seems as if this – like the bottom of a conventional Screw Tightened Tail Vise – might “Rack” a bit because of this GAP?

Because the Front Frame is less than 2″ high, an interior face bevel of 4 degrees may not be needed.

drj –

Wonder if this is a nice solution for holding wide boards vertically on a full-sized bench? Does seem to get around the limitations of having a screw in the way.

I would be concerned that it looks like he’s about to plane, chop or bore into one of your books.

-Steve

more dog holes = less wedges?

Nice choice of deal